FOX FACTORY FORX

EVALUATION

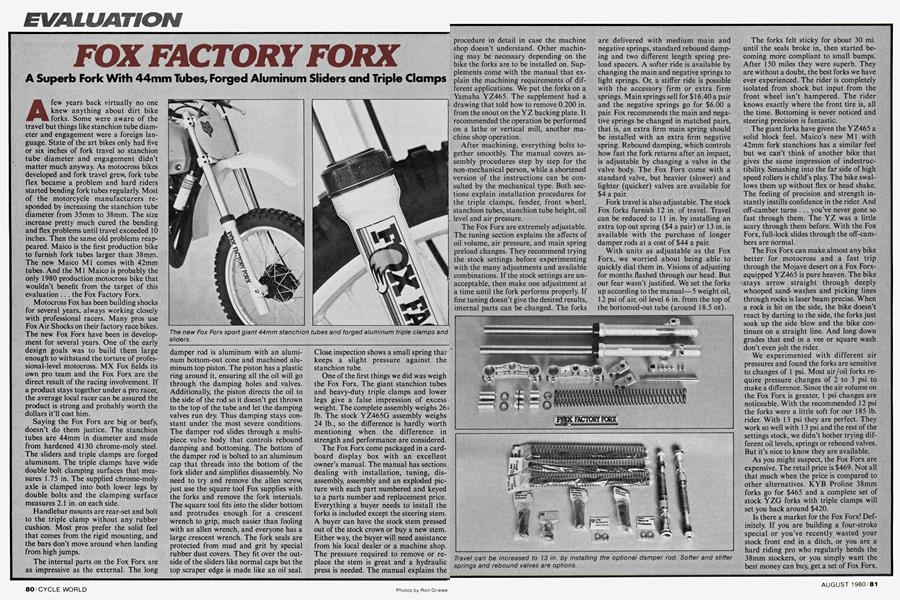

A Superb Fork With 44mm Tubes, Forged Aluminum Sliders and Triple Clamps

A few years back virtually no one knew anything about dirt bike forks. Some were aware of the travel but things like stanchion tube diameter and engagement were a foreign language. State of the art bikes only had five or six inches of fork travel so stanchion tube diameter and engagement didn't matter much anyway. As motocross bikes developed and fork travel grew, fork tube flex became a problem and hard riders started bending fork tubes regularly. Most of the motorcycle manufacturers responded by increasing the stanchion tube diameter from 35mm to 38mm. The size increase pretty much cured the bending and flex problems until travel exceeded 10 inches. Then the same old problems reappeared. Maico is the first production bike to furnish fork tubes larger than 38mm. The new Maico M1 comes with 42mm tubes. And the M1 Maico is probably the only 1980 production motocross bike that wouldn't benefit from the target of this evaluation. . . the Fox Factory Forx.

Motocross Fox has been building shocks for several years, always working closely with professional racers. Many pros use Fox Air Shocks on their factory race bikes. The new Fox Forx have been in development for several years. One of the early design goals was to build them large enough to withstand the torture of professional-level motocross. MX Fox fields its own pro team and the Fox Forx are the direct result of the racing involvement. If a product stays together under a pro racer, the average local racer can be assured the product is strong and probably worth the dollars it’ll cost him.

Saying the Fox Forx are big or beefy, doesn’t do them justice. The stanchion tubes are 44mm in diameter and made from hardened 4130 chrome-moly steel. The sliders and triple clamps are forged aluminum. The triple clamps have wide double bolt clamping surfaces that measures 1.75 in. The supplied chrome-moly axle is clamped into both lower legs by double bolts and the clamping surface measures 2.1 in. on each side.

Handlebar mounts are rear-set and bolt to the triple clamp without any rubber cushion. Most pros prefer the solid feel that comes from the rigid mounting, and the bars don’t move around when landing from high jumps.

