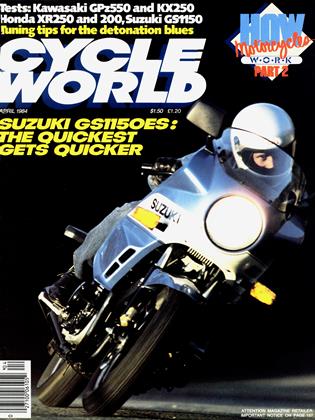

Another cold start solution

SERVICE

I have read the frequent complaints about, and suggested fixes for, Honda cold starting problems in your Service column. The real solution to this problem is simple, and takes only a few minutes to accomplish.

Look at your Honda’s carb and observe whether or not it has a butterfly choke system. If so, the tension exerted to close the butterfly(s) when choked is provided by a small wound spring of approximately six turns. This spring is located around the butterfly shaft, connected solidly at one end to some point on the carb, and to the choke shaft tang at the other end. In many cases the standard supplied tension is not adequate to keep the choke closed in response to engine vacuum during cranking. Inadequate enrichment results, and the engine becomes reluctant to start in cold weather.

To rectify this, do the following. Detach one end of the spring, being careful not to let go. Wind the spring one additional turn and resecure it to the post or tang it was removed from. By doing this you are preloading the spring an additional turn. Be sure you do not coil bind the spring, and that its coils remain lined up and straight. Now activate the choke and check butterfly tension. You will notice a significant increase in closing force.

That's all there is to it. Your cold start problems should be solved. You may need to readjust your choke lever immediately after engine start to avoid possible over-choking in some cases.

My 1978 CX500 and 1980 XL250S had this problem before I modified them as per the above. In the XL's case, the spring is located behind a small round plastic cover on the side of the carb. The CX’s is in view, between the carbs. Both bikes have become almost instant starters, even on khe coldest mornings, since I made this change.

Rob Lentini Tucson, Ariz

Weight distribution

In your May, 1983, issue, you compared the sporting 750s. I noticed the differences between the bikes in weight bias, percent front vs. rear.

Regarding this information, I have some questions:

First, how do you determine these figures? Are the £ikes wet, dry, with rider, or what, when they’re weighed?

Second, and please correct me if Fm wrong, but isn’t the trend these days to get the weight of the bike toward the front? And if that’s true, that’s the Interceptor doing with a 47/53 bias when the GPz and GS share 49/51 ? The Interceptor is supposed to be the “state of the art,” the “wave of the future,” and the “bike of the year.” Well, it seems to me that if that’s progress, the progress is going backwards. What do you think?

Bob Rogers

Seattle, Wash.

We determine a motorcycle’s weight distribution by weighing both ends of the bike when it’s riderless and has half a tank of gas. The two weights added together are the bike’s total weight, and either divided by the total weight is the percentage carried by that end.

It is true that the trend among racing motorcycles has been more and more weight carried on the front wheel, but that trend reflects racing needs. Road race motorcycles seem only to work with short wheelbases (around 54 inches for a 500cc GP bike). Combine a short wheelbase with a sticky rear tire, and the problem is unwanted wheelies. That’s compensated for in part by shifting the bike’s weight forward, more onto the front wheel, to try to keep it in contact with the ground.

But those are racing problems, and don’t exactly parallel the design challenges for 500 pound, 59 inch wheelbase, 750 street bikes. We’re not sure what the best weight distribution is for a sporting 750, and, to be truthful, we don’t worry about it very much. Rather than worry about some theoretically optimum statistic, we prefer to describe how a motorcycle works in actual use, and, in the case of the Interceptor, that’s very well indeed.

Driving light drain

# own a 1981 GS750EX on which I mounted a pair of quartz driving lamps. The instructions provided indicated that the lamps draw their power from a 15 amp,

12 volt accessory fuse on the fuse attached the power leads to. But after riding the bike with the lamps on, the battery is so weak that it can’t turn the engine over after it’s shut down. I took it to a local dealership but they could offer no assistance. Do you have any suggestions?

Jody Walker

Mobile, Ala.

We’ll assume the dealership checked out the charging system and it’s performing normally. In that case, the alternator should be putting out a maximum of 260 watts. The headlight, ignition, and other lights will require about 100 watts of that, so simple arithmetic indicates that you should have 160 watts to run accessories. If your driving lights draw 55 watts apiece, this calculation indicates you should have a power surplus. (It also indicates that you couldn’t run 100 watt bulbs in those lights.)

