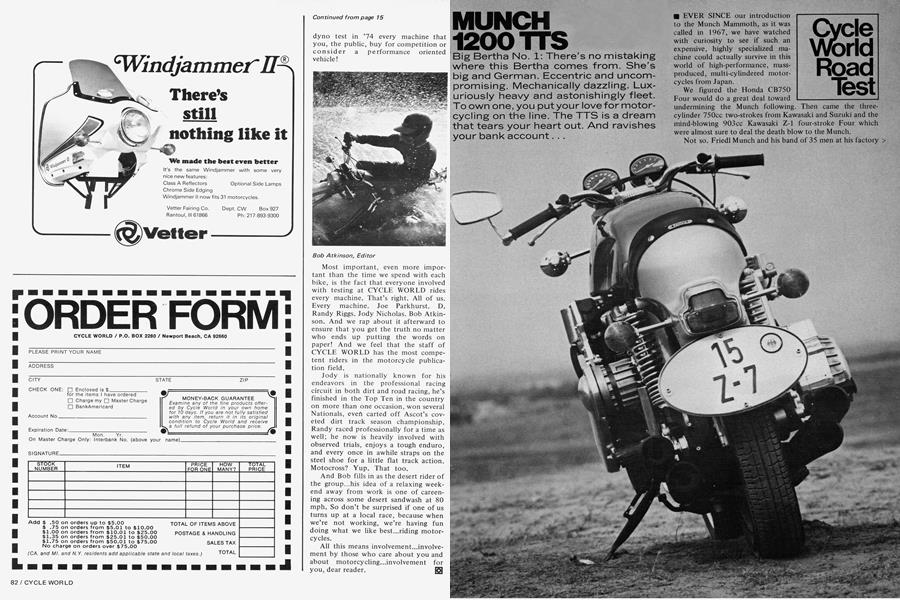

MUNCH 1200 TTS

Cycle World Road Test

Big Bertha No. 1: There’s no mistaking where this Bertha comes from. She’s big and German. Eccentric and uncompromising. Mechanically dazzling. Luxuriously heavy and astonishingly fleet. To own one, you put your love for motorcycling on the line. The TTS is a dream that tears your heart out. And ravishes your bank account. . .

EVER SINCE our introduction to the Munch Mammoth, as it was called in 1967, we have watched with curiosity to see if such an expensive, highly specialized machine could actually survive in this world of high-performance, mass-produced, multi-cy lindered motorcycles from Japan.

We figured the Honda CB750 Four would do a great deal toward

undermining the Munch following. Then came the threecylinder 750cc two-strokes from Kawasaki and Suzuki and the mind-blowing 903cc Kawasaki Z-l four-stroke Four which were almost sure to deal the death blow to the Munch.

Not so. Friedl Munch and his band of 35 men at his factory in West Germany have been able to sell all the motorcycles they’ve been able to produce. And they’re now expanding to satisfy the larger demand created by the special enthusiast who still wants the biggest, fastest and best built motorcycle available in the world today. There are more of this type of motorcyclist than one might be led to believe.

The late Floyd Clymer, author and publisher of hundreds of books pertaining to all types of mechanized vehicles, began importing the Munch Mammoth on a small scale as long ago as 1967. But the factory’s inability to keep up with the number of orders and Clymer’s death all but stopped the flow of the Munch into America.

Meanwhile, Munch and company were busy in Germany, making subtle refinements and slight design changes which were being requested by the European cafe racer and enthusiast—the people who were actually buying the machine.

It’s interesting to note that there are no apprentices at the Munch factory. Most of the employees are masters of their trade, and the end product shows it. There are no sloppy welds, ill-fitting parts or lack of attention to detail. Each Munch is a work of art, finished to the customer’s specifications. In fact, there have probably not been two Munchs exactly alike to leave the factory.

At the time of this writing, the Munch organization is setting up a series of five service centers across the United States which will have spare parts and the facilities to do any repairs that might be needed. However, each new Munch 1200 TTS will be ordered directly from the factory to the customer’s exact specifications and then shipped or air freighted to a U.S. port of entry. The present production of 30 machines per month will soon be up to 50, with greater numbers to follow as the demand warrants.

The original lOOOcc NSU automobile engine which powered the Munch has been enlarged to almost 1200cc and is now fitted with two aluminum cylinder barrels instead of the earlier cast iron units. This saves weight and permits engine temperatures to be kept somewhat lower, especially since there is more finning on the aluminum barrels.

NSU supplies the engines to Munch as they would be put into an automobile. But there’s where the work begins. Each engine is stripped, then the cooling fan, flywheel and cooling shroud are removed and the engine is dismantled. Some of the mounting point castings are strengthened and remachined.