The internal parts on the Fox Forx are as impressive as the external. The long damper rod is aluminum with an aluminum bottom-out cone and machined aluminum top piston. The piston has a plastic ring around it, ensuring all the oil will go through the damping holes and valves. Additionally, the piston directs the oil to the side of the rod so it doesn’t get thrown to the top of the tube and let the damping valves run dry. Thus damping stays constant under the most severe conditions. The damper rod slides through a multipiece valve body that controls rebound damping and bottoming. The bottom of the damper rod is bolted to an aluminum cap that threads into the bottom of the fork slider and simplifies disassembly. No need to try and remove the alien screw, just use the square tool Fox supplies with the forks and remove the fork internals. The square tool fits into the slider bottom and protrudes enough for a crescent wrench to grip, much easier than fooling with an alien wrench, and everyone has a large crescent wrench. The fork seals are protected from mud and grit by special rubber dust covers. They fit over the outside of the sliders like normal caps but the top scraper edge is made like an oil seal. Close inspection shows a small spring that keeps a slight pressure against the stanchion tube.

One of the first things we did was weigh the Fox Forx. The giant stanchion tubes and heavy-duty triple clamps and lower legs give a false impression of excess weight. The complete assembly weighs 26 lb. The stock YZ465G assembly weighs 24 lb., so the difference is hardly worth mentioning when the difference in strength and performance are considered.

The Fox Forx come packaged in a cardboard display box with an excellent owner’s manual. The manual has sections dealing with installation, tuning, disassembly, assembly and an exploded picture with each part numbered and keyed to a parts number and replacement price. Everything a buyer needs to install the forks is included except the steering stem. A buyer can have the stock stem pressed out of the stock crown or buy a new stem. Either way, the buyer will need assistance from his local dealer or a machine shop. The pressure required to remove or replace the stem is great and a hydraulic press is needed. The manual explains the procedure in detail in case the machine shop doesn’t understand. Other machining may be necessary depending on the bike the forks are to be installed on. Supplements come with the manual that explain the machining requirements of different applications. We put the forks on a Yamaha YZ465. The supplement had a drawing that told how to remove 0.200 in. from the snout on the YZ backing plate. It recommended the operation be performed on a lathe or vertical mill, another machine shop operation.

After machining, everything bolts together smoothly. The manual covers assembly procedures step by step for the non-mechanical person, while a shortened version of the instructions can be consulted by the mechanical type. Both sections explain installation procedures for the triple clamps, fender, front wheel, stanchion tubes, stanchion tube height, oil level and air pressure.

The Fox Forx are extremely adjustable. The tuning section explains the affects of oil volume, air pressure, and main spring preload changes. They recommend trying the stock settings before experimenting with the many adjustments and available combinations. If the stock settings are unacceptable, then make one adjustment at a time until the fork performs properly. If fine tuning doesn’t give the desired results, internal parts can be changed. The forks are delivered with medium main and negative springs, standard rebound damping and two different length spring preload spacers. A softer ride is available by changing the main and negative springs to light springs. Or, a stiffer ride is possible with the accessory firm or extra firm springs. Main springs sell for $ 16.40 a pair and the negative springs go for $6.00 a pair. Fox recommends the main and negative springs be changed in matched pairs, that is, an extra firm main spring should be installed with an extra firm negative spring. Rebound damping, which controls how fast the fork returns after an impact, is adjustable by changing a valve in the valve body. The Fox Forx come with a standard valve, but heavier (slower) and lighter (quicker) valves are available for $4 a pair.

Fork travel is also adjustable. The stock Fox forks furnish 12 in. of travel. Travel can be reduced to 11 in. by installing an extra top out spring ($4 a pair) or 13 in. is available with the purchase of longer damper rods at a cost of $44 a pair.

With units as adjustable as the Fox Forx, we worried about being able to quickly dial them in. Visions of adjusting for months flashed through our head. But our fear wasn’t justified. We set the forks up according to the manual—5 weight oil, 12 psi of air, oil level 6 in. from the top of the bottomed-out tube (around 18.5 oz).\

The forks felt sticky for about 30 mi. until the seals broke in, then started becoming more compliant to small bumps. After 150 miles they were superb. They are without a doubt, the best forks we have ever experienced. The rider is completely isolated from shock but input from the front wheel isn’t hampered. The rider knows exactly where the front tire is, all the time. Bottoming is never noticed and steering precision is fantastic.

