SERVICE

PAUL DEAN

Con-rods on crack

Q In some magazine tests of motorcycles and cars, I’ve read about certain engines having “cracked” connecting rods. There has been little explanation of what this means, other than one article’s mention of the con rods’ caps being made by a special cracking process. Any chance you could explain? It sounds interesting, but I have no idea what this entails and am eager to learn about it. Steve Archer

Des Moines, lowa

A Traditionally, connecting rods

have been made as one-piece hotsteel forgings with a slightly out-ofround crankpin hole. After cooling, the rod was cut in half across the hole to form the bearing cap, and the mating surfaces of the two resultant pieces were machined to produce a perfectly round plain-bearing-insert mount.

As engines over the years gradually produced more power and turned higher rpm, the forces to which rods were subjected began allowing the bearing cap to shift slightly, causing bearing misalignment. Engineers reacted by installing locating pins between the cap and the rod, which usually solved the problem but introduced even more steps in an already complicated manufacturing process.

As power levels and rpm ceilings continued to escalate, engineers had to find ways to make con-rods lighter and stronger. That goal was accomplished through the development of rods made by a process called powder-metal forging instead of hot-steel forging. They, too, come out of the forge as one-piece units, but with a perfectly round crankpin hole. They also have a granular structure that allows the cap to be separated from the rod through a very precise “cracking” or “fracturing” process. This results in mating surfaces that are

microscopically irregular but perfectly matched to one another. It’s not unlike what happens when you accidentally break a valuable glass object in two and glue the pieces back together: They fit perfectly, the highs of one piece fitting precisely into the lows of the other and vice versa, preventing the two from slipping out of alignment in any direction. With a con-rod, this matching “geography” holds the cap firmly in place, preventing it from shifting under heavy loads. This not only allows the rod to be thinner and lighter, it also simplifies the manufacturing process, in some cases cutting the number of machining steps in half.

Watts the problem?

Q I have a 1985 Honda Magna V30. Sometimes when I am riding, the bike stops and all of the lights go off, then all of a sudden everything starts again. It has done this twice this season

so far. Last year, the engine would just kind of sputter, making me think that maybe the fuel line was crimped. Now, it just totally shuts off and comes on again. Sherri Seeger

Posted on America Online

A Troubleshooting problems of this type on a bike I can't even see is like playing poker blindfolded. But I can tell you that most of the time, a complete power shutdown is the result of a poor battery-cable con nection. On older bikes, the ground cable often is at fault, usually where it bolts to the frame or engine rather than at the battery end. Over time, corrosion around the cable's anchor bolt, often aided by normal engine and road vibration, can cause the con nection to lose its normal metal-tometal contact, resulting in a complete loss of electrical power. Then, the same kind ofjolt or vibration that caused the cable to lose contact in the first place reestablishes continuity, al lowing the electrical system to func tion once again. So, the fix is simple: Carefully check, clean and tighten all battery-cable connections.

If that doesn't remedy the matter, the problem then may be with the ig nition switch. The metal contacts in side that 23-year-old switch may have either loosened or corroded, causing an occasional open circuit that shuts down the electrical system just as though you had turned the ignition key to the Off position. Ignition switches can't easily be repaired, so if yours proves to be faulty, you'll have to track down a new or good used one.

Butterflies are not free

Q I've been casually shopping for a new bike over the past months and have gotten my list nar rowed down to a half-dozen models, some of which have "secondary" throttle butterflies. I know that a lot of bikes in the last couple of years have been equipped with second ary throttles, but I want to know why they are there and if they are a good thing, a bad thing or if it really matters. Duane Ward

Orlando, Florida

A lt does matter, although for most new-bike buyers, the presence or absence of secondary

throttles is neither a deal-maker nor a deal-breaker. The advent of fuel-injection and electronic engine controls has given engineers new and better ways of coping with ever-tightening noise and emissions regulations, and secondary throttles have sprung from those technologies.

