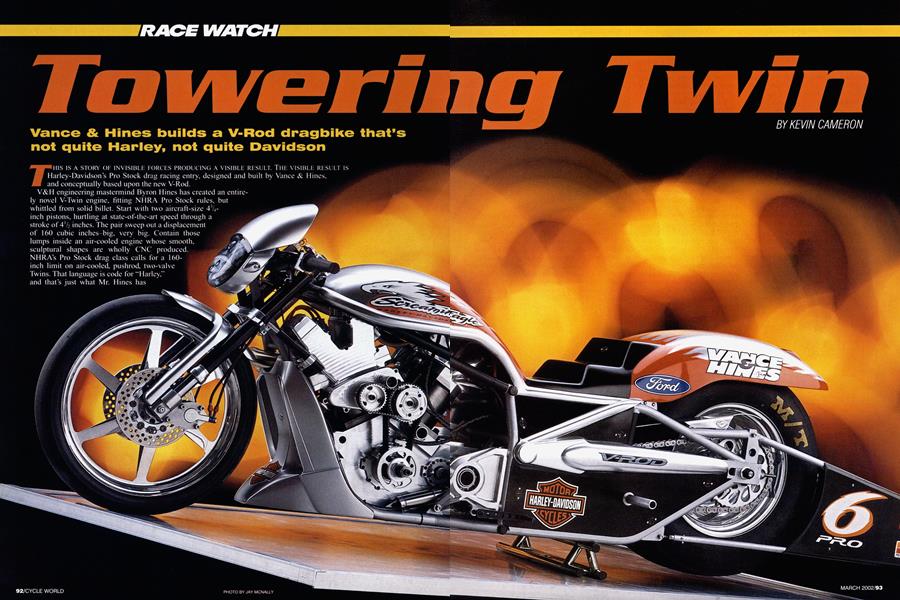

Towerin Twin

RACE WATCH

Vance & Hines builds a V-Rod dragbike that’s not quite Harley, not quite Davidson

THIS IS A STORY OF INVISIBLE FORCES PRODUCING A VISIBLE RESULT. THE VISIBLE RESULT IS Harley-Davidson's Pro Stock drag racing entry. designed and built by Vance & Hines. and conceptually based upon the new V-Rod.

V&H engineering mastermind Byron Hines has created an entirely novel V-Twin engine, fitting NHRA Pro Stock rules, but whittled from solid billet. Start with two aircraft-size 4¾inch pistons, hurtling at state-of-the-art speed through a stroke of 4½ inches. The pair sweep out a displacement of 160 cubic inches-big, very big. Contain those lumps inside an air-cooled engine whose smooth, sculptural shapes are wholly CNC produced.

NHRA’s Pro Stock drag class calls for a 160-inch limit on air-cooled, pushrod. two-valve Twins. That language is code for “Harley." and that’s just what Mr. Hines has built with Harley’s money.

KEVIN CAMERON

Now, do the math-8500 rpm, 160 inches, and an attainable stroke-averaged combustion pressure of 200 psi equal 340 horsepower. A Harley has never qualified for Pro Stock before, but here are 340 reasons for that to change.

Wait a minute: The street-going VRod’s engine is a liquid-cooled fourvalve with overhead cams, and if you bored it to 43/4 inches you’d have nothing left but metal chips. Where does this V&H monster come from? Straight from the rulebook, which requires little more than a family resemblance between parent engine and quarter-mile offspring. That’s what we have here: The Stocker’s engine is a V-Twin, its cylinder angle is 60 degrees, and it’s fuel-injected. All these essential elements are faithfully reproduced in Byron Hines’ towering Twin-together with obvious visual cues taken from the stock motorcycle.

When German company MercedesBenz wanted to win the Indianapolis 500, it commissioned a pushrod engine from Ilmor in England. If an Ilmor is a Benz, Hines’ Twin is a V-Rod. Or consider NASCAR, in which the letters “SC” stand for Stock Car. In its rules, front-drive four-banger unit-body shells are fitted over rear-drive tubular spaceframes, driven by V-Eights that never saw a production line. In racing, “stock” is whatever the rules say it is.

