SERVICE

Paul Dean

Helmet hygiene

What is the best way to clean the inside of a helmet? In particular, I’m interested in getting rid of the bad odors that develop in the interior after a season or two of use. Keith R Nelson Saginaw, Michigan

All major helmet manufacturers recommend the same basic cleaning procedure for non-removable liners. Use only a mild soap, such as Ivory Snow or Woolite, and cool or lukewarm water; never use hot water. Put some soap in a small pan of water and work it up into a good foam, then sponge a generous amount of just the foam-not the water-onto the helmet liner. Work the foam around in a gentle scrubbing motion until any dirt on the liner has been loosened, then sponge off the dirty foam with clean water.

If necessary, repeat this process until the liner is clean. Be liberal with rinse water to make sure all the soap is removed from the liner; otherwise, the

soap residue will become tack}’, causing dirt to stick to the liner more readily.

Once the liner is clean, simply airdry it. If you need to speed up the drying process, place the helmet in front of a fan with the interior facing into

the airstream. Do not dry the liner in the sun, and never use a hair dryer or other heat sources. High temperatures can damage the EPS (Expanded Polystyrene) inner shell and compromise its ability to absorb impacts. Usually, a cleaning of this type will remove all odors from the liner. But if some unpleasant smells remain, use one of the odor-removing products currently on the market, such as Helmet Fresh. These products contain enzymes which “eat ” bacteria that cause odors.

Ninja la-bottomy

I have a 1990 Kawasaki 750 Ninja on which I’ve logged 22,000 miles in five years. In all this time it has had just one problem: a minor leak in the front fork. I took the bike to my dealer to have the fork seals replaced, and when I picked it up, the front end bottomed out before I even left the parking lot. The dealer told me it takes a little time for the fork to build up pressure, so he rode the bike around the parking lot for 15 minutes, but to no avail. He then said the oil they had used was too light, so they changed it to 20-weight. That made the suspension a bit better, but it still bottoms a lot, especially when riding two-up. But I don’t remember the fork ever bottoming before I took the bike in for seal replacement.

According to the owner’s manual, the correct fork oil is SAE 10w20. But Kawasaki USA says this oil is no longer available and suggests using 20-weight as the dealer allegedly did.

Please tell me why I am having this problem. No other dealer around here wants to touch my bike’s fork.

John David Szuch

Throop, Pennsylvania

I suspect your 750 Ninja is bottoming-out too easily for one of two reasons: Either your dealer didn 7 put enough oil in the fork, or he somehow disabled the ESCS (Electric Suspension Control System) anti-dive mechanism on the right fork leg.

First the oil level: On a simple oil change-which involves emptying the fork tubes via the drain holes on each lower leg and refilling them through the top of the tubes-Kawasaki specifies 325cc of 10w20 (or 20-weight) oil in each leg. When the fork is drained that way, however, some oil remains inside. But if the legs are disassembled, as they were when your dealer replaced the seals, all the oil is removed. Refilling them, therefore, requires more oil, a total of 380cc, to be precise. If your dealer is unaware of these different oil levels (and he certainly is way out in left field with his pressure build-up theory), each of your Ninja s fork legs could be 55cc low on oil.

There s an easy way to find out. With the bike on its centerstand, remove the fork caps and carefully withdraw each spring so that any oil on its coils drips back down into the tube. Compress the front end until the fork is completely bottomed, then measure the distance from the top of each fork tube to the surface of the oil. If the oil level is correct, that distance should be between 118 and 122mm on the left tube, and between 147 and 151mm on the right. Obviously, if the level is too low on either side, add the appropriate amount of oil.

This difference in right and left oil levels is caused by the presence of the anti-dive mechanism on the right leg. Both legs take the same amount of oil, but the level ends up being lower on the right because of the added volume of the ESCS housing on that leg.

When the dealer reassembled the fork, he may have forgotten to hook up the anti-dive. You didn ’t mention when or how the front end bottoms; but if it absorbs bumps nicely yet bottoms easily when the front brake is applied, the anti-dive isn 't functioning.

To check it, ensure that the wire between the front-brake lever and the anti-dive unit is connected. If it is, disconnect it and clip a test light between the end of the wire and its terminal on the ESCS. With the ignition on, the test light should illuminate when the front brake lever is squeezed. If it doesn 't, there s an electrical problem, probably with the switch at the front-brake lever.

If no electrical gremlins are found, put the front wheel against a wall, turn the ESCS adjuster to its highest (#3) position and pump the front end up and down while squeezing the front brake lever. Then pump it up and down again without the brake. If you can detect no difference between the frontend action with the brake on and the brake off, the anti-dive is not functioning. If you can’t remedy the problem by cleaning the anti-dive mechanism, you ’ll have to buy an entire replacement unit; Kawasaki does not sell individual parts for the ESCS.

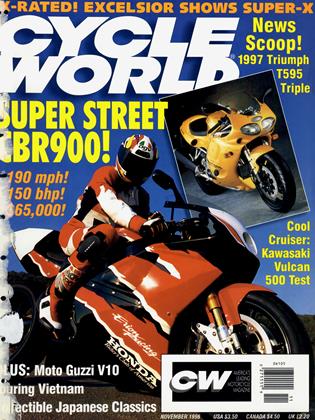

CBRattler

The Honda CBR900RR I bought recently is an absolute pleasure to ride, but I do have one concern. I’ve noticed that when the bike is running toward the cooler end of its operating > range and I crack the throttle wideopen at around 2500 rpm, the engine makes sort of a ticking noise (especially if the transmission is one gear too high) until it gets up to about 4000 rpm; from that point upward, l hear nothing but the smooth exhaust noise. If I open the throttle slowly, the engine doesn’t make this noise, which reminds me of a mild valve tapping. When the engine is nearer the warmer end of its operating range, I either don’t hear the noise at all or it is very subtle. I always use 92 or 93 octane gas, and there is no lack of performance; the engine really screams on top, in fact. The service manager at my shop says this noise is a characteristic of the 900RR. Since I have not ridden other CBRs, I would appreciate your thoughts. Eric Fehrmann Tarpon Springs, Florida

A/though most noises can be practically impossible to diagnose accurately by someone who has never actually heard them. I believe that the tapping you describe is being caused by the carburetor slides. Under certain normal operating conditions, the slides in the 900RR 's four carbs can vibrate back-and-forth slightly in their bores, causing a light rattle. This noise is not the result of illfitting slides, worn-out carb bodies or anything of the sort; as your mechanic has stated, the rattling is a characteristic of CBR900RR.S (and a few other similar high-performance bikes, as well), but it does not adversely affect performance.

On the 900, the carbs are tucked behind and above the inclined cylinder bank, up inside a cutout in the bottom of the fuel tank, w here there is very> little cooling air. This makes the carbs subject to so much engine heat that the carb bodies could possibly distort just enough to make the slides hang up; so, the slides are made with a comparatively loose fit in the carb bodies. Consequently, when certain conditions are just right-such as when the throttle is wide-open, the engine is lugging at lower rpm and the air flowing through the intake tract is pulsing back-andforth at just the right frequency-the throttle slides will rattle audibly.

More heat causes sufficient reduction in slide clearance to virtually eliminate the rattle; and higher engine revs raise the frequency of the intake pulses to a level that does not cause a sympathetic vibration of the slides.

View Full Issue

View Full Issue