TDC

Rubber Revolution

Kevin Cameron

ALTHOUGH WE ALL LOVE ENGINES AND the beautiful parts that whirl unseen within, it is in fact tire technology that has done the most to give the modern motorcycle its outstanding performance. For this reason, any further advance in the tire art is cause to rejoice.

The current advance is an ongoing revolution in tire manufacturing, a process that Pirelli-Metzeler calls “MIRS” (Modular Integrated Robotized System). Its adoption-now in progress-will offer many benefits. Among these are reduced tire weight, cooler operation and the potential for increased grip.

In traditional tire manufacturing, the tire is assembled from sheets of ply fabric and rubber, plus bead-wire bundles, applied in sequence to a tirebuilding drum-often by a human operator. The cylindrical beginnings of a tire are then deformed into rough tire shape, the under-tread belt is applied, and finally the tread rubber strip is laid on and rolled into place. This “green” tire is then placed in a steam-heated mold where high temperature (around 315 degrees F) chemically transforms, or cures, the rubber into an elastic solid. The inflation of an interior bladder both drives the tire out against the inside of the mold and serves to tension the fabric plies.

I was invited by Pirelli-Metzeler to Italy and Germany to see the new MIRS process in detail-a surprising offer in this usually secretive industry. What the new process promises is a way to flexibly produce a variety of tires without the need of large and expensive dedicated facilities. Because materials are better controlled during assembly, MIRS tires have very low out-of-roundness, force variation and out-of-balance. With materials under such improved control, it takes less rubber to guarantee that all parts of the tire are on design spec. The benefits of this are obvious-the less flexing material there is in a tire, the less heat it generates. Because of this cooler running, a softer tread compound can safely generate more grip, or the benefit can be applied to extend tire life. A thinner tire generates a larger footprint, further increasing grip.

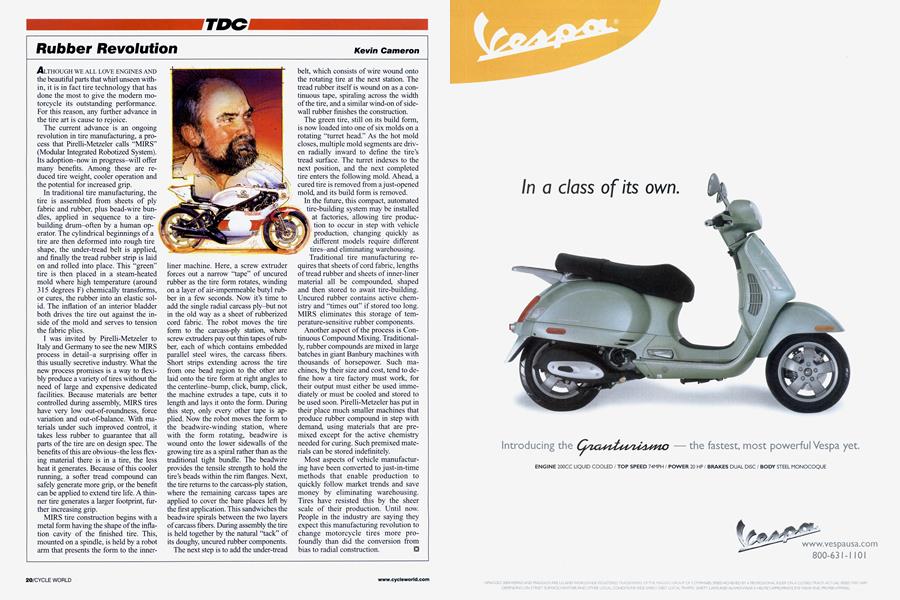

MIRS tire construction begins with a metal form having the shape of the inflation cavity of the finished tire. This, mounted on a spindle, is held by a robot arm that presents the form to the innerliner machine. Here, a screw extruder forces out a narrow “tape” of uncured rubber as the tire form rotates, winding on a layer of air-impermeable butyl rubber in a few seconds. Now it’s time to add the single radial carcass ply-but not in the old way as a sheet of rubberized cord fabric. The robot moves the tire form to the carcass-ply station, where screw extruders pay out thin tapes of rubber, each of which contains embedded parallel steel wires, the carcass fibers. Short strips extending across the tire from one bead region to the other are laid onto the tire form at right angles to the centerline-bump, click, bump, click, the machine extrudes a tape, cuts it to length and lays it onto the form. During this step, only every other tape is applied. Now the robot moves the form to the beadwire-winding station, where with the form rotating, beadwire is wound onto the lower sidewalls of the growing tire as a spiral rather than as the traditional tight bundle. The beadwire provides the tensile strength to hold the tire’s beads within the rim flanges. Next, the tire returns to the carcass-ply station, where the remaining carcass tapes are applied to cover the bare places left by the first application. This sandwiches the beadwire spirals between the two layers of carcass fibers. During assembly the tire is held together by the natural “tack” of its doughy, uncured rubber components.

The next step is to add the under-tread belt, which consists of wire wound onto the rotating tire at the next station. The tread rubber itself is wound on as a continuous tape, spiraling across the width of the tire, and a similar wind-on of sidewall rubber finishes the construction.

The green tire, still on its build form, is now loaded into one of six molds on a rotating “turret head.” As the hot mold closes, multiple mold segments are driven radially inward to define the tire’s tread surface. The turret indexes to the next position, and the next completed tire enters the following mold. Ahead, a cured tire is removed from a just-opened mold, and its build form is removed.

In the future, this compact, automated tire-building system may be installed at factories, allowing tire production to occur in step with vehicle production, changing quickly as different models require different tires-and eliminating warehousing. Traditional tire manufacturing requires that sheets of cord fabric, lengths of tread rubber and sheets of inner-liner material all be compounded, shaped and then stored to await tire-building. Uncured rubber contains active chemistry and “times out” if stored too long. MIRS eliminates this storage of temperature-sensitive rubber components.

Another aspect of the process is Continuous Compound Mixing. Traditionally, rubber compounds are mixed in large batches in giant Banbury machines with thousands of horsepower. Such machines, by their size and cost, tend to define how a tire factory must work, for their output must either be used immediately or must be cooled and stored to be used soon. Pirelli-Metzeler has put in their place much smaller machines that produce rubber compound in step with demand, using materials that are premixed except for the active chemistry needed for curing. Such premixed materials can be stored indefinitely.

Most aspects of vehicle manufacturing have been converted to just-in-time methods that enable production to quickly follow market trends and save money by eliminating warehousing. Tires have resisted this by the sheer scale of their production. Until now. People in the industry are saying they expect this manufacturing revolution to change motorcycle tires more profoundly than did the conversion from bias to radial construction. □