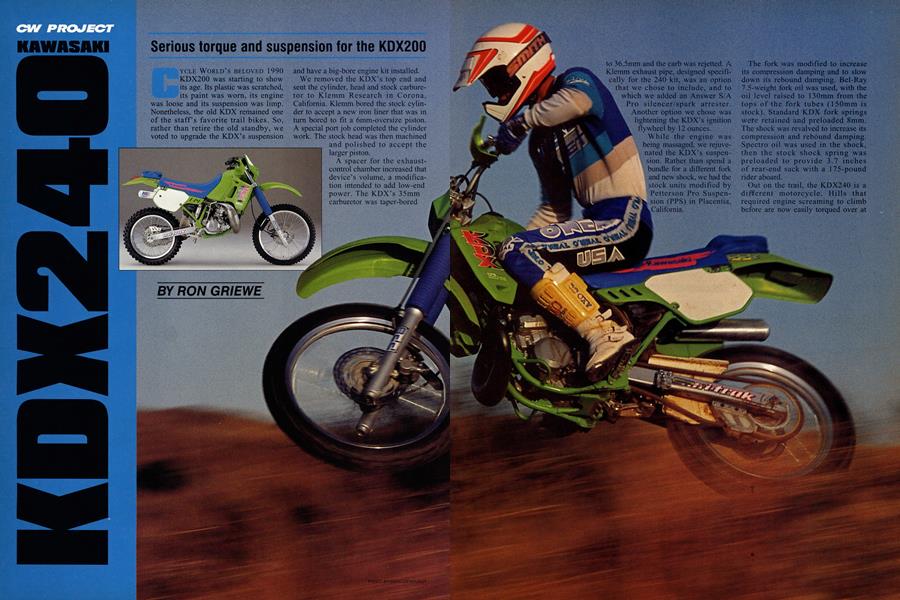

KAWASAKI KDX240

CW PROJECT

Serious torque and suspension for the KDX200

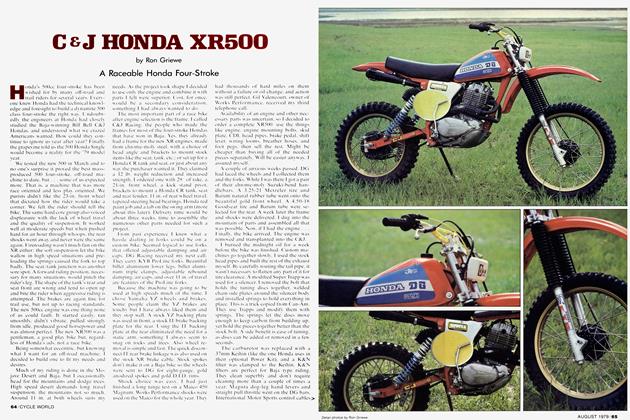

CYCLE WORLD’S BELOVED 1990 KDX200 was starting to show its age. Its plastic was scratched, its paint was worn, its engine was loose and its suspension was limp. Nonetheless, the old KDX remained one of the staff’s favorite trail bikes. So, rather than retire the old standby, we voted to upgrade the KDX’s suspension and have a big-bore engine kit installed.

We removed the KDX’s top end and sent the cylinder, head and stock carburetor to Klemm Research in Corona, California. Klemm bored the stock cylinder to accept a new iron liner that was in turn bored to fit a 6mm-oversize piston. A special port job completed the cylinder work. The stock head was then machined and polished to accept the larger piston.

A spacer for the exhaustcontrol chamber increased that device’s volume, a modification intended to add low-end power. The KDX’s 35mm carburetor was taper-bored to 36.5mm and the carb was rejetted. A Klemm exhaust pipe, designed specifically for the 240 kit, was an option that we chose to include, and to which we added an Answer S/A Pro silencer/spark arrester. Another option we chose was lightening the KDX’s ignition flywheel by 12 ounces. While the engine was being massaged, we rejuvenated the KDX’s suspension. Rather than spend a bundle for a different fork and new shock, we had the stock units modified by Petterson Pro Suspension (PPS) in Placentia, .California.

RON GRIEWE

The fork was modified to increase its compression damping and to slow down its rebound damping. Bel-Ray 7.5-weight fork oil was used, with the oil level raised to 130mm from the tops of the fork tubes (150mm is stock). Standard KDX fork springs were retained and preloaded 8mm. The shock was revalved to increase its compression and rebound damping. Spectro oil was used in the shock, then the stock shock spring was preloaded to provide 3.7 inches of rear-end sack with a 175-pound rider aboard.

Out on the trail, the KDX240 is a different motorcycle. Hills that required engine screaming to climb before are now easily torqued over at half throttle. The 240 engine pulls strongly from just off idle and continues pulling into a great midrange peak. The engine will rev if the rider insists, but there’s not much power being produced in the engine’s upper rev zone. Short-shifting to keep the engine in the fat part of its powerband is the way to go. Some riders may miss the upper-rpm surge, but when it’s in its prime torque range, the KDX240 is stronger than many 250s.

Lofting or rock the is now front much wheel easier, over a and log with the engine turning fewer rpm for any given trail speed, the KDX is less tiring to ride;assaulting the engine to go fast is no longer required. Engine response, thanks to spot-on carburetor jetting and the lightened flywheel, is excellent.

The 240’s PPS-modified suspension is equally impressive: Both ends of the bike swallow rocks, ruts and bumps without pounding the rider or bottoming excessively.

This plush suspension and torquemonster engine result in faster trail times, a lot more fun and less rider

fatigue. We’re really happy with our redone KDX240. The engine and suspension modification costs were fairly reasonable for the amount of improvement they provided. Our only regret is that we waited so long to have the modifications made. u

SUPPLIERS Klemm Research 139 N. Maple, Unit G Corona, CA 91720 714/272-8480 240 kit and labor: $589 KIPP spacer: $25 Pipe: $160 Taper-bore carburetor: $65 Lighten flywheel: $65 Answer silencer: $135 PPS 817 Lakeview Dr., Unit B Placentia, CA 92670 714/970-2423 Fork modification: $95 Revalve shock: $150