CYCLE WORLD SERVICE

Turbo cam timing

I have a 1977 GS750 Suzuki with an ATP turbo kit and 870cc turbo pistons. I would like to degree the stock cams to give me an off-boost power increase in the mid-and low-rpm ranges. I am familiar with the process of degreeing bike cams, but I don’t know what lobe-centers to use for my application. What would you recommend?

Joel W. Koontz Bedford, Pa.

Advance the intake cam 2 degrees at a time until you have the engine characteristics you want. Advancing the cam may at first seem the wrong approach because it opens the valves earlier. But the intake valves will also close sooner, and that boosts power at low speeds by not allowing mixture that’s already in the cylinder time to flow back out. You’ll have to insure that there’s clearance between the intake and exhaust valves during the overlap period, as the earlier intake opening will make valve interference more likely.

Tire balancing fluids

i recently brought my bike to the local Honda dealer to have my new pair of tubeless tires mounted and balanced on my stock mags. I found that they don’t balance wheels, but instead spray this green gook called pre-seal directly into the valve stem. They say this balances the wheels. Does it? Is outside rim-weighting better?

Vic Springer Alsip, 111.

Outside rim-weighting is the preferred method of balancing wheels. No one has ever been able to convince us that so-called balancing fluids actually work, and we know of people who have had convincing evidence that these fluids don’t work while running motorcycles at very high speeds on the Bonneville Salt Flats. Also, many tire companies specifically recommend that balancing fluids/sealers should not be used in their tires.

More on Chain Life

IVith regards to the letter from Walt Taylor and your comments regarding O-ring chain life in the December, 1983, Service column: You may be underestimating the serviceability of a properly cared-for chain by a considerable amount.

The original chain on my 1978 Suzuki GS1000 went 34,000 miles and never, never needed adjustment. Towards the end it was chewing up its Orings and was getting stiff. The ^replacement chain, from a wrecked GS1000, went almost 22,000 miles but did require adjustment three times. It may have had its life shortened, however, from a ride through street rivers during a summer rainstorm.

The sprockets on the GS are originals with over 52,000miles, and you would have to be sharp indeed to detect any wear on them. There is now a third chain and the bike is again smooth and quiet, like new.

If you think this is bull, or that I baby my bike, not so. Blast-offs and redlines are seen regularly.

If there is any secret, it is in chain maintenance. I lube the chain with common automotive chassis grease about every 250 300 miles or when the rollers start to look shiny. The grease is applied with a screwdriver blade across a dozen links and is spread around the length of {he chain by the sprockets. Not very much grease is needed; I can carry enough for a trip in a plastic, 35mm film container.

Every 1500 miles I apply a drop of motor oil to each O-ring while the chain is warm. After the spray is wiped off the fcike at the conclusion of the first ride thereafter, the chain area of the bike will stay reasonably clean even with each application of grease.

So one can get many miles and high performance with a minimal mess with a chain. But I will admit that in time, the elimination of any mental and physical hassles provided by a shaft may win over the best benefits of a chain.

Fred Clark Jr. Clearwater, Fla.

Your high mileage from chains represents what can be achieved with some care; a no-maintenance approach 4icould reduce that mileage by threequarters. In our experience, chain life of No. 530 chains tends to be less than that of No. 630 chains as used on your GS. Also, riding in the rain can substantially shorten chain life, so your results may not be repeatable on all motorcycles in all riding conditions.

Automatic valve adjusters

Can you explain how automatic valve adjusters work? Do valves that have this feature ever need attention?

Jim Rock Fairmont, Minn.

Automatic valve adjusters work by imposing a telescoping hydraulic cylinder somewhere between cam and valve. The cylinder is pumped full of ■oil, and when the cam is on the base circle (not pushing on the valve) the cylinder expansion (along with a small helper spring inside each cylinder) > takes up all the clearance in the valve train. When the cam lobe comes around and starts pushing on the cylinder, a check valve in the cylinder closes, trapping the oil inside and effectively making the cylinder a solid, non-compressible unit.

