SERVICE

Paul Dean

Snip, don't slip

I have a ’93 Harley-Davidson Dyna Wide Glide that I want to liven up a bit, and I plan to do all the modifications myself-carb, air cleaner, exhaust system and cam. None of this work intimidates me, but my buddies all say that in order to install the cam, I’ll have to remove the heads just so I can get the pushrods in and out. Is this true, or is there some “secret” tip they don’t know about?

Harley (my real name, honest) Erstadt Omaha, Nebraska

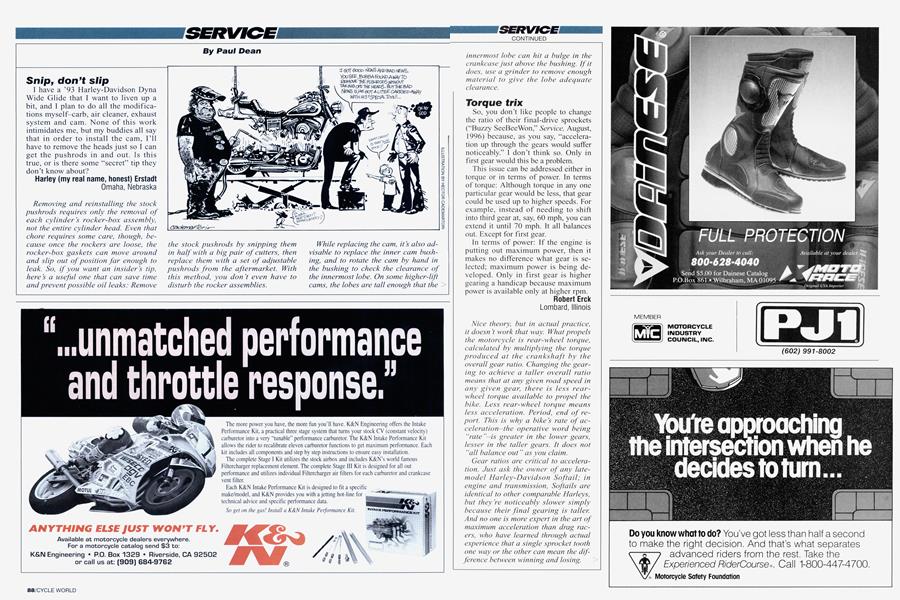

Removing and reinstalling the stock pushrods requires only the removal of each cylinder’s rocker-box assembly, not the entire cylinder head. Even that chore requires some care, though, because once the rockers are loose, the rocker-box gaskets can move around and slip out of position far enough to leak. So, if you want an insider ’s tip, here’s a useful one that can save time and prevent possible oil leaks: Remove

the stock pushrods by snipping them in half with a big pair of cutters, then replace them with a set of adjustable pushrods from the aftermarket. With this method, you don’t even have to disturb the rocker assemblies.

While replacing the cam, it ’s also advisable to replace the inner cam bushing, and to rotate the cam by hand in the bushing to check the clearance of the innermost lobe. On some higher-lift cams, the lobes are tall enough that the innermost lobe can hit a bulge in the crankcase just above the bushing. If it does, use a grinder to remove enough material to give the lobe adequate clearance.

Torque trix

So, you don’t like people to change the ratio of their final-drive sprockets (“Buzzy SeeBeeWon,” Service, August, 1996) because, as you say, “acceleration up through the gears would suffer noticeably.” I don’t think so. Only in first gear would this be a problem.

This issue can be addressed either in torque or in terms of power. In terms of torque: Although torque in any one particular gear would be less, that gear could be used up to higher speeds. For example, instead of needing to shift into third gear at, say, 60 mph, you can extend it until 70 mph. It all balances out. Except for first gear.

In terms of power: If the engine is putting out maximum power, then it makes no difference what gear is selected; maximum power is being developed. Only in first gear is higher gearing a handicap because maximum power is available only at higher rpm.

Robert Erck Lombard, Illinois

Nice theory, but in actual practice, it doesn’t work that way. What propels the motorcycle is rear-wheel torque, calculated by multiplying the torque produced at the crankshaft by the overall gear ratio. Changing the gearing to achieve a taller overall ratio means that at any given road speed in any given gear, there is less rearwheel torque available to propel the bike. Less rear-wheel torque means less acceleration. Period, end of report. This is why a bike’s rate of acceleration-the operative word being “rate”—is greater in the lower gears, lesser in the taller gears. It does not “all balance out” as you claim.

Gear ratios are critical to acceleration. Just ask the owner of any latemodel Harley-Davidson Softail; in engine and transmission, Softails are identical to other comparable Harleys, but they ’re noticeably slower simply because their final gearing is taller. And no one is more expert in the art of maximum acceleration than drag racers, who have learned through actual experience that a single sprocket tooth one way or the other can mean the difference between winning and losing.

Wallow to the min

In regard to “Wallowing to the Max” in your October Service, I’m a proud owner of a 1985 V-Max who also experienced wallowing problems like those described by Mr. Kohler. That is, until I joined Dale Walker’s V-Max Club and ordered a front-fork brace from the club’s catalog. This brace is much thicker than the original one and works wonders for the handling. I urge fellow V-Max owners to acquire this catalog to find high-performance and handling parts specifically designed for this fun, fast and unique motorcycle.

Milton M. Verger Lehighton, Pennsylvania

Thanks for the tip. Judging by the volume of mail I get on this subject, a lot of V-Max owners will appreciate your suggestion.

Cranky cranker

I recently purchased an ’82 Yamaha 750 Virago. The starter sounds like the average Virago’s (large marbles loose inside), and I want to fix it. Years ago, you wrote of a permanent fix for clunky Virago starters; but since I did not own or plan to own a Virago at that time, I did not keep that issue. Can you tell me which issue this was in? Matthew O’Conner

Seattle, Washington

That response appeared in the September, 1992, issue, but the information it contained is out of date. I still get quite a few letters about Virago starter problems, however, so an update is in order.

First, the problem: Virago starters use a planetarv-type gear assembly in which a small plate must resist rotation against the torque of the starter. The plate is held in place only by friction, so it sometimes works loose and turns when the starter is engaged. The result is little or no torque delivered to the starter’s output shaft, usually accompanied by a loud grinding noise.

Then there’s the solution: Weld the plate to the ring gear. This operation, which requires some special notching and trimming, is a $125 package offered by Midland Motorcycles (104 E. Avenue K4, Unit D, Lancaster, CA 93535; 805/949-6376), and that price includes a complete overhaul of the starter. This is not the same shop listed in the 1992 Service response, but it is operated by the same person.