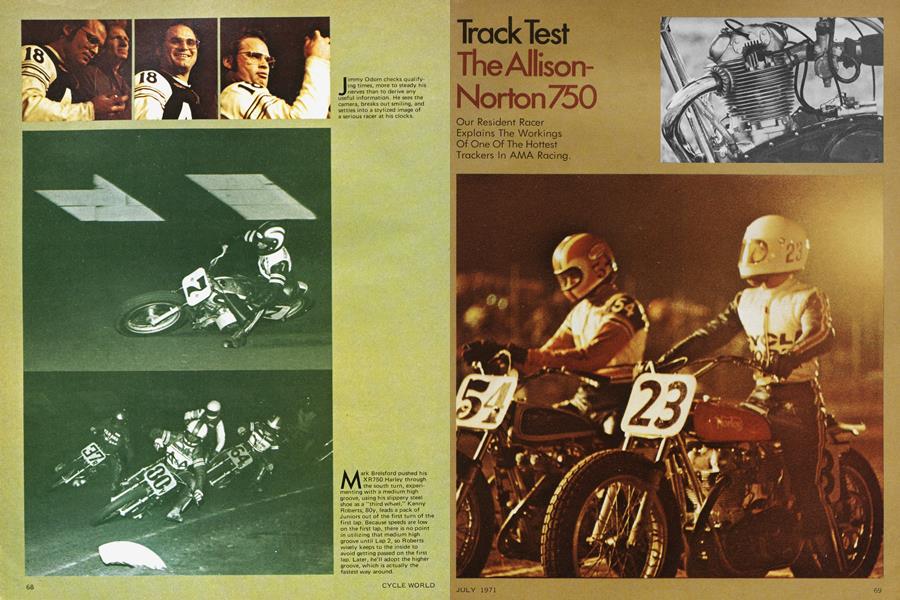

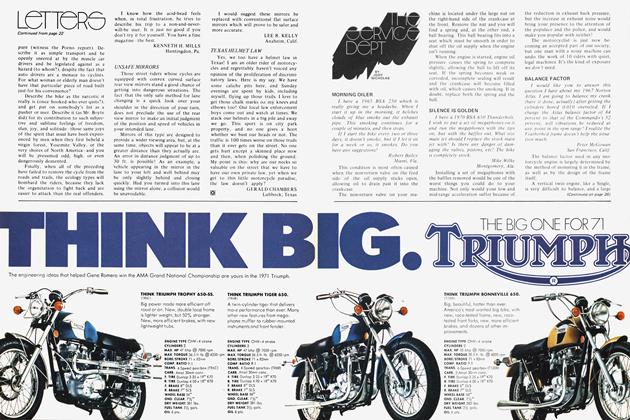

heAJ1isonNorton 750

Track Test

Our Resident Racer Explains The Workings Of One Of The Hottest Trackers In AMA Racing.

The Allison-Norton 750

JODV NICHOLAS

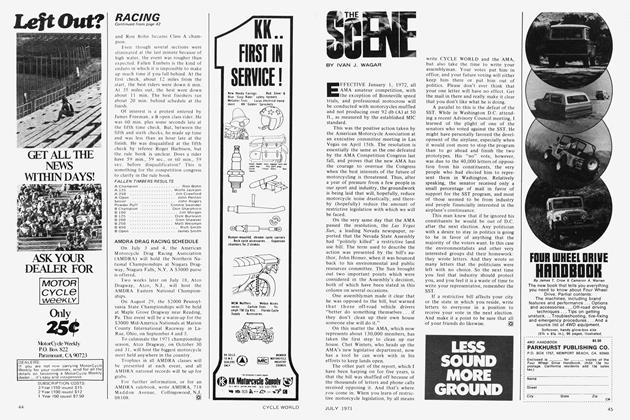

THE TYPICAL FLAT TRACKER is an amalgamation of various accessory manufacturers' bits and pieces. Calling a Triumph flat trackera iriuniph, for example. is like calling apples pears. It just ain’t so. Of course, the engine/transmission package is of Triumph design and manufacture, but little else on the machine is. Very few successful Triumph Hat trackers use Triumph frames, front forks or wheels, for example, although a few use racing gas tanks manufactured by Triumph. The same is true for BSA and Norton flat trackers.

Look closely at just about any flat tracker and you’ll find much the same situation: a proprietary manufacturer’s engine in someone else’s frame, using yet another maker’s forks and probably a third producer’s wheels. It’s also likely that none of the aforementioned companies made the gas tank or seat, either!

Until a few years ago, most Hat track machines were variations of a particular factory’s racing model. For example, BSA made its popular Gold Star available with a rigid frame and no brakes specifically for the American flat tracker. Triumph did the same with their T-100 model, and even Ariel marketed the Red Hunter 500-cc Single in dirt track guise. A few individuals campaigned Norton Twins in rigid frames, and several Royal Enfield and Velocette Singles made the headlines.