The five-main bearing crankshaft, from which the flywheel has been removed, is dynamically balanced after the primary drive gear and the alternator pulley are installed. Munch remachines the crankcase to accept the aluminum cylinders, and as a final touch, sandblasts the crankcase and applies a heat-resistant black paint.

Then comes reassembly of the engine, without the NSU pressed steel oil pan and the NSU oil cooler. A special oil sump which increases the engine’s oil capacity to 9.5 U.S. pints is fitted. Its design and cast magnesium construction strengthens the entire crankcase.

The NSU cylinder head has special inlet and exhaust port configurations to permit better breathing at high engine speeds, and there are several camshaft options from which the customer may choose. The TTS cam installed in our test machine is a “medium” grind permitting good low speed characteristics and safe engine revs to 8000 rpm even though the power starts falling off over 6500 rpm.

Twin-throat Weber 40 DCOE carburetors with 30mm venturis nestle behind the cylinder head. They are attached to the head by special neoprene rubber manifolds to eliminate problems with fuel frothing caused by engine vibration. A Bosch electric fuel pump keeps the carburetor floats filled to the correct levels.

A twin-row chain from the left hand end ot the crankshaft drives the single overhead cam. Most overhead cam motorcycles have a single-row chain coming up through a tunnel between the center two cylinders. Just outboard of the lower cam chain sprocket is a pulley for the V-belt which drives the Bosch automotive-type alternator. Covers for the cam chain and the alternator V-belt are smooth, highly polished aluminum.

Munch takes a slightly different approach to driving the clutch from the crankshaft on his inline four-cylinder motorcycle. A helical gear on the right hand end of the crankshaft mates with a similar gear on the transmission mainshaft in which the 5-plate dry clutch housing is located. Although the gear drive is quite near the outside of the engine, gear whine is almost inaudible.

The ignition distributor, which has been moved from its original position at the end of the camshaft, now nestles in front of the engine and is driven by a single-row chain with a tensioner pulley off the right hand end of the crankshaft. The distributor is encased in a plastic “sock” which terminates near the top front of the cam chain cover. Each wire comes through a hole in a device which looks like a test tube stopper, ensuring that no water will find its way into the distributor.

An engine which develops so much power needs a strong transmission, and that’s exactly the word to describe the Munch’s gearbox. The gearset is a slightly modified Hurthsystem one, like those found on the old Horex Imperator 400cc Twin of several years ago. Three huge bearings support the output shaft of the transmission. The shift lever is on the left hand side and the rather unfamiliar one up, three down shifting pattern is used. Shift lever throw is short and gear engagement is positive, although noisy. Munch’s representative tells us that a braking device will soon be added to the clutch hub to help synchronize engine and gearbox speeds and eliminate the crunch from shifting gears.

Although not equipped with a kick starter, twin Bosch batteries, wired in parallel, provide more than enough juice to rapidly spin the engine over, even when the outside air temperature is cool. You’ll find the Bosch electric starter above the transmission case, just behind the right hand cylinders.

The totally enclosed 5/8x3/8 rear chain which runs in an oil bath is probably the most interesting part in the motorcycle’s driveline. It has an adjustable idler gear to adjust chain tension without moving the rear wheel. The entire swinging arm is a massively robust assembly which is cast from magnesium.

Also cast of magnesium is the vane-type rear wheel which is fitted with a 10-in. diameter twin-leading shoe brake. Peculiar looking at first, the wheel complements the massiveness of the motorcycle’s rear section.

Adjustable rear shock absorbers, made by Koni, allow adjustment of both the spring and damping rates. On the standard settings, they are just right for a 160-lb. rider.

Front suspension is handled admirably by a set of Rickman motocross pattern forks. These have enormously strong stanchions which provide adequate support and movement on rough surfaced roads. A rigid steering assembly is a must on any machine that will be ridden fast. Undue flexing up front will cause the rider to be uncomfortable, possibly physically as well as mentally, and more especially on a fast, heavy machine like the 1200 TTS. Throwing the TTS into fast, choppy corners proved the worth of the excellent suspension.

Of great importance to the rider of a fast, heavy motorcycle is its stopping power. Enormous twin-leading shoe brakes on both wheels are well up to the job of bringing the 1200 TTS down from high speeds with a good margin of safety. Even though the front brake began to fade slightly after our second 60-0 mph deceleration test, it stood up well to the job of bringing 745 lb. down to a standstill. We understand that a twin-disc front brake will be offered as an option in the near future. If the rider is inclined toward making his way briskly through hilly country, such a brake would be an asset.

The rear brake is now cable operated instead of having a hydraulic actuation system as did the Munch we rode in 1967, and it proved to be more than adequate in its job, giving good feel without requiring heavy pedal pressure.

