SERVICE

Paul Dean

The angle of the dangle

I just bought a 2003 Honda VTX 1300R, and since the bike has no centerstand, I would like to simplify the task of checking the oil and coolant levels. Following the procedure described in the manual, I now have to balance the bike in an up-right position and then try to reach back and pull out the dipstick to check the oil. My idea instead is to check it in this way just once, then, knowing that the oil level is correct, put the bike on its sidestand and score the dipstick at the level it shows in that position. Thereafter, I could always check the oil on the side-stand. Fd like to do something similar with the engine coolant by verifying the correct level with the bike held upright, then leaning it over on the sidestand and marking that level with a magic marker. Can you think of any reason that my idea would not work? Why don’t the manufacturers do this for bikes that are not equipped with centerstands? Terry Flanagan Trumbull, Connecticut

Actually, some manufacturers do recommend checking the oil with the bike on its sidestand, depending on the model. Certain Harley-Davidsons, for instance, are required to have their oil checked when parked on the sidestand, while other H-D models need to be in a perfectly upright position. The difference has to do with the shape of the oil reservoir and the location of its dipstick. If the reservoir is symmetrical from left to right, and if the dipstick enters the oil at the exact sideto-side midpoint of the reservoir, the reading on the dipstick will be the same no matter if the bike is upright or leaned over on its sidestand. But if the reservoir and dipstick do not meet those requirements, the measured oil level will vary as the bike s angle changes.

Your VTX has neither a symmetrical oil tank nor a center-mounted dipstick, so your suggested method would produce inconsistent oil-level readings. If you were to check the oil on a sloped surface next to the pumps at a gas station, on an angled driveway or on any less-than-horizontal surface, the readings would vary. If your bike ’s sidestand were to bend a little over time or develop extra freeplay in its pivot mechanism, the readings would vary. If the bike’s fork or shock springs sagged over time, the readings could vary. So, unless you carried an inclinometer along with you on all your rides, you would never know if the bike were parked at the same angle as it was when you made the score mark on the dipstick.

But vertical is always vertical, no matter the angle of the surface on which the bike is sitting. If you balance the bike in a perfectly vertical position, the oil-level readings will always be consistent. Some owner’s manuals for bikes that do have centerstands even caution against checking the oil on the stand if the surface on which the bike is parked isn’t flat and level. They prescribe taking the bike off the centerstand and checking the oil while balancing the machine upright on its wheels-just as you now must do with your VTX1300.

Crank it up

I have a technical question about crankshaft design. Fve read that some three-cylinder engines have 120-degree cranks, such as BMW K75s, Triumph Tridents, BSA Rocket 3s and Yamaha XS Triples, while others have 180-degree (flat) cranks, such as Laverda Triples. I’ve also read that inline-Twins can be built with 360-degree cranks that make the pistons go up-anddown together, or with 180-degree cranks that make them go up-and-down alternately. I can’t figure out how it is possible for an engine to have even ignition intervals if a Triple has a flat crank or a Twin’s pistons don’t go up-and-down at the same time. Can you explain? Klaus Zelm Bang Saphan, Thailand

This one s easy, Klaus: They in fact do not have equally spaced ignition intervals. A four-stroke engine requires 720 degrees of crankshaft rotation for every cylinder to fire, so a three-cylinder four-stroke with a 120-degree crankshaft fires evenly, once every 240 degrees. And on a parallelTwin with a 360-degree crank, the firing intervals also are even, occurring every 360 degrees. But on a Triple with a 180degree crank, the cylinders fire at 180360-180-degree intervals; and a Twin with a 180-degree crank has its firing cycles phased at 540-180 degrees.

Uneven firing intervals are not problematic. After all, the most enduring and endearing engine configuration in the history of motorcycling-the VTwin-has survived a century of firing at uneven intervals. Indeed, that unequal sequence is what gives Harley-Davidson engines their beloved “potato-potato ’’ exhaust cadence.

Slip slidin’ away

My query relates to the adhesion of tires on the road surface: Does asphalt or concrete provide better grip when cornering? Some states have concrete on/off freeway ramps, while other states seem to prefer asphalt ramps. I’m always concerned when in a hard cornering situation that my hot and sticky tires won’t grip a concrete ramp as well as an asphalt one. Mark B. Thompson, EOC U.S. Navy SEABEES

There is no indisputable answer to that question. In and of itself concrete generally has a slightly higher coefficient of friction than asphalt; but the amount of traction any given tire might have on any given road surface is dependent upon many factors besides the material of which that surface is made. Variables such as the texture of the surface, the age of the surface, the wear and tear of the surface, the presence of foreign materials on the surface, the temperature of the surface, the absence or presence of bumps and irregularities on the surface, all determine how much grip is available. As a result, the type of material used on a roadway serves as neither a red light nor a green light for hard cornering on a motorcycle; the condition of the surface and what is on it is far more important than what it is made of.