In these systems, the twistgrip controls the primary throttle valves via traditional push-pull cables, opening those butterflies in direct proportion to the movement of the grip: One-fourth throttle opens them a quarter of the way, half-throttle does it halfway, full throttle turns them wide-open and so forth. The secondaries, meanwhile, are upstream of the primaries and opened by a servo motor controlled by the ECU-(Engine Control Unit), the main computer that also regulates the ignition and injection systems. Depending upon several factors-including engine rpm at any given road speed the size and power of the engine, the gear in which the bike is traveling-the secondary butterflies may or may not open at the same rate as the primaries. In some circumstances, their rate and degree of opening has been slowed by factory-

determined settings to allow the bike to meet existing sound and/or emissions regulations. In other situations or on other bikes-especially those with large, ultrapowerful engines-the rate of secondary opening lags slightly at lower revs in the first couple of gears to prevent too much power from being sent to the rear wheel too abruptly. And in yet other instances, the secondaries do all the above while also helping improve overall driveability in everyday riding conditions. But in every case, the actual throttle opening that determines the output of the engine is regulated by the secondaries, no matter what the rid-

er does with the primaries. The differential, thankfully, is generally quite small and invisible to the rider.

Feedback Loop

Q I read your comment in the September issue about changing engine oil when hot.

Not sure it totally applies to motorcycles, what with their clean engines and slick oil, but in aircraft, the main reason to drain after running to operating temperature involves suspended particulates. Operating the engine gets as much of the junk as possible into suspension, where it will be drained with the oil. The risk of draining cold is that some of the nastiness will remain at the bottom of the sump, or in places that don’t totally drain during a regular oil change.

Of course, the typical aero piston engine uses 50-weight oil, so a full drain (of six quarts typically, but up to 12 in a flat, opposed engine) would take well through lunch if done cold.

Marc Cook Long Beach, California

A Excellent observation, Marc. As you imply, this is not such a concern with motor cycles, especially if their oil is changed at the prescribed intervals, but it still applies nonetheless. I appreciate the input.

This is not to be confused with the rideby-wire throttles first seen on the Yamaha R6 and now showing up on several more machines, including the new FL Harleys. Those engines have just one set of butterflies whose actual opening is controlled by the computer and a servo motor in response to-but not necessarily in direct proportion to-rider commands. The rider turns the grip to the desired position, and the computer responds in much the same way as with a secondary-butterfly system.

only opening the throttle as fast and far as the computer deems suitable for the pre vailing conditions.

Going by the book

Q In your long-term test fleet, do you go by the manufacturers' recommendations for servicing? Particu larly oil and filter changes? I know some companies recommend long oil-change intervals, with others even suggesting a new filter on every other change. Do you go by these guidelines or do you change oil more frequently, like at 3000-mile intervals? Do you use each bike manu facturer's dino oil and specified weights or do you splurge for the higher-end synthetic oils? Scott Suber

Posted on America Online

A We try to follow manufacturer recommendations for all scheduled maintenance, not just oil changes. Otherwise, the results of our long-term tests would be highly suspect.

The operative word here, though, is “try.” Sometimes, lazy bastards that we are, we miss an oil-change interval by a few hundred miles, and we might not in-

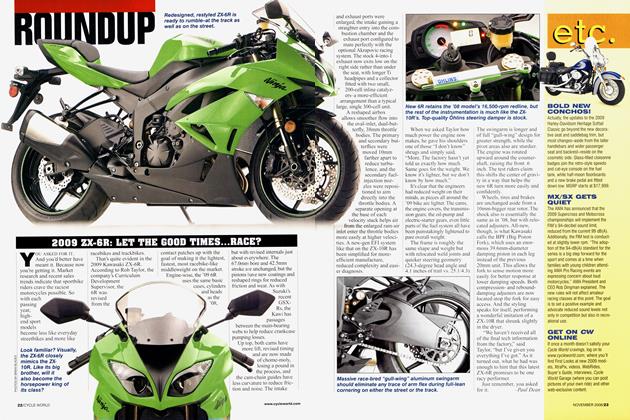

spect the air-filter element or check the steering-head bearings exactly when prescribed. But for the greater part, we endeavor to follow the schedule spelled out in the owner’s manual. When performing oil changes on long-term bikes-such as our ZX-14, which we always ride gingerly, as evidenced by the above photo-we may not necessarily use the brand of oil suggested in the manual, but we always choose a high-quality oil of the specified weight and API or JASO classification. Most of the time, we use either petro-

leum-based oils or synthetic blends, occasionally going for full synthetics when they are strongly recommended by the bike's manufacturer.