The giant forks have given the YZ465 a solid block feel. Maico’s new Ml with 42mm fork stanchions has a similar feel but we can’t think of another bike that gives the same impression of indestructibility. Smashing into the far side of high speed rollers is child’s play. The bike swallows them up without flex or head shake. The feeling of precision and strength instantly instills confidence in the rider. And off-camber turns ... you’ve never gone so fast through them. The YZ was a little scary through them before. With the Fox Forx, full-lock slides through the off-cambers are normal.

The Fox Forx can make almost any bike better for motocross and a fast trip through the Mojave desert on a Fox Forxequipped YZ465 is pure heaven. The bike stays arrow straight through deeply whooped sand* washes and picking lines through rocks is laser beam precise. When a rock is hit on the side, the bike doesn’t react by darting to the side, the forks just soak up the side blow and the bike continues on a straight line. And long down grades that end in a vee or square wash don’t even jolt the rider.

We experimented with different air pressures and found the forks are sensitive to changes of 1 psi. Most air/oil forks require pressure changes of 2 to 3 psi to make a difference. Since the air volume on the Fox Forx is greater, 1 psi changes are noticeable. With the recommended 12 psi the forks were a little soft for our 185 lb. rider. With 13 psi they are perfect. They work so well with 13 psi and the rest of the settings stock, we didn’t bother trying different oil levels, springs or rebound valves. But it’s nice to know they are available.

As you might suspect, the Fox Forx are expensive. The retail price is $469. Not all that much when the price is compared to other alternatives. KYB Proline 38mm forks go for $465 and a complete set of stock YZG forks with triple clamps will set you back around $420.

Is there a market for the Fox Forx! Definitely. If you are building a four-stroke special or you’ve recently wasted your stock front end in a ditch, or you are a hard riding pro who regularly bends the 38mm stockers, or you simply want the best money can buy, get a set of Fox Forx.

View Full Issue

View Full Issue

More From This Issue

-

Departments

DepartmentsUp Front

August 1980 By Allan Girdler -

Letters

LettersLetters

August 1980 -

Departments

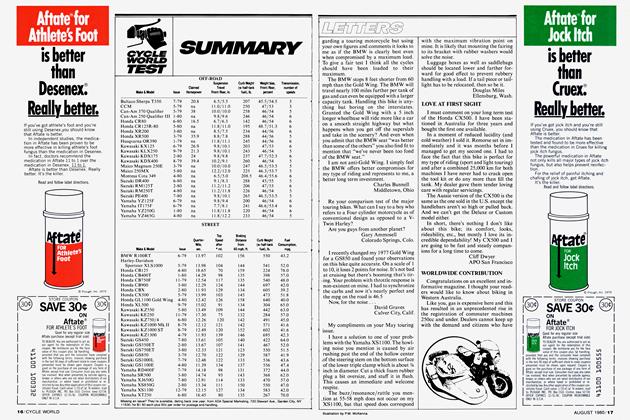

DepartmentsSummary

August 1980 -

Books

BooksAmerican Racer

August 1980 By Henry N. Manney III -

Books

BooksRestoring And Tuning of Classic Motorcycles

August 1980 By Henry N. Manney III -

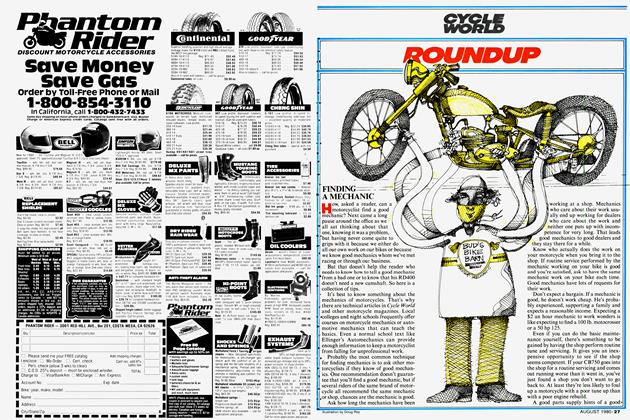

Departments

DepartmentsCycle World Roundup

August 1980 By Henry N. Manney III