FEEDBACK LOOP

In the September issue, you answered a question about a gasoline overflow situation (“Float follies ) supposedly caused by the floats. I have had the same overflow problem on two different bikes. The floats were adjusted correctly and the needle and seat were perfect, yet gas still overflowed. The problem turned out to be the O-ring that seals around each seat assembly where it pushes into the carb body. The O-rings had deteriorated, causing them to harden and crack, which allowed gas to seep past and overflow from the float bowls. This problem occurred even though the needle tip was pushed into the seat as designed. Your reader does not say what model carbs he has, but his problem could be the result of these O-rings. My carbs were VM26SS Mikunis on an ’84 Yamaha RZV500 and, more recently, CVK40 Keihins on my ’98 Kawasaki ZX-9R. My suggestion is never to leave gas in the carbs when storing a bike. It eats up these O-rings, which get hard, crack and then leak.

The second problem is getting replacement O-rings. They’re very thin, metric-sized and usually aren’t available separately from the needle-and-seat assemblies. Hardware-store replacements don’t fit; they’re all too thick. Sudco has O-rings for Keihin FOR carbs that also fit CVK40s. They cost $1.50 each, which is much better than $52 for a needle/seat assembly from Kawasaki. There may be other sources, as well.

Paul Frisch Lake Forest, Illinois

Great tip, Paul, although I doubt that it applies to the problem encountered by David Maness, who submitted that inquiry. He reported that during his diagnostic procedure, which involved raising the floats by hand with the fuel lines connected, there was no fuel seepage whatsoever. If the O-rings on the float-needle seats had been leaking, he would have observed fuel dribbling past them. But thank you for the tip nonetheless. It’s a very insightful piece of information that could prove invaluable to anyone who is trying to diagnose a float-bowl overflow problem.

What I find curious, though, is your repeated reference to freeway onand offramps but not even the slightest mention of bacbvad corners. If you spend much of your riding time charging hard around freeway ramps, it doesn’t matter what material was used in the road surface; you are destined to fall down. Freeway ramps are among the dirtiest, slimiest, slipperiest pieces of public road you could possibly find, with many of them offering absolutely no run-off whatsoever. My advice is not to worry about the paving material; worry instead about what is on the pavement, and ride onto and off of freeways with intelligence, not aggression.

Electra-cal gremlins

I have a 1990 Harley-Davidson FLHTC Electra Glide Classic that dies while moving. I usually warm the engine up for a couple of minutes, and after I take off, the bike just quits running. The lights go out, there’s no voltage registered on the meter, no oil pressure on the gauge; it just dies as though I had turned it off, even though the ignition switch is still on. Then, after I roll to the side of the road with the ignition on, the gauges start working and I can start the engine again.

Techtips

Anyone with motorcycles who has ever and tinkered cars is familiar with snap rings, those circlets of spring steel that hold or locate all sorts of key components-transmission gears, oil-pump shafts, fork dampers, clutch hubs and countless other important parts and pieces. But most people, even quite a few experienced mechanics, aren’t aware that these simple retaining devices are directional. Snap rings are manufactured by an automated press that stamps large quantities of them out of sheet steel. As a result of that stamping process, one side of the ring (the side contacted first by the stamping die) has a slightly rounded edge, while the other side has a perfectly sharp edge. You can easily detect this difference by looking at a snap ring very closely, or by rubbing your thumb across both of its edges; the sharp edge feels almost knifelike and the rounded edge, by comparison, feels dull.

When properly installed, a snap ring should be oriented with its sharp edge facing in the direction of thrust; this is of particular importance when the groove in which it sits is rather shallow. If the snap ring faces the wrong way, its rounded edge can serve as a “ramp” that allows side thrust to compress the ring enough to jump up out of its groove. If the ring faces in the proper direction, however, even large amounts of side thrust will not cause it to compress and depart the groove.

-Paul Dean

Recall Roster

NHTSA Recalls No. 02V190 & 02V191 BMW F650CS Model year: 2003 Number of units involved: 577 Dates of Manufacture: January to May, 2002 Problem 1 : The drive-belt pulley on the rear wheel could possibly develop a crack that, over time, could cause the pulley to fail and the drive belt to derail. Problem 2: The nut that secures the front drive-belt pulley to the transmission output shaft could loosen, resulting in damage to the splines on both the pulley and the shaft. Remedy: Dealers will replace the rear-wheel pulley, and will check the torque on the front-pulley nut and, if necessary, tighten it and secure it with LocTite. Owners who do not receive this free remedy within a reasonable time should contact BMW at 800/831-1117, Option #4.