Now for the invisible forces that created this program. The V-Rod is Harley’s play for the interest of younger riders, and it’s a gamble. Honda and Yamaha, unable to top Harley’s lock on style, turned to their own strongest suithorsepower-bidding to switch the play from styling to power-cruisers such as the VTX and Road Star Warrior. Harley has come right back at them with the VRod’s 1130cc of four-valve, liquidcooled and fuel-injected V-Twin. It’s called business competition. Then, Milwaukee raised the bid by announcing it would see whose power was real-in Pro Stock drag racing. Guess where the money from the canceled VR roadrace program went. Right here.

Byron Hines said, “I’d been saying for some time that I thought the right kind of Twin could do the job (in Pro Stock). Now. they’ve sort of called me on it, so I have to produce.”

The opportunity he saw in NHRA’s Pro Stock weight and displacement breaks for air-cooled pushrod two-valve engines was too good to ignore.

Harley’s interest made it possible to afford the necessary five-axis machining centers needed to make the engine Hines envisioned. Byron’s partner, Terry Vance, wanted the project for the obvious and correct external reason-it swings open a door into the vast Harley aftermarket. No one spends money like Harley own ers, and whosoever maketh Harleys competitive against the invading “riceburners” shall find eternal income.

There are other giant Harley drag motors, and they, like Byron’s cleansheet Twin, contain no Harley parts. Cases, cylinders, heads, pistons and rods all come from the intensely creative aftermarket. Hines had something entirely different in mind-something that would fix the chronic problems of lookalike Big Twin drag engines. The biggest difficulty was the long pushrods, extending upward at angles from the tappets in the crankcase to the rockers far above. The more valve lift you give such an engine, the more its rockers rock, and the more sideways motion they impose on the long, twanging pushrods. To make it worse, the lofty and slender cylinders themselves weave around. The result of these cyclic disturbing forces-at best-is erratic valve action and premature valve float. At worst, the pushrods “sproing” right out of their sockets. As one long-ago engine builder once remarked, “Now you need pushrods by the quiverÍ ful.” To keep those “arrows” in . | place, you cut way back on ^

rpm and valve lift, thereby making your eng i nc no mailer how big-inch it may be-uncompetitive.

Having to produce where no one else ever has could give any man the jitters, but the opportunity to start from scratch with his own design must be the purest pleasure for Byron Hines. Not only docs, he have a lifetime of drag racejdesign and dyno experience, but he has worked with factory roadrace engines from Suzuki, Yamaha and Ducati. This means the man knows what it takes, from the outset, to make engines go. “To have the kind of ports it would take to make power, the heads need to be very tall, with the rockers way up high,” Hines says. “That meant if the cams were down in the case, the pushrods would be so long that it couldn’t work.”

So, the cams had to go up to shorten the pushrods to a manageable length, just as was done in the classic Vincent V-Twin. Hines’ solution was to put the stubby cams in triangular boxes that attach to the undersides of the heads. The followers would be long levers with rollers to bear on the cam lobes and sockets for the pushrods. Each camand-lever box carries its own sealed, 3ounce oil supply, which pumps itself up the hollow pushrods to the rockers. This system does away with another dreaded Harley problem-casc-pumping that traps oil in the heads. A toothed belt drives a half-time shaft in the cylinder Vee, and other toothed belts carry the drive from this shaft to the cams. To make front and rear cylinders the same, the cambox is on the left of the front cylinder, and the right side of the rear one. Intakes are in the Vee. At the tops of the approximately 7-inch pushrods are long, high-leverage rocker arms to operate two valves per cylinder.

And what valves these are-made of titanium to cut their mass by 40 percent. Intakes are 2'/2 inches in diameter (63.5mm), with long, slender stems that allow the ports to be pulled up at steep downdraft angles. Hines opened the throttles to let me look straight down to the valves. Exhausts are 2 V8-inch across, and their flat-bottomed ports are pulled up, too, straightening the shot to increase flow. The only other racebike engine with upflow exhausts like these is Ducati’s new Testastretta 998 Twin. Valve stems are protected by steel lash caps, against which bear the roller rocker tips.

