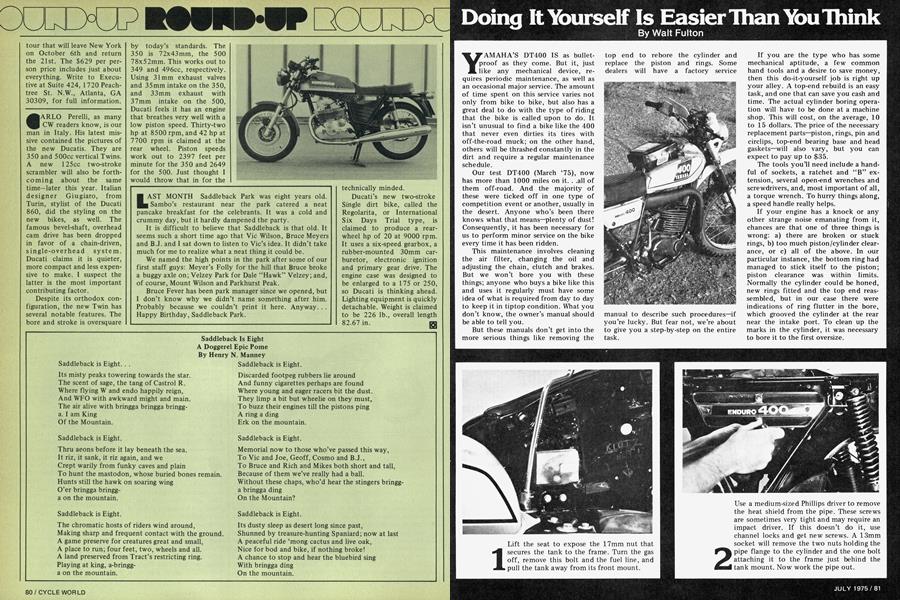

Doing It YOurself Is Easier Than YOU Think

Walt Fulton

YAMAHA'S DT400 IS as bullet-proof as they come. But it, just like any mechanical device, requires periodic maintenance, as well as an occasional major service. The amount of time spent on this service varies not only from bike to bike, but also has a great deal to do with the type of riding that the bike is called upon to do. It isn’t unusual to find a bike like the 400 that never even dirties its tires with off-the-road muck; on the other hand, others will be thrashed constantly in the dirt and require a regular maintenance schedule.

Our test DT400 (March ‘75), now has more than 1000 miles on it. . .all of them off-road. And the majority of these were ticked off in one type of competition event or another, usually in the desert. Anyone who’s been there knows what that means—plenty of dust! Consequently, it has been necessary for us to perform minor service on the bike every time it has been ridden.

This maintenance involves cleaning the air filter, changing the oil and adjusting the chain, clutch and brakes. But we won’t bore you with these things; anyone who buys a bike like this and uses it regularly must have some idea of what is required from day to day to keep it in tiptop condition. What you don’t know, the owner’s manual should be able to tell you.

But these manuals don’t get into the more serious things like removing the

top end to rebore the cylinder and replace the piston and rings. Some dealers will have a factory service

manual to describe such procedures—if you’re lucky. But fear not, we’re about to give you a step-by-step on the entire task.

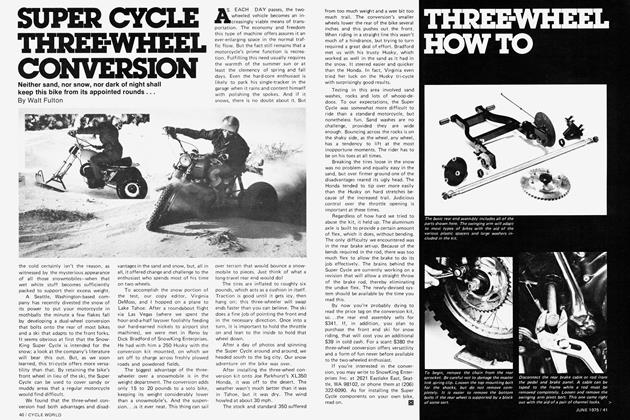

If you are the type who has some mechanical aptitude, a few common hand tools and a desire to save money, then this do-it-yourself job is right up your alley. A top-end rebuild is an easy task, and one that can save you cash and time. The actual cylinder boring operation will have to be done at a machine shop. This will cost, on the average, 10 to 15 dollars. The price of the necessary replacement parts—piston, rings, pin and circlips, top-end bearing base and head gaskets—will also vary, but you can expect to pay up to $35.

The tools you’ll need include a handful of sockets, a ratchet and “B” extension, several open-end wrenches and screwdrivers, and, most important of all, a torque wrench. To hurry things along, a speed handle really helps.

If your engine has a knock or any other strange noise emanating from it, chances are that one of three things is wrong: a) there are broken or stuck rings, b) too much piston/cylinder clearance, or c) all of the above. In our particular instance, the bottom ring had managed to stick itself to the piston; piston clearance was within limits. Normally the cylinder could be honed, new rings fitted and the top end reassembled, but in our case there were indications of ring flutter in the bore, which grooved the cylinder at the rear near the intake port. To clean up the marks in the cylinder, it was necessary to bore it to the first oversize.

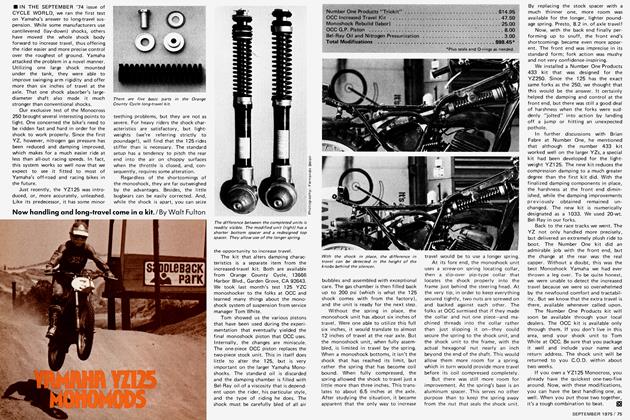

10 Before proceeding, clean any gasket material from the crankcase and cylinder. Also, use a scraper to remove any carbon buildup that has accumulated in the head. Thoroughly wash the cylinder in solvent to remove any particles left over from the bore job. Install the decompression release and the reed-valve block. Tighten the block down evenly.

15 Push the carb into the spigot, making sure it is positioned correctly. Don’t forget to tighten the clamp.