Power to the people

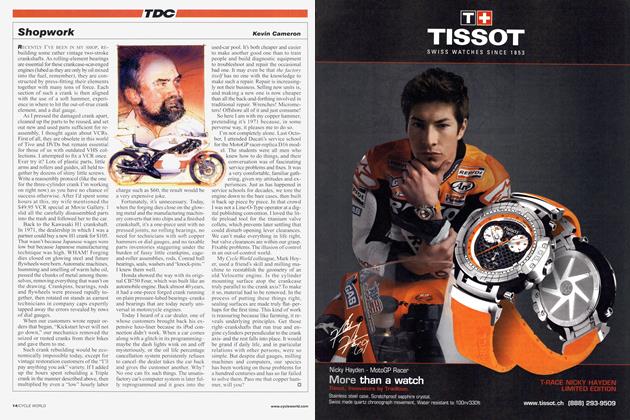

Q I hear a lot of people talking about getting their bikes' frames and other parts powdercoated. I know that powdercoating has indus trial benefits (fewer emissions, great er operational efficiencies, etc.) over

paint, but for the hobbyist/restorer, what are the advantages? In terms of color, durability, fade resistance, repairabilitythings important to me-is powdercoating really any better than a good paint job? If so, what are the keys to getting good quality powdercoating?Tom Sladek Posted on www.cycleworld.com

A Powdercoating originally gained popularity among bike builders as a frame coloring because of its exceptional toughness and durability. It has a much higher resistance to cracking and chipping than regular paint, making it ideal for that application. The front downtubes of bike frames are constantly pelted with stones, grit and other road grime kicked up by the front tire, and the bottom tubes are subject to even more damage because they live so close to the ground. Powdercoating also is generally applied in thicker coats than paint, which can help hide small imperfections in the base metal. And as far as fade resistance is concerned, any differences between paint and powdercoat are more dependent on the type and quality of the materials used than on the two

processes themselves.

But there are disadvantages, and one is color: There are far fewer color choices available in powdercoat than there are with spray paint. And metallic color formulations sometimes create problems with the electrostatic process used to apply the powder.

Another is gloss: It’s much harder-and often impossible-to obtain the same kind of show-bike shine with powdercoating than it is with paint. Due to the rather large particle size of powdercoat materials, the smoothest surface finish is achieved with a thick coat-which might not be suitable for all components, partic-

ularly those that have to fit together snugly or flex ever so slightly. Thinner applications of powdercoat, however, tend to have an orange-peel finish. So to get the smoothest result, the person applying the powdercoat must pay close attention and monitor the process carefully; even then, the outcome usually cannot equal spray painting for sheer gloss.

There’s also a heat factor. Once the powder is electrostatically applied, the part has to be baked in an oven at a temperature in the neighborhood of 400 degrees Fahrenheit, and some components can’t endure that kind of heat. What’s more, touch-up is, at best, more difficult than with paint and impossible at worst. Often, the only course of action is to completely strip the paint-damaged part and powdercoat it all over again.

If there are any “keys” to obtaining top-quality powdercoat work, they are simply to have it done by an outfit with a proven track record. If a powdercoater specializes in industrial work where smoothness and shine are not top priorities, you probably won’t get the glossy result you’re after. But if the shop routinely does work for custom bike and car builders and restorers, your chances of getting an attractive finish are very good.

Honda in hibernation

Q I read your suggestions about cold storage of the Yamaha FJR1300 and Kawasaki Concours 14 ("Arctic sport-touring," August issue). I have a 2006 Honda Interceptor that I store during the Michigan winters and have followed all the suggestions you gave the other reader (tires fully inflat ed, fuel additive, trickle charge). After storage, I do not pull the plugs for the reasons you stated regarding the diffi culty of accessing them, but I was curi ous: Would cycling the motor with the kill switch off be beneficial or just cre ate another problem? Dave Kuehnle St. Helen, Michigan

A Turning the motor over with the electric starter while the kill switch is off is a good idea, particularly with a fuel-injected bike. This circulates oil with the engine at low-load, sub-idle rpm, moves the piston rings to different locations on the cylinder walls and re lieves the tension on any valve springs that were compressed when the engine was shut down, shifting that tension to another valve or two. It does all this with out the engine ingesting any gasoline that could wash lubrication off the cylinder

walls, as the fuel-injection system is inoperative when the switch is off.

The problem is that Hondas are one of the very few brands of motorcycles that allow you to turn the motor over electrically when the kill switch is in the Off position; the starters on the majority of other bikes don’t function unless that switch is on. □

View Full Issue

View Full Issue