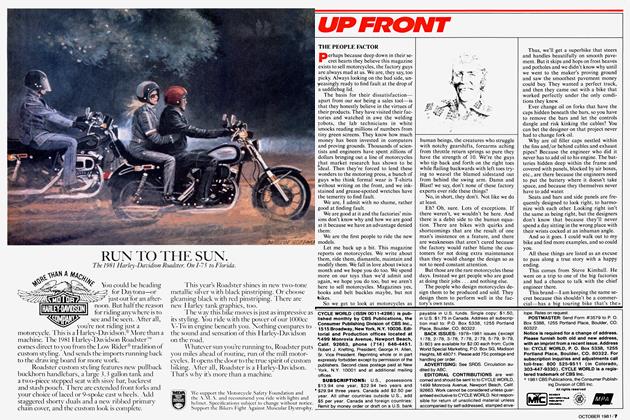

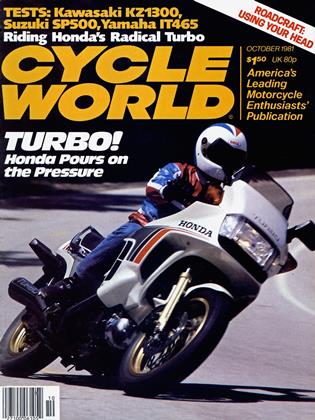

Honda CX500 Turbo

Honda Pours on the Pressure and Proves That Turbocharging Can Work on the Street

Turbocharging has been marketing magic for half a generation. Indy cars and Formula One cars have turbos and when smaller engines became required equipment for road cars, the factories got back the performance image, if not the actual performance, by adding exhaust-driven supercharging and writing “TURBO” in large letters across the car’s flanks.

Then came turbo kits for motorcycles, usually the high-performance Fours and rasty, howling 10-sec. street demons stalked the strips and the run-for-money contests.

But nobody has ever built—let alone sold—anything quite like the fuel-injected, water-cooled, grand-prix-styled Honda CXT

The CX500-based CXT shown here is a prototype, but Honda says only the details will be changed between now' and mid-1982, when the production versions go on sale.

Half a day spent crouched behind the radical fairing was impressive. The turbo cranks out 19 psi above atmospheric pressure, compared with 4 to 11 psi for the bolt-on kits used on engines that weren’t designed for turbos. The extra power is

ready when you are, not just at the drag strip or near the top of the tach. Grab a handful in top gear at 55 mph and the CX Turbo will boost its way past a GS1 100 and leave it behind. The story is the same in fourth and third from the same speeds. Any roll-on contest between the CX Turbo and a GS1100 ends the same way—w'ith the CX ahead.

Which is just the way Honda planned it. Starting early in 1980, K. I noue headed an unheard-of number of engineers—50 at one time—working on the CX Turbo project with three general goals: To develop the world's first mass-produced turboCharged motorcycle with electronic fuel injection; to advance world technological levels regarding turbocharging and injecting small displacement engines; and to offer a total concept motorcycle with a chassis compatible with the increased power.

T There were specific goals, too. Inoue and his men set out to build a CX500 that made more power and torque than the CB900F, delivered more mpg than a standard CX500, and had better throttle response than any other turbocharged motorcycle.

The underlying turbocharger research began at Honda R&D six years ago. At that time, Honda engineers decided that any turbocharged motorcycle had to be watercooled for reliability, and that a Twin would be lighter, simpler and less expensive than a water-cooled Four. The CX500 engine hadn’t reached production yet, and since it was the only water-cooled Twin planned at that time, it became the base engine for the turbo project.

So, before the CX500 engine reached production, the design was revised to allow massive power increases later. For example, the cases were made larger (thicker) and stronger around the clutch hub, so % larger clutch could be installed later. And the main bearing end caps were made big enough to accept larger main bearings later.