There are two basic variations on this principal. Harley-Davidson big Twins and American automobiles use a hydraulic cylinder (called a “tappet” in those applications) that fits between cam and pushrod, and moves up and down at the same speed as the pushrod. At high speeds, these abrupt changes in direction can confuse the hydraulics, allowing the tappet to compress and the valves to clatter. Recent Honda motorcycles use a hydraulic cylinder that doesn’t reciprocate with the valve gear, but instead regulates the position of the rocker-arm pivot to eliminate clearance in the valve system. This approach survives the high speeds expected of motorcycle engines.

In either case, properly functioning hydraulic valve adjusters eliminate routine valve adjustment. They may, of course, have their own problems and require repair or replacement, but that shouldn't be a common occurrence.

Fix it or torch it

My 1979 Suzuki 750L has been having its problems recently. First the engine was firing on cylinders 1 and 3. So I replaced the dual point ignition with the Dyna III pointless ignition, but didn’t cure the problem. I also changed the plugs around without any difference. Then I replaced the coils with Andrews coils and wires. It worked fine for a couple of days after that, and then the same problem occurred. I purchased Carb Stix to synch the carbs. I wasn’t sure which way to adjust them, up or down, but I chose up. The carbs then started to flood out the overflow tubes. Now I can’t seem to sync the carbs right, the bike won’t go over 35 mph, and I’m ready to torch it and collect the insurance. What should I do next?

J. Jones

Columbus, Ohio

First, keep matches away from your motorcycle and avoid hassles with insurance company attorneys. Then locate the cause of your motorcycle’s poor running.

Because cylinders 1 and 4 operate with one coil, and 2 and 3 on another, we suspect your problem isn’t electrical. That, and the overflow coming from the carbs, points to the possibility of çontaminated fuel. Drain the float bowls and gas tank, then run some fresh ^gas through the system, letting it drain out the float bowls. That alone might cure your problem. If so, a filter between petcock and curbs would help.

If your bike still isn’t running right, start at the beginning: Each cylinder requires compression, a properly timed

spark, and the right fuel-air mixture to fun properly. To avoid frustration, find out which of these conditions is out of order before replacing any parts. Check for a spark at each cylinder, then use a strobe to see if it’s arriving at the right time. If that’s not the problem, check compression next, then fuel to each carburetor, then proper carburetor operation. A service manual can be a valuable aid.

Finally, don’t try to sync the carburetors until everything else is working properly. Suzuki recommends using the number 3 carburetor as the baseline, and adjusting first the number 2 carb to match, then the number l and 4 Tarbs. Only after synchronization should the idle speed be adjusted, so it doesn’t matter how engine speed changes while the carbs are being synced.

Pavement Slider XL

h am building a streetable shorttracker, using a 1982 Honda XL500 motor as a base. Please list the names and addresses of some companies that manufacture frames suitable for my semi-legal, pavement-slider project.

Dotto

La Jolla, Calif.

Try Knight Racing Frames, 25153 O’Neill Ave., Hayward, Calif 94541, phone (415) 582-1333; or C&J Frames, 1151 E. Mission Rd., Fallbrook, Calif. 92028, phone (619) 728-1707. Both Companies offer frame kits (frame, swing arms, and engine mounting hard*ware) for $895, and Knight offers a complete rolling chassis ready to accept your engine for around $3000. O

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsCycle World Editorial

August 1984 By Paul Dean -

Cycle World Letters

Cycle World LettersCycle World Letters

August 1984 -

Departments

DepartmentsCycle World Round Up

August 1984 -

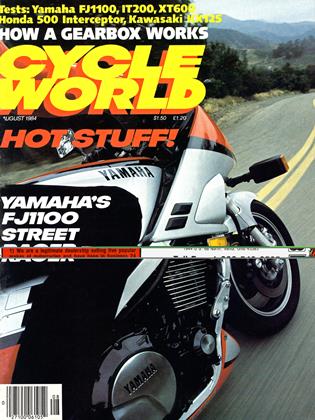

Fj1100 Evolution: Conservative By Design

August 1984 -

Special Features

Special FeaturesHow Motorcycles W·o·r·k 4

August 1984 By Steve Anderson -

Departments

DepartmentsCycle World Race Watch

August 1984