The Norton Commando 750 Twin makes an excellent engine for dirt track racing for a number of reasons. Its long stroke, medium speed engine is very powerful and reliable, spare parts are readily available and it’s just the right size, 750cc, the maximum displacement set by AMA rules. With a frame by Red Line Engineering, Ceriani forks. Koni shocks, Barnes wheels, and a great deal of Harold Allison’s ingenuity and hard work, this machine stands as a force to be reckoned with.

Although the combination must be in balance, the engine is perhaps the most important part of the motorcycle. True, the frame must be correctly designed and set up or all the horsepower in the world won’t help you. A broad, usable power band is a must, and the Norton has exactly that.

Inside the engine, a Norris cam is used in conjunction with Norris pushrods and valve springs. The special valves employed are shaped for maximum gas flow, and cylinder heads are flow tested and suitably modified. Special high compression Venolia pistons sit atop Careilo connecting rods, which are attached to a basically standard Commando crank. Carburetion is accomplished by two 30-mm Amal Monobloc instruments, the same size as used on the standard Commando. Larger carburetors and intake ports were tried some time ago. and although they produced slightly more top end horsepower, the mid-range punch so necessary for quick exits from the corners suffered.

In addition to being extremely fast, the Allison Norton is also very flexible. Power comes on in a predictable surge from low in the rpm scale and continues smoothly right up to maximum revs. It’s almost like turning an electrical rheostat.

In spite of this flexibility, the Norton develops an astonishing amount of peak horsepower. A trip to Lions drag strip to satisfy our curiosity yielded a standing one-eighth-mile run of 7.35 sec. with a terminal speed of 94.33 mph, and this was with the rear tire breaking loose for almost the entire distance! We also tried a quarter-mile run, but found that we didn’t have enough gearing to permit the machine to be held wide open through the traps. Thus, on the first run, we had to shut the throttle and coast through the traps at 87 mph with an elapsed time of 12.75 sec.

Given a powerful, flexible engine unit, the next step in construction, and the most difficult, is the frame and running gear. Cramming a Norton’s separate engine and transmission into the space normally occupied by a Triumph engine/transmission unit necessitated some judicious “shoehorning” and the making of new engine mounting plates. Special tabs were welded on to facilitate the mounting of an oil cooler, and an additional brace between the front frame downtubes was added as a safety measure. Linn Kastan of Red Line Engineering, who made the frame, was helpful in making the changes Harold requested.

All Red Line frames are fabricated from 4130 chrome-moly steel tubing which is heliarc welded and then normalized to relieve stresses. A nickel-plate finish makes an attractive, easy-to-clean frame. Front fork angle for the Red Line dirt track frame, with the bottom of the frame horizontal, is 26 degrees. A slightly less steep angle is used on a TT machine to aid stability, but the angle can be changed slightly by substituting longer or shorter rear shock absorbers for the desired effect. There doesn’t seem to be any one, magical formula to use in setting up a flat track or TT machine, but most of the successful British machines have dimensions similar to the Allison tracker.

Generally speaking, a 55-in. wheelbase seems to be ideal. Kastan’s frame is made so that the rear axle can be moved torward or back to get a range of wheelbase adjustment from 54.5 to 57 in. Also important is keeping the motorcycle’s center of gravity low to aid stability, but a problem arises when the engine is placed too near the ground, that of dragging the engine cases while leaned over in a turn. The height of the engine from the ground can be varied by substituting rear shocks of various lengths, and by moving the front forks up in the triple clamps.

Ceriani road racing fork legs are supported in Ceriani motocross pattern triple clamps to give a trail measurement of about 3.75 in., with the machine unladen. Raising or lowering the fork tubes in the triple clamps varies the amount of trail and the “quickness” of the machine’s steering, and also varies the length of the wheelbase, the height of the engine above the ground and the relative front fork rake angle.

Koni rear shock absorber units provide excellent action and adjustability. The Konis allow you to vary the spring rate with a twist ot the adjustment cam, and the rebound damping rate can be increased to compensate for wear of the shocks’ internals or to get a firmer ride for certain types of race tracks.

The position of the motorcycle’s seat is relatively limited by the design of the frame, but the rider can fit seats of differing thicknesses or lengths to suit his preference.

As a fiat tracker is designed to turn left only, the right footpeg may be mounted low and either forward or rearward to allow the rider to place much of his body weight where he wants it to alter the weight distribution of the motorcycle. The location of the left footpeg is relatively unimportant as long as it’s placed high enough to keep the rider’s foot from dragging the ground while cornering.

Footpeg placement and handlebars are very subjective. Some riders will only be able to do or feel well with one type of handlebar, bent in a certain way to make him most comfortable while cornering, or, in some cases, while motoring down the straightaway. Many riders bend their handlebars so that the left side is slightly higher than the right to allow them to sit more upright while cornering. A TT machine’s rider will generally have both sides of his handlebars the same height, however, because he has to turn both ways.

Handlebar fetishism is rife. Typical is the ever-popular Sammy Tanner, who started his fiat track career using low, practically straight handlebars. He stuck with this pattern for a number of years, and then suddenly switched to a set of tillers resembling the handles on a wheelbarrow! He just kept on winning.