Hines explained that the current trend in high-rpm pushrod engines is to limit the motion at the cam, and then get the desired lift from a higher rocker-arm ratio. A typical rocker ratio for a traditional American V-Eight engine is The V&H-Rod’s valves move twice as far as its pushrods. Valve lift is .945inch, or 24mm-two or three times more than in typical streetbikes.

All the porting is done by CNC, but because the exterior of the engine is likewise CNC-finished, it is as though the supernatural ly smooth port shapes spread outward until they covered the whole machine. These parts look as if they were carved by thousands of smooth, parallel fingernail traces. What you are seeing is the tool paths called out by the CNC software. The 38-pound crankcase started life as a 275-pound aluminum billet, and the ball-bearing crankshaft-looking much like that of a Ducati 996 but larger-began as a 175pound chunk of 4340 steel. There is a single crankpin, lubed 360 degrees by an oil-transfer bushing, with the plainbearing con-rods side-by-side. The engine has steel rods now, but Jet Titanium replacements are coming. Hines said the initial roughing cuts, as aluminum machining began, were really impressivean intense snowstorm of hot chips.

“There’s only one gasket in the whole engine,” he noted with audible pride, indicating a selective-thickness rubbercoated item that joins each cam-and-lever box to the underside of its head. The cylinder heads are sealed by copper rings, bearing against mating raised areas, located by four dowel pins. The cylin-

ders are massive flanged pieces of cast iron. All other mating surfaces are sealed in civilized fashion by Viton Orings in contour-cut grooves. All that silly 19th-century gasket-and-sealer nonsense is banished.

The cylinder heads are the most beautiful CNC parts I have ever seen, smoothly contoured and gleaming on every exterior surface. There are no cooling fins because all the cooling occurs after each run, with pit fans blowing on the engine. The valve towers and rocker boxes grow organically upward out of the head itself, with a narrow 40degrce angle between the two valves. Each head carries two 10mm sparkplugs, and the chambers themselves are polyspherical, with a central pocket flanked by lateral squish areas. To be compatible with easily damaged titanium valves yet hard enough to maintain valve clearance, the seats are of silicon bronze. The shallow combustion chambers achieve the desired 16.2:1 compression ratio with essentially flat-topped pistons. Why so much compression? Drag engines must “turn the tire,” and to leap through that all-important first 60 feet all possible torque is required. Knock? Detonation is heat-driven, and drag engines come to the line cold.

When I saw it, the bike was being run for a TV crew, so the runs were “soft.” Nevertheless, run after run, the engine performed flawlessly-the only trouble being a need for more spring pressure in the clutch (rpm was too low to make the centrifugal lockup mechanism effective). Peak torque from this engine is likely to be close to 250 foot-pounds, and with the 1.44 primary ratio (these narrow, straight-cut gears are designed to handle 450 bhp) this becomes a hefty 360 ft-lbs. at the clutch itself.

The engine starts easily with an external starter, and has a rough, muscular idle. It sounds like a big, BIG Superbike V-Twin. Being more than 2'/2 times larger, it should. The first action was a series of for-the-camera burnouts, begun in water. Matt Hines, on hand to ride for the cameras, paddled slowly forward, rear tire smoking, engine growling steadily. That same growl accompanied the runs to top gear, the engine easily keeping the tire working throughout.

This bike has a five-speed V&H semi-automatic transmission of the type that eliminates all power loss during upshifts. As the next-higher gear is engaged by the shift fork, and that gear begins to drive, the previous gear-still engaged-rotates backward. This causes its dogs to encounter ramps cut in the non-thrust sides of the mating gear’s dog set. This kicks the previous gear out of engagement. Because of these kick-out ramps on the first four gears, the rider cannot close the throttle until top gear is engaged. To the rider, semi-auto upshifts are, Byron noted, “Smooth as glass.”

He showed me a pair of these transmissions, one a five-speed, the other a six. The pointy, coarsc-pitch straightcut gear teeth have a high-pressure angle to increase their bending strength, and are, like the crankshaft, made ofO 4340 steel. Why not a surface-hardening gear steel, as in production bikes?