There were, however, more serious problems to be overcome than simply strengthening the basic CX engine design. Motorcycle turbocharging technology was aimed primarily at Fours. A four-cylinder engine has an intake stroke every 180° of crankshaft rotation, which means, effectively, that there is always a cylinder ready to accept the charge being blown down the manifolds by the turbo compressor. And because a Four has the same even spacing of exhaust strokes, pulses in the exhaust system are smaller. That means pressure in the exhaust system is relatively even, which works very well to drive the turbocharger turbine at a constant, or steadily-increasing, rate of speed.

V-Twins on the other hand, have intermittant intake strokes, depending upon the angle of the V. Honda’s 500 has two intake strokes every 720° of crankshaft rotation, spaced 280° and 440° apart, so air in the intake manifolds stagnates between intake strokes. V-Twins also have large exhaust gas pulses, or changes in exhaust system pressure. Worse yet, turbocharging development as a whole centered on large displacement engines. Technology for injecting V-Twins, and for electronically controlling fuel injection for V-Twins, was non-existent.

Honda’s work started with the turbocharger itself. Available turbos, including most of the units sold in aftermarket kits, use large automotive-sized turbines. Big engines put out lots of exhaust and in order to get the turbos to spin the desired speed of around 100,000 rpm, the existing turbos are relatively large. About the smallest turbos previously available have turbine intakes of 60mm diameter. That size worked well on engines as small as 2000cc, but on motorcycles that wouldn’t provide any measure of boost until engine speed was near redline. So working with the Japanese turbo manufacturer, IHI, Honda developed a 48mm compressor with an integral waste gate to limit boost pressure by bleeding off excess.

In the course of development, nine different compressor/compressor-housing combinations and eight different turbine/ turbine-housing design combinations were tried, each different design affecting performance.

Bolting on the finished IHI turbocharger made a CX500 engine with better throttle response, earlier boost, and more mid-range torque compared with a CX500 engine with a 60mm turbo. But the biggest gains in throttle response and torque curve came with the addition of two chambers between the compressor and the cylinder heads. The chambers provide a place for the pressurized, incoming air to go when the intake valves are closed, maintaining charge velocity and avoiding stagnation.

The idea isn’t new, appearing in the 1978 edition of the standard reference work on turbocharging, Turbochargers, by Hugh Maclnnes. In his book, Maclnnes recommends the use of a plenum chamber on the intake manifold of twincylinder engines, and says that the volume of all the pipes leading from compressor to the cylinder heads should be two or three times that of one cylinder. Otherwise, Maclnnes warns, manifold pressure at high rpm will fall even though the compressor could flow more air.

While the idea is not new, the execution is. Honda engineers found that the exact placement, size and shape of the two chambers had major effects on performance. Honda calls the first, and smaller of the chambers, a resonance chamber, and says that it is most important at lower rpm. The second, larger chamber, positioned closer to the cylinder heads, is called the surge tank and has the most effect at higher rpm. A butterfly throttle valve is located between the surge tank and each intake manifold.

In the course of building the CX500 Turbo, Honda applied for 250 patents. Of

the ones dealing with the turbocharging system, the majority apply to size, shape and placement of the resonance chamber and the surge tank.

A reed valve installed in the airbox prevents pressure in the resonance chamber and surge tank from backing up into the airbox upon deceleration. The pressure is instead routed through a baffled silencing chamber adjacent to the airbox, then into the airbox itself. The result is less noise.

The fuel injection system is as interesting as the turbocharging system. How much fuel is injected, and when it is injected, is controlled by a digital computer. The computer gathers information from seven sensors and an electronic air flow meter, combining measurements of boost pressure, throttle opening and rpm to determine injection quantities. The sensors read pressure (P, in the accompanying diagram) and temperature (T,) between the airbox and the compressor; pressure in the surge tank (P2) and intake manifold (indicated PB, with two sensors used for safety); throttle opening; and coolant temperature (Tw). Injection pressure varies according to boost pressure. As pressure in the intake manifold rises, so does pressure rise in the fuel injection system, ensuring that the injected fuel sprays into the manifold at a given relative pressure.