Unfortunately, this simple calculation doesn’t reflect that the 260 watt rating isn’t> constant, but occurs at a fairly high engine speed. If you're running at engine speeds below 5000 rpm, there’s probably not enough power to run everything without drawing the battery down. Solutions? Run the driving lights for short periods only, and turn them off before you stop so your battery will have some time to recharge.

Or, you can reduce the current draw by running only one of the driving lights. Another approach would be to run the engine at a higher speed than normal by dropping down a gear. That might generate enough power to make up for the deficit.

Hot rod 550

# recently purchased a 1977 Honda CB550F and would like to update it to the level of the current 550 road burners like the Kawasaki GPz550. What improvements should I make to reach this level of handling and performance?

I am already planning to install a Target Products swing arm bushing kit, tapered roller bearings in the steering head, new wheel bearings, and a fork brace.

I plan to use S&W Street Stroker shocks but I don’t know what spring rate I should use. I weigh 180 pounds and will be riding solo most of the time.

I would like to use a set of high performance sport tires. Should I use the widest ones that will fit, or stick with stock sizes? When I change the tires I am going to replace the stock rims with Akront aluminum ones so fitting larger tires shouldn’t be a problem if I need to use wider rims.

I would also like to bring the engine up to the current performance levels. What changes would you suggest?

Leonard Babcock

Madison, Wis.

Your project sounds like fun, but you’re unlikely to match the level of performance found in 1984 500 to 600cc sport bikes. If that’s important to you, you’d be better off investing your money in a new bike. If you want to tinker and build your personal hot rod, here’s what we’d advise: Your suspension changes are a good start for the project. The rear spring rate should be in the 90 to 100 lb./in. range. Slightly larger than original tires would work well: 100/90-19 on the front, and a 110/ 90-18 on the back. Fit a WM-3 rim on the front, and a WM-3 or 4 on the back.

We’d go to Action Fours for engine parts, as they’re very experienced with> the 550 Honda motor. Stick to a moderate engine build-up: the Action Fours’ 601cc big bore kit, a mild camshaft, and a 4-into-l pipe with a quiet baffle. Doing much more than this will probably require stronger connecting rods. Action Fours’ address is 1517 E. McFadden Avenue, Santa Ana, Calif. 92705, phone (714) 541-5341.

Demise of the kick starter

Why is it that all (or most) of the new bikes the manufacturers are putting out do not have kick starters? I just purchased a Honda Interceptor. I love the power it has and all, but what happens when you stop somewhere in the mountains and forget to turn the key off? I’d like to see the return of kickstarters. What do you think?

Andy Tomljenovic

Cape Coral, Fla.

Kick starters went away for three reasons. First, motorcycle electrical systems improved so that electric starting could be depended on. That wasn’t true on late 1960s or early 1970s bikes, but it’s universally the case for current machines. Second, kick starters cost weight, space, and money. If they’re not really needed, the manufacturers have good reasons not to install them. Third, and most important, the manufacturers know that many motorcycle owners look at a kick starter as an admission that the electric starter isn’t quite up to the job, that there’s something inadequate about it. This isn’t an impression that the manufacturer wants to give a potential customer, so kick starters are becoming as rare as chain oilers.

While there are times a kick starter would be handy, you’re not likely to see their return any sooner than the return of the starting crank on cars. What we’d like to see is Honda and Yamaha move the park and lock positions on the ignition to opposite ends of the switch; accidentally leaving bikes in the park (lights-on) position is the only reason we’ve wished for kick starters recently.

Less but lower power for PE175

#’d like to move the torque peak of my PE 175 down a couple of thousand rpm, even if it means losing some off the top. Would shortening the head pipe help? How about increasing expansion chamber volume? Any suggestions, specific or general, will be appreciated.

John Stanford

Pocatello, Idaho

Shortening the head pipe is the wrong approach. Reflected pressure waves in the intake and exhaust system are tuned to arrive back at the intake or exhaust port at a particular time at a particular rpm. If you shorten intake or exhaust, they’ll arrive sooner than desired at that rpm, and at the right time for some higher rpm. The general rule js this: a shorter exhaust or intake pipe for high speed, longer for low speeds.

