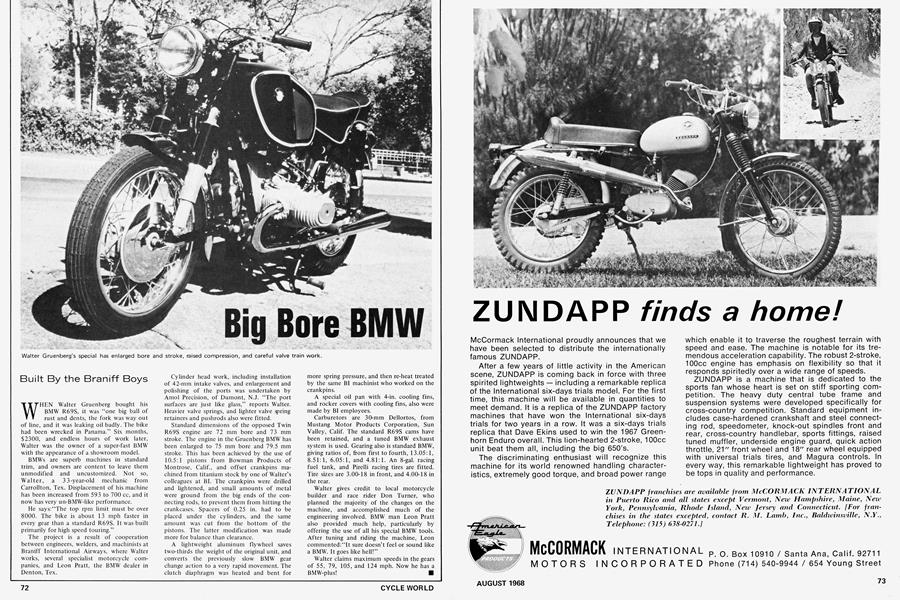

Big Bore BMW

Braniff Boys

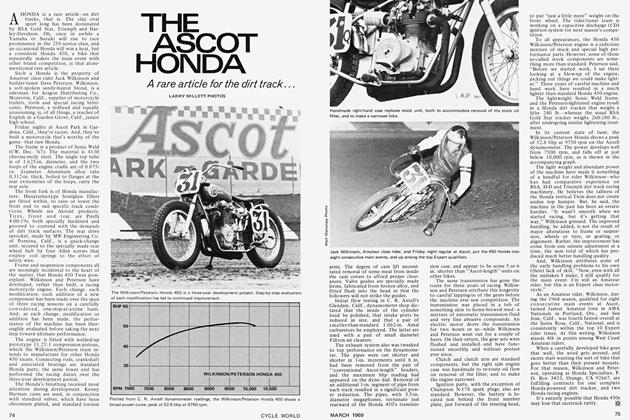

WHEN Walter Gruenberg bought his BMW R69S, it was "one big ball of rust and dents, the fork was way out of line, and it was leaking oil badly. The bike had been wrecked in Panama." Six months, $2300, and endless hours of work later, Walter was the owner of a super-fast BMW with the appearance of a showroom model.

BMWs are superb machines in standard trim, and owners are content to leave them unmodified and uncustomized. Not so, Walter, a 3 3-year-old mechanic from Carrollton, Tex. Displacement of his machine has been increased from 593 to 700 cc, and it now has very un-BMW-like performance.

He says:"The top rpm limit must be over 8000. The bike is about 13 mph faster in every gear than a standard R69S. It was built primarily for high speed touring."

The project is a result of cooperation between engineers, welders, and machinists at Braniff International Airways, where Walter works, several specialist motorcycle companies, and Leon Pratt, the BMW dealer in Denton, Tex.

Cylinder head work, including installation of 42-mm intake valves, and enlargement and polishing of the ports was undertaken by Amol Precision, of Dumont, N.J. "The port surfaces are just like glass," reports Walter. Heavier valve springs, and lighter valve spring retainers and pushrods also were fitted.

Standard dimensions of the opposed Twin R69S engine are 72 mm bore and 73 mm stroke. The engine in the Gruenberg BMW has been enlarged to 75 mm bore and 79.5 mm stroke. This has been achieved by the use of 10.5:1 pistons from Bowman Products of Montrose, Calif., and offset crankpins machined from titanium stock by one of Walter's colleagues at Bí. The crankpins were drilled and lightened, and small amounts of metal were ground from the big ends of the connecting rods, to prevent them from hitting the crankcases. Spacers of 0.25 in. had to be placed under the cylinders, and the same amount was cut from the bottom of the pistons. The latter modification was made more for balance than clearance.

A lightweight aluminum flywheel saves two-thirds the weight of the original unit, and converts the previously slow BMW gear change action to a very rapid movement. The clutch diaphragm was heated and bent for more spring pressure, and then re-heat treated by the same Bí machinist who worked on the crankpins.

A special oil pan with 4-in. cooling fins, and rocker covers with cooling fins, also were made by Bí employees.

Carburetors are 30-mm Dellortos, from Mustang Motor Products Corporation, Sun Valley, Calif. The standard R69S cams have been retained, and a tuned BMW exhaust system is used. Gearing also is standard BMW, giving ratios of, from first to fourth, 13.05:1, 8.51:1, 6.05:1, and 4.81:1. An 8-gal. racing fuel tank, and Pirelli racing tires are fitted. Tire sizes are 3.00-18 in front, and 4.00-18 in the rear.

Walter gives credit to local motorcycle builder and race rider Don Turner, who planned the majority of the changes on the machine, and accomplished much of the engineering involved. BMW man Leon Pratt also provided much help, particularly by offering the use of all his special BMW tools. After tuning and riding the machine, Leon commented:"It sure doesn't feel or sound like a BMW. It goes like hell!"

Walter claims maximum speeds in the gears of 55, 79, 105, and 124 mph. Now he has a BMW-plus! ■