Preventing detonation (or pre-ignition) while running 19 psi boost on pump gas without water injection is a major consideration. To keep the engine from detonating itself to pieces, c.r. is a low, low 7.2:1 (a standard CX engine has 10:1 c.r.) and ignition timing is electronically controlled according to rpm and boost pressure. As boost rises or rpm drops, ignition timing is retarded, so full advance is reached under low-load, higher rpm conditions. Fullthrottle, fuel-boost operation at relatively lower rpm results in more retarded timing.

Using a computer to control fuel injection is common enough, but most injection computers measure only throttle opening and rpm, which is all that’s required on a normally aspirated engine. The CX500 Turbo’s computer is more complicated because it must also take into consideration boost pressure. Determining injection quantity by rpm and boost pressure yields the best performance at low rpm, low load; and determining injection quantity by rpm and throttle opening yields best performance at high rpm, high load. (In case of boost exceeding 19 psi, the computer shuts off the fuel supply.)

The system can function at reduced efficiency (with less performance) reading only rpm and throttle opening or only rpm and boost pressure, so if one system fails (as if the boost sensors stop working), the bike can limp home on the other system without requiring an emergency airlift bringing in a new computer. The system is also self-diagnosing. The computer housing includes five light emitting diodes (LED) along one side. If, for example, the second and fifth LED are lit, that means that the number one boost sensor is not working. To restore full operation, the owner or mechanic replaces the sensor (or repairs or replaces faulty wiring from the sensor to the computer) and in theory, the system is back to normal.

Honda spokesmen say that if the computer itself fails, riders will be able to exchange it for another computer. Computers needing repairs will be fixed at a service center and traded to owners of failed computers. Details were not available regarding repair cost, but it should be less expensive than buying a new computer in case of a failure.

The whole system results in a CX500 engine that makes a claimed 77 bhp, about 30 bhp more than a standard CX. As pressure in the cylinder rises, it’s harder to fire the mixture, so the CX500 Turbo has a transistorized, inductive, battery-powered electronic ignition (replacing the standard model’s magneto CDI) with larger coils. The pistons are forged (a first for a stock street bike) with stronger wrist pins. Connecting rods are also stronger, with design and material changes. There’s a new crankshaft, and big end and main bearings are increased in capacity.

The engine now has an automatic tensioner for the link-plate cam chain, and a larger rocker arm assembly. Valves are smaller, with valve guide and valve seat material changed to handle the additional heat generated by the increased power.

Valve timing is altered, being made milder, the intake valves opening 5° BTDC and closing 30° ABDC; the exhaust valves opening 30° BBDC and closing 5° ATDC (measured from 1mm lift).

Transmission gears have machined engagement dogs and ratios are changed. The clutch is larger, being the same size as the clutch used in the GL1100, with more plates. The radiator is larger, as is the water pump. The cooling system flows more water.

The oil sump is larger, t^o. A thickfinned, heat-sink-looking oil cooler bolts to the bottom of the crankcases ahead of the large sump.

The chassis is based on the Pro-Link GL500 frame, but geometry is slightly different. The frame is more heavily gusseted and the Pro-Link linkage is different to reflect the sport orientation of the motorcycle. The swing arm is aluminum, as is the rear brake caliper stay arm. Air-assisted suspension is used front and rear and the fork stanchion tubes are 37mm in diameter. The CX500 Turbo has three 10.9-in. disc brakes, two mounted up front, and the brake pads have a higher metal content than those on the GL500 and CX500. The all-alloy, three-spoke Comstar wheels are patterned after

wheels developed for the NR500 GP racebike and have relatively wide rims— 2.50-in. front and rear vs. the CX500’^ 2.15-in. The front rim is 18-in., the rear, 17-in. Tire are V-rated, a 3.50-18 Bridgestone L303 front and a 120/90-17 Bridgestone G508 rear.