A pair of oil coolers is another recent addition to the 1200 TTS. One is mounted in front and slightly under each side of the gas tank. These are polished aluminum castings which are as attractive as they are functional. Oil coming from the engine is fed into one cooler and then crossed to the other cooler through a neoprene hose before it is returned to the engine’s sump.

The massive double cradle frame looks very similar to the recent Norton “Featherbed” frames and is heavily gusseted at points of stress. The engine/gearbox unit is bolted to both the horizontal and transverse frame members.

Of interest is the rear fender/seat unit which is a magnesium casting featuring pleasantly styled lines and ample room on the seat. The seat covering detaches easily. Under the front portion is one of the batteries and the tool kit fits in the hump at the rear over the taillight.

There are so many options that the buyer of a Munch may order that we will only comment on the way our test machine was delivered. The handmade aluminum gas tank was the smaller of the two offered, but still held nearly 5.5 U.S. gallons of fuel. Each tank is fabricated by hand and just knowing that no machine other than a welding torch had anything to do with its construction is satisfying indeed.

Impressively robust aluminum side covers under the seat are secured to their bodies by alien head socket screws. One covers the battery and the other conceals the array of electrical wiring and switching components.

MUNCH 1200 TTS

$4750

Handlebar controls on the short (26-in. wide) handlebars are similar to the ones found on the BMW R60US we tested in the Aug. ’72 issue of CW. The same turn signal switch is located on the right handlebar near the twistgrip. A similar switch on the left handlebar controls the high and low headlamp beams and has a position that allows the rider to flash the high beam for overtaking slower traffic. In spite of the two Weber carburetors and their return springs, throttle operation wasn’t too difficult, and the clutch lever was remarkably easy to withdraw.

Many pictures of the Munch 1200 TTS already published show the machine with twin headlights mounted side by side, but models sold in the U.S. will have a single, large headlamp which is more than adequate for riding at U.S. legal highway speeds.

Riding the 1200 TTS is a delight in more ways than one. The most significant feeling the rider gets is quietly gliding down the street, knowing that dozens of pairs of eyes are watching him. The sheer size of the machine gets the onlookers’ curiosity up, and the complicated mechanicalness holds even the neophyte motorcyclist spellbound.

A large, heavy machine with steering geometry designed for high speed cruising can be a handful in town. The Munch is no exception. Smaller riders carrying a passenger will have their hands full while threading through rush hour traffic. Part of the problem is the narrow handlebars. Although they are just dandy for freeway cruising, they are too narrow to give the rider sufficient leverage to turn the Munch in traffic.

The seat is low (28 in.) and is wide enough to provide good comfort for long trips. The passenger portion is also comfortable and the relationship between the passenger’s seating position and the footpegs is comfortable, even for tall people.

The lowness of the seating position and the large gas tank makes the rider feel more a part of the machine than just an accessory which has been tacked on top.

The Munch 1200 TTS is an expensive motorcycle, but close scrutiny of the many handmade and precisely machined components will show you why. Many options are also available: safety bars, $69; luggage rack, $38; racing camshaft, $69; racing-style solo saddle with large tool compartment, $95; four-pipe tuned exhaust system, $135; 1300cc engine rated at 1 10 bhp with 10.5:1 pistons and a sports camshaft for $356. With a few of the options you could wind up with a motorcycle costing around $6000 including air freight and U.S. import duty. It is the most expensive commercially produced motorcycle in the world.

A large firm in Germany has taken over the Munch factory and is expanding the facilities to increase motorcycle production. This will also lower production costs somewhat, but there will never be many Munch motorcycles around. Each one will be a classic.

Our day at Lions Drag Strip with the 1200 TTS went less well than we would have liked. A misfire crept into the engine each time we got into third gear, with some hesitation being noticeable in first and second gears. We can only surmise that a faulty fuel pump was causing what felt like fuel starvation. In fourth gear the misfire was so pronounced that we didn’t take any top speed readings, but have extended our graph with a dotted line up to the calculated top speed. Ordinarily we wouldn’t have made any runs at all with a test machine running less than perfect. But the Munch is a special machine in every sense of the word, and we had to give it a try.

Fierce standing starts with the Munch surprised us immensely. There was very little tire slippage and the clutch never slipped. The large machine just lunged forward in a straight line, gathering momentum rapidly. Although the clutch never slipped, it was necessary to adjust the cable after the fourth run. After the unit had cooled down, clutch adjustment could be returned to the normal position. Even with the distinct misfire we were able to turn the standing quarter-mile in 12.93 sec. with a terminal speed of 104.92 mph. What the times would be with the machine in proper tune we’ll leave to your imagination!

The Munch isn’t designed for the drag strip. It is intended to be the most powerful, awesome road burner ever built. There are plenty of people who are willing to pay the price to own such a bike. It’s easy to understand why.

View Full Issue

View Full Issue