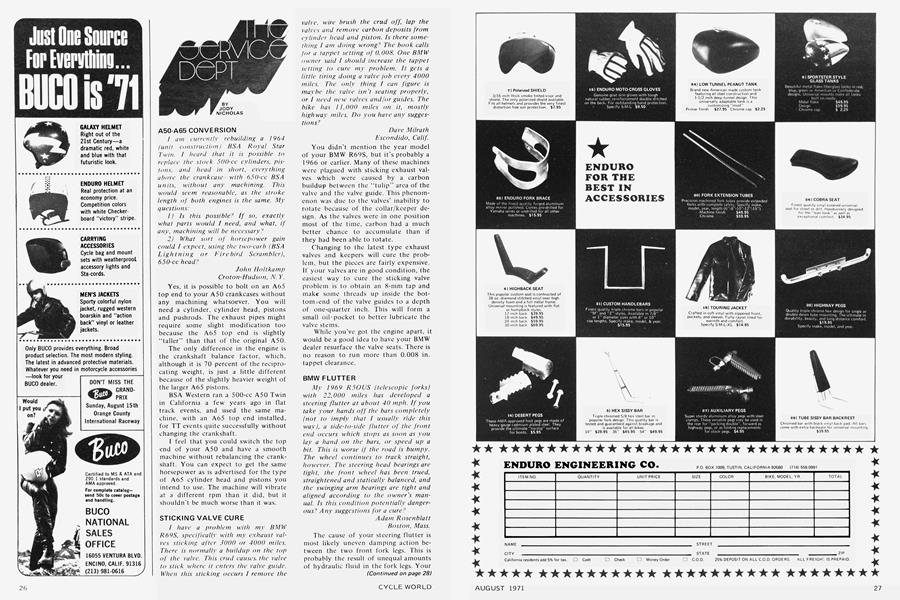

THE SERVICE DEPT

JODY NICHOLAS

A50-A65 CONVERSION

I am currently rebuilding a 1964 (unit construction) BSA Royal Star Twin. I heard that it is possible to replace the stock 500-cc cylinders, pistons, and head in short, everything above the crankcase—with 650-cc BSA units, without any machining. This would seem reasonable, as the stroke length of both engines is the same. My questions:

1) Is this possible? If so, exactly what parts would I need, and what, if any, machining will be necessary?

2) What sort of horsepower gain could I expect, using the two-curb (BSA Lightning or Firebird Scrambler), 650-cc head?

John Holtkamp Croton-Hudson, N. Y.

Yes, it is possible to bolt on an A65 top end to your A50 crankcases without any machining whatsoever. You will need a cylinder, cylinder head, pistons and pushrods. The exhaust pipes might require some slight modification too because the A65 top end is slightly “taller” than that of the original A50.

The only difference in the engine is the crankshaft balance factor, which, although it is 70 percent of the reciprocating weight, is just a little different because of the slightly heavier weight of the larger A65 pistons.

BSA Western ran a 500-cc A50 Twin in California a few years ago in flat track events, and used the same machine, with an A65 top end installed, for TT events quite successfully without changing the crankshaft.

1 feel that you could switch the top end of your A50 and have a smooth machine without rebalancing the crankshaft. You can expect to get the same horsepower as is advertised for the type of A65 cylinder head and pistons you intend to use. The machine will vibrate at a different rpm than it did, but it shouldn't be much worse than it was.

STICKING VALVE CURE

I have a problem with my BMW R69S, specifically with my exhaust valves sticking after 3000 or 4000 miles. There is normally a buildup on the top of the valve. This crud causes, the valve to stick where it enters the valve guide. When this sticking occurs / remove the valve, wire brush the crud off, lap the valves and remove carbon deposits from cylinder head and piston. Is there something I am doing wrong? The book calls for a tappet setting of 0.008. One BMW owner said I should increase the tappet setting to cure my pro blent. It gets a little tiring doing a valve job every 4000 miles. The only thing I ca/t figure is maybe the valve isn’t seating properly, or I need new valves and ¡or guides. The bike has 11,000 miles on it, mostly highway miles. Do you have any suggestions?