Sometimes this problem occurs right away, other times it doesn’t happen until I’ve ridden as far as 50 miles. I’ve checked out all the circuit breakers and they seem okay, and I’ve also put in a new starter relay, but that hasn’t helped. Any assistance you could offer would be greatly appreciated. Bob Galdys Los Altos, California

Your FL either has a bad main circuit breaker or an electrical short somewhere in the main wiring harness. You said that you “checked out all the circuit breakers,” but I don’t know of any conclusive way to do that. H-D circuit breakers are designed to trip if subjected to a current overload, then automatically reset after they cool down, which usually only takes a few minutes. But even the Harley shop manuals do not describe a procedure for testing them.

What’s more, your FL has circuit breakers in two different locations. There are several up under the fairing cap that are wired into the various electrical systems around the bike (lights, ignition, accessories, etc.), and one main 30-amp circuit breaker under the seat. Most likely, that main breaker is kicking off thereby shutting off all power, and it is doing so for either of two reasons: The bimetallic strip inside of it trips prematurely because it has gotten fatigued from age and can no longer handle the normal current draw; or there is a short in the main wiring, somewhere between the battery and the individual system circuit breakers, causing a current overload that trips the breaker.

Before you even attempt to find an electrical short, simply replace the main circuit breaker. They’re cheap and easy to access; and if the power outage does not reoccur after the replacement, you will know for certain that the breaker was the culprit.

If the bike continues to shut down, however, you ’ll then have to undertake a systematic diagnosis of the main wiring harness, including the section that leads down to the alternator. Look for bare, burned or pinched wires, especially in places where the wiring can chafe or be squeezed between two components. Don’t bother checking the wiring in the systems safeguarded by the individual circuit breakers under the fairing cap; if the problem was there, the affected circuit breakers in that system would trip before the main breaker.

Need a lift?

I own a 1999 Honda VT1100 Shadow Aero. I am trying to find a lift that will hold the bike while I work on it, clean it and change its tires. I’m not talking about a ride-on lift; I want to be able to remove the wheels. The only one I’ve seen that would work costs several hundred dollars, which is way too much cash for me to justify. And I don’t like what my local Honda dealer uses; it’s okay for him but not what I’m looking for. Can you help?

Gerald Wilmoth Easton, Maryland

Maybe I can. Sears sells a Craftsman motorcycle/ATV lift, part number 50190, that has a 1500-pound weight capacity and a price of just $119.99. I’ve never used one, but it seems ruggedly built, has four tiedown loops and rubber-padded lift arms. It could be just what the home-garage doctor ordered. □

Got a mechanical or technical problem with your beloved ride? Can’t seem to find reasonable solutions in your area? Maybe we can help. If you think we can, either: 1 ) Mail your inquiry, along with your full name, address and phone number, to Cycle World Service, 1499 Monrovia Ave., Newport Beach, CA 92663; 2) fax it to Paul Dean at 949/631-0651; 3) e-mail it to CW1Dean@aol.com, or 4) log onto www.cycleworld.com and click on the Feedback button. Please, always include your name, city and state of residence. Don’t write a 10page essay, but do include enough information about the problem to permit a rational diagnosis. And please understand that due to the enormous volume of inquiries we receive, we can’t guarantee a reply to every question.

View Full Issue

View Full Issue

More From This Issue

-

Up Front

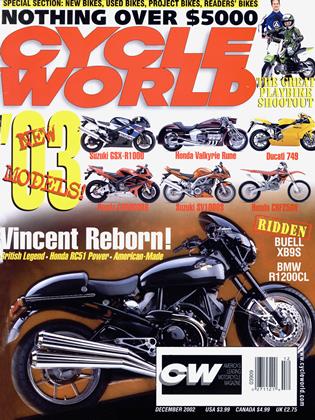

Up FrontBeginner's Luck

December 2002 By David Edwards -

Leanings

LeaningsThe Thousand Mile Ride

December 2002 By Peter Egan -

TDC

TDCFlexi-Flyers

December 2002 By Kevin Cameron -

Departments

DepartmentsHotshots

December 2002 -

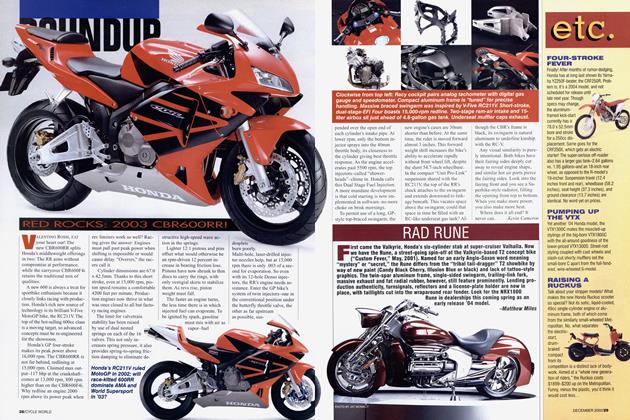

Roundup

RoundupRed Rocks: 2003 Cbr600rr!

December 2002 By Kevin Cameron -

Roundup

RoundupRad Rume

December 2002 By Matthew Miles