In practice, you could add about an inch to the PE 175’s exhaust head pipe. To preserve overall power characteristics, you might want to add about 0.3inch to the pipe’s center section as well, but that’s not really necessary. A spacer between the carb and intake tract will drop peak power engine speed also; it would be desirable to add between one and two inches to intake tract length, but that may be complicated by the air box.

Less labor intensive ways to favor low speed power over high speed would be to run slightly more ignition advance than stock (3 degrees or so), or to boost compression ratio. Careful with these mods or the engine will ping itself to death.

Finally, you could drop the exhaust port height. That’s more difficult to do than the more typical raising of the exhaust port for high speed power: You would have to machine material from the base of the cylinder, and add a spacer between cylinder and head to maintain compression ratio. If you choose to do this, shortening the cylinder by about .040 inch would be a reasonable start.

Tubeless tire repair

Are, tubeless tires repairs possible? Practical? Safe? Are dealers equipped to do this, or could they be done by auto tire dealers? Are “canned” puncture repair products even worth considering?

If there are any alternatives to throwing away a punctured tire, I would certainly like to know.

Eric Tucker Pleasanton, Calif.

In your case, Avon doesn’t have a specific policy on repair to tubeless tires. Other tire companies do, but they each have their own policy.

The calls we made to local dealerships indicated that they weren’t very interested in patching tubeless tires, and preferred to install a tube instead.

'if it were our tire, we’d have a automobile tire shop or motorcycle dealership install an internal patch, at least if the manufacturer didn’t specifically recommend against it. Otherwise, we’d install a tube. The aerosol cans containing sealant should be reserved for emergency use, allowing you to reach a place where permanent repairs can be made. >

Perfect Seal

Dirt and dust are two of an engine’s worst enemies. If dirt manages to enter an engine, your pocket book is going to get lighter. Keeping dirt out is especially important on off-road bikes. Most off-road riders already know about greasing the air filter seal and making sure good filter oil is used on the foam filter. But there’s a potential problem area that most riders overlook: the rubber boot between the airbox and carburetor. The seal that keeps dirt from entering the airbox is normally the boot itself. Usually a stamped steel ring bolts over the boot, through the sirbox. If the boot has been carefully assembled to the airbox a good seal is maintained, if not the boot can wrinkle or bunch and dirt can enter. To ensure dirt doesn’t get in, apply silicone seal to each edge of the steel ring making sure there is adequate silicone to touch the steel ring and the rubber boot all the way around the circumference of the boot. If youown a model that has a bolt-on sub frame, the job is really simple. If not it only takes a little longer.

Suzuki GR650 sprockets

A pparently, Cycle World is the only company with the ability to change 1983 GR650 countershaft sprockets. I tried my dealership and PBI, and couldn’t get the sprocket. Would you please send me the sprocket number?

Carl Robson

Woodside, N.Y.

Sprockets for the GR650 are available from PBI (15500 S.E. 102nd, P.O. Box 375, Clackamas, Ore. 97015, phone (503) 655-5128). The number is 670, and you should specify the number of teeth. PBI reports that not all the sprockets they offer are always available through all distributors; if you have trouble locating a particular sprocket, call PBI directly and ask for Jeri Brown. PBI is willing to do oneoffs and custom work.

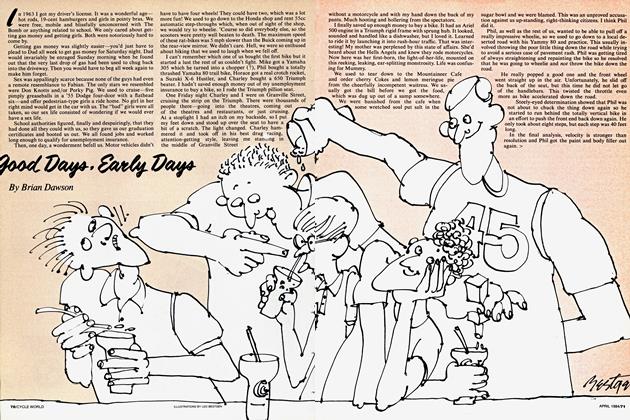

Indian parts

I have a problem. I have an Indian 125 and need parts. None of the local shops can help me. Can you suggest a parts source?

Kenny Williams

Indianapolis, Ind.

Try Bassett Cycles, 2672 South Park Rd., Bethel Park, Pa. 15102, phone (412)833-7278.

View Full Issue

View Full Issue