“Wear’s not the problem here,” Hines said. “Strength is.”

The bike has its engine far, far forward-so much so that mechanics can easily pick up the rear by the wheelie bar and trundle it away like a CNC wheelbarrow. This is testimony to the grip of that 10-inch-wide slick—that it can exert a thrust great enough to overcome the leverage of the far-forward engine and rider right off the line, riding (lightly) on the wheelie bar with the front end just off the track.

The fuel tank is carried in a chin fairing just behind the narrow aluminum front wheel, and circulates through a line that carries it past the two Holley Commander 950 fuel injectors, one per massive, short intake pipe. Holley supplied an estimated fuel curve in response to Hines’ information.

Rules specify a maximum 70-inch wheelbase and a 580-pound combined machine and rider weight. Acceleration should be good, to put it mildly.

Launch thrust in this class is estimated at 3 to 3V2g’s!

For this photo shoot, the engine was purposely tuned far short of its expected performance. Ignition timing for best torque is forecast to be 30-32 degrees, but in this test was pulled back to 24. Piston-to-head clearance, which will be so close in competition that it makes “light spots,” was a generous .075-inch. Fuel mixture was still rich, and it sounded rich, especially down low. Peak revs are supposed to be in the range of 8500-9000 rpm, which with the 4’/2-inch stroke will result in colossal piston speeds of up to 6500 feet per minute. Don’t worry about it: Hemi Chrysler drag engines have lived up there for 30 years now. This engine only has to do it for 7 seconds at a time.

This motorcycle is beautiful and Harley-Davidson is obviously spending the budget necessary to do this racing effort right. But behind all this is the interesting note that no Harley has ever qualified in Pro Stock drag racing. On the other hand, V&H has never failed to qualify in the class since its beginning in 1977. This is a gamble of classic dimension. Place your bets.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

Up FrontCollecting Made Easy

March 2002 By David Edwards -

Leanings

LeaningsThe 11th-Hour St1100

March 2002 By Peter Egan -

TDC

TDCKnock, Knock...

March 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

March 2002 -

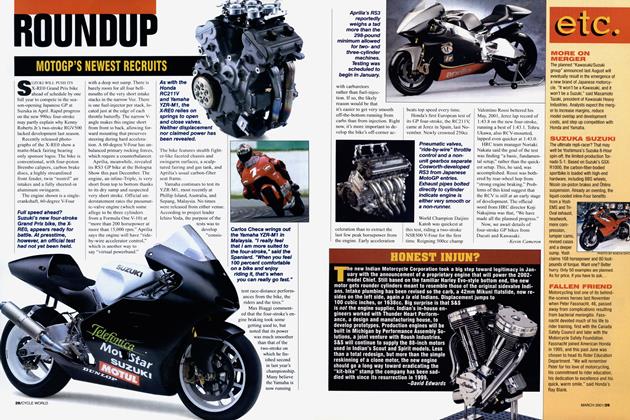

Roundup

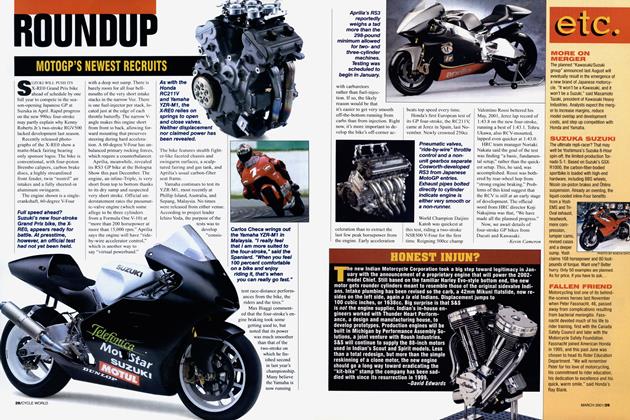

RoundupMotogp's Newest Recruits

March 2002 By Kevin Cameron -

Roundup

RoundupHonest Injun?

March 2002 By David Edwards