Dave Milrath Escondido, Calif.

You didn’t mention the year model of your BMW R69S, but it’s probably a 1966 or earlier. Many of these machines were plagued with sticking exhaust valves which were caused by a carbon buildup between the “tulip” area of the valve and the valve guide. This phenomenon was due to the valves’ inability to rotate because of the collar/keeper design. As the valves were in one position most of the time, carbon had a much better chance to accumulate than if they had been able to rotate.

Changing to the latest type exhaust valves and keepers will cure the problem. but the pieces are fairly expensive. If your valves are in good condition, the easiest way to cure the sticking valve problem is to obtain an 8-mm tap and make some threads up inside the bottom iend of the valve guides to a depth of one-quarter inch. This will form a small oil-pocket to better lubricate the valve stems.

While you’ve got the engine apart, it would be a good idea to have your BMW dealer resurface the valve seats. There is no reason to run more than 0.008 in. tappet clearance.

BMW FLUTTER

My 1969 R50US (telescopic forks) with 22,000 miles has developed a steering flutter at about 40 mph. If you take your hands off the bars completely (not to imply that I usually ride this way), a side-to-sidc flutter of the front end occurs which stops as soon as you lay a hand on the bars, or speed up a bit. This is worse if the road is bumpy. The wheel continues to track straight, however. The steering head bearings are tight, the front wheel has been trued, straightened and statically balanced, and the swinging arm bearings are tight and aligned according to the owner's manual. Is this condition potentially dangerous7 Any suggestions for a cure7

Adam Rosenblatt Boston, Mass.

The cause of your steering flutter is most likely uneven damping action between the two front fork legs. This is probably the result of unequal amounts of hydraulic fluid in the fork legs. Your machine is also fitted with a hydraulic steering damper unit, but these usually last almost indefinitely, and is probably not at fault. Unless the machine has been involved in an accident, the fork legs themselves won’t be at fault either.

(Continued on page 28)

Continued from page 26

Drain all the fluid out of the fork legs and compress the forks several times while the drain screws are out to completely clear them of fluid. Refit the drain screws and fill each fork leg with 9.5 oz. (280cc) of hydraulic shock oil (McKay shock oil, for example). If this doesn't cure the flutter, there is evidently a malfunction in one of the internal damper units, which should be rectified by a qualified BMW mechanic.

BATTERY ELIMINATOR

I have a 1970 Triumph 650. I have been considering mounting a custom seat on the bike, and removing the battery would make it much easier and cleaner looking.

I understand this particular model, a Trophy desert bike, is already wired for doing away with the battery.

Could you please explain the pros and cons of such a change, and tell me which system would be best for normal street and highway touring battery, magneto, or what7

Daniel Gryder San Diego, Calif.

Yes, it's true that you can run your 1970 Triumph Trophy without the battery, but to do so is illegal in California and in many other states too. State law requires that a vehicle’s lights (or at least the parking lights) be able to stay lit for 15 minutes after shutting off the engine. Obviously, there can be no lights without a source of power such as the generator or at least a battery.

If you are planning to do any offroad riding, or competition work, it would be beneficial to remove the battery and substitute in its place a Lucas capacitor and spring mounting. The Lucas capacitor (model 2MC’) carries a Lucas part number of 54170009 and is available at your Triumph dealer. The cost is very reasonable and installation instructions come with the unit.

The capacitor will allow you to use your lights, but only with the engine running. Because of its simple design and construction, the capacitor is very reliable, and has the advantage of being able to run the engine well, even if the alternator timing is not set perfectly. Electricity is stored inside the capacitor for several minutes, but it is not enough to run even the taillight. Another advantage of the capacitor is that it tends to reduce the d.c. voltage ripple, meaning longer light bulb life.