The most visible part of the CX500 Turbo is the fairing, and it received almost as much attention as the engine. Honda engineers spent a month working on fairing and front fender design in a wind tunnel. The result is a landmark in aerodynamics and rider comfort.

Reducing frontal area is an obvious goal of fairing design. Honda combined that consideration with rider comfort by carefully placing, sizing and shaping the front turn signals on the outside edges of the fairing (where they protect the rider’s hands from wind and rain) and by deflecting hot air from the radiator outward, around and away from the rider. The air cleaner is accessible through the right side of the fairing, and an air scoop below the" huge (8.75 x 5.75-in.) quartz-halogen headlight directs cold air to the air cleaner. The turbo resonance tank is located in the left side of the fairing. Dual horns ride inside the fairing air scoop.

The CX500 Turbo shouldn’t be thought of as a 500-cc motorcycle with the power of an 1100.

Instead, in view of the 560-lb. weight and the 59-in. wheelbase, the CXT should be thought of as a big motorcycle with the weight and performance that come with 77 bhp, even if the power is produced in a different way.

Riding several prototypes reinforced that viewpoint. The new Honda made lots of peak power, and boost kicked in Strongly at 5500-6000 rpm, depending upon altitude (which, for this riding session, varied from 1000 to 7000 ft. above sea level). As altitude increased, the CX500 Turbo’s power advantage over other bikes also increased, since peak boost remained at 19 psi above ambient pressure.

Honda’s engineering work has produced a turbocharged engine with less throttle lag (the interval between opening the throttle and getting acceleration) than any other turbocharged motorcycle we’ve ridden. But there still is a bit of lag. In the previously-mentioned roll-ons against a GS 1100, the Suzuki jumped half a length or a length ahead in the split second it took the Honda to react to the suddenly-opened throttle. When it reacted, it reacted, instantly jumping up to and then past the larger displacement machine. The lag was present when the throttle was closed, too, Tooling one rider into thinking for a moment that the throttle was sticking on.

On twisty canyon roads at a fast pace, the Honda’s boost kick-in complicates corner exits. Ride around a corner at 4500 rpm and twist the throttle to accelerate out and there’s a big increase in power at 5500 rpm. That increase in power changes chassis loading and makes for less-thansmooth exits. Riding a GS1100 around the same turn at the same rpm and rolling on the throttle produces nothing but a quick getaway.

To ride the Honda smoothly at fast speeds on curvy roads requires keeping the rpm up around 8000-10,500 rpm, where boost and power delivery are relatively constant. As a result, 90 mi. of mostly-wide-open mountain roads with short freeway stretches dropped mileage to 19 mpg, from the EPA claimed estimates of 53 mpg city and 57 mpg highway.

As for the rest of the bike, it works pretty well. The brakes are excellent, the chassis and suspension—and, as a result, handling—good at near-breakneck speeds. Slow down to a moderately-fast cruise and it feels as if the Pro-Link spring rates aren’t quite right, the softest, most responsive part of rear suspension travel being used up at the entrance to a turn,

with nothing but a harder, too-stiff rate left to handle (or, in this case, not handle) small bumps mid-turn.

Detail specifications are subject to change before production starts. Spring rates and Pro-Link linkages may be different when the CX500 Turbo hits the streets en masse, if a production run of one-perHonda-dealer can be called en masse.

If the production models are even close to the prototypes, the CX500 Turbo will be amazing. Consider the scene when your non-riding neighbor strolls over to look at your new motorcycle. With the magic words “turbocharged, with electronic fuel injection and watercooling,” he’ll know you’ve got one heck of a bike, and so must be one heck of a guy. It might even make motorcycles interesting to him, or impress him to find that this motorcycle has more advanced technology than anything available out of Detroit.

The Honda CX500 Turbo is impressive, because it looks the way it does, and has the gadgets it has. It is a technical masterpiece, a demonstration of engineering skill, a flexing of Honda’s cerebral muscles.

View Full Issue

View Full Issue