Only within the past three or four years has the swinging arm frame become popular for dirt track racing. A few riders, notably Dick Mann and AÍ Gunter, had experimented with swinging arm frames on their Matchless G-50's as early as 1962, but their conclusions weren’t concrete enough, and their victories not conclusive enough, to make everybody want to rush out and buy one. The fact that none were being produced at that time also complicated matters. With a rigid frame, the rider had only to worry about the front end, because, with the exception of wheelbase length, the rear couldn’t be easily changed. Now the swinging arm frame for dirt track, as first produced in quantity by Trackmaster in 1968, is used almost universally. It’s a little more difficult to “tune” initially, but its adjustability more than offsets that disadvantage, and it is very little heavier than its rigid counterpart. When the tracks get rough and choppy, a “springer” is indispensable.

Once the chassis has been sorted out, the rider is faced with the problem of getting his power to the ground, which can be almost as difficult as setting up the chassis. Different types of tracks require different types of tires, and the changing track conditions at one race meeting may mean switching the tires several times.

First of all, the rider has to be able to “steer” the machine, which will call for a particular tread pattern. By careful analysis of the track, a tire can be decided upon, but the only sure way is to try it. If the track is loose or has a cushion surface, a rear tire with a good edge and a fairly open tread design will most likely prove adequate, whereas a groove or slippery track will call for a road pattern tire. Many tracks start the day being somewhat loose, and then tend to become hard and slippery, making it necessary for the rider to have a good supply of different tread patterns on hand. If the promoter passes over the track with a grader or scraper, you may have to go running for your tire tools.

The most popular types of tires in use today are the Pirelli Universal and the Dunlop K70, but Goodyear Grasshopper and Road Racer patterns are also used. Now and then, you’ll also see an Avon Speedway type, but they are pretty rare.

Flat track racing is easy to watch, but not everyone understands just what he's seeing. For the past couple of years, the flat track racer has had the option of using a rear wheel brake and/or downshifting, which can be used to advantage on groove tracks. But either of these techniques can get the rider into trouble if he doesn't understand how to use it. At certain tracks, cushions in particular, use of the brake is unnecessary, and will actualiy cause an increase in lap time. Jamming on the brake might also send another rider already committed to his slide right up your back!

A good cushion track is my favorite type, perhaps because it's easiest for me to ride. The Norton works well there. The thrill of blasting down the straight, rolling off the throttle and throwing the machine into a slide to slow it down is just about impossible to describe. The only thing I've ever done which is remotely similar is snow skiing, but my skiing experience is almost too limited to use as a parallel. The skier, like the flat track racer, uses his body and muscles to control his movement and attitude, and the dangers inherent are much the same.

When the motorcyclist has set up his slide, he has to concentrate on turning the machine and getting headed down the next straight. The speed through the corner is primarily controlled by the use of the throttle while in the slide. Too much throttle and the machine will tend to slide out from under you, and with too little throttle, speed will be lost and perhaps not enough turning effect will be produced.

Of course, not all the steering is done with the throttle, nor is it all accomplished by turning the handlebars. It’s rather a subtle combination of the two, augmented by the rider’s judgement in moving around on the seat to aid the transfer of weight to the rear wheel while coming out of a corner, or possibly to correct for hitting a bump or to change his line while in a turn.

Turning the front wheel inward to slow the machine is a trick used successfully by Bart Markei, Dick Dorrestyn and Jack O’Brien for reducing speed in a corner, but it is usually employed as a stopgap measure. Judicious use of the rear brake will produce the same effect with greater safety.

As with road racing, there is no “correct” line through a corner. Some riders prefer to stay down near the inside or “pole” and take the shortest way around, while others may elect to ride a higher groove at a faster speed. “Squaring” the turn may work for others, but I’m of the opinion that the rider must adjust his basic style to the track layout and condition. It sometimes becomes necessary to change lines in a turn to avoid a spill or pass a slower rider. As with other sports, it involves thinking ahead and expecting the unexpected. Quick, accurate analysis of a situation can preclude your falling off or losing valuable time.

Exiting a turn is considered by many to be more important than entering. It’s not as simple as turning the throttle as far as it will go, for wheelspin could result, costing valuable fractions of a second, while too much of a bite can force the rider to the outside edge of the track and into the fence. Excessive wheelspin can be lessened by moving the rider’s weight back, closing the throttle slightly, changing the air pressure in the rear tire or shortening the wheelbase slightly. It’s important for the rider to determine these things in practice, for shortening the wheelbase could cause the front wheel to “push” towards the outside of the track, and changing the air pressure could cause a loss of traction.

But the most flexible part of the combination is the rider himself. Once the machine is basically set up, the rider, by changing his angle of lean, position on the seat, or weight on the skidshoe, can do more towards getting around the race track fast than making subtle changes with a wrench here and there.

Allison

Norton 750

SPECIFICATIONS