THE SERVICE DEPARTMENT

GREAT ON RIGHTHANDERS

I purchased a 1965 CA-77 Honda Dream this spring which had been spilled last year, resulting in the front wheel being tipped to the right side of the fork assembly and the handlebars broken on one side. I replaced the bars and removed the front wheel and leading links to check damage.

If you are familiar with this machine, you will know that the links are connected with a tube that runs around the rear of the front wheel to add rigidity to the link assembly. This tube was twisted slightly and it was a simple matter to bend it straight. On reassembly, the wheel was now perfectly straight in the forks and everything functions normally. Close inspection reveals no other damage to the pressed steel forks or steering head and the wheel runs true.

On road testing, the machine appears to pull slightly to the right while riding slow or fast. I checked the wheel alignment and both wheels seem to be tracking okay.

Could this pulling be caused by the two front springs being uneven? The cycle was stored for several months with the front wheel tipped after the accident, causing one side spring to be compressed more than the other.

Douglas F. Holley North Bennington, Vt.

It would be well worthwhile removing the front suspension units, dismantling them and checking the spring rate. If one of the springs has taken a permanent set there will be an appreciable difference in the free length of the springs. Compare the free length of the springs with a new spring, if one is available. If possible, have the spring rate checked at the normal fitted length (length of spring when assembled on the damper unit). When checked at the normal fitted length, the load should be comparable for each spring, or the difference not more than 2 percent.

While the springs are removed, check that the damper units are working properly and that the damper rods are not bent. Hold the unit in a vertical plane and work the plunger rod up and down several times, noting any harshness or sticking. Also, check that the units are damping for the full length of their travel.

It may also be useful to replace the units (without springs) in the fork with the front wheel removed, and move the

fork up and down to ensure that there is no stiffness or binding caused by misaligned unit mounting points. Also, check this with the front wheel installed and the axle fully tightened. Make sure the front brake arms are straight and their mounting points are aligned.

MIXTURE ADJUSTMENT

I own a '67 Triumph TR6R and am having trouble with what I believe is carbur etion. Going along at any steady speed causes it to cut out very badly. It is especially bad when the tach is on a steady 2,600 rpm. During acceleration of any kind it runs fine. It is just when I level off to a steady speed. It has also been doing it at a steady 60 mph. It doesn't do it all of the time at high speeds, only after it has been running at, say 60 mph for a steady period of time. It then starts bucking quite badly.

Everything is as stock as it was when I bought it new. The timing and points have been checked twice and are okay. If there is any solution to this problem, I would appreciate your help.

Kenneth R. Klein Yuma, Arizona

The uneven running under conditions of part load may be caused by a rich mixture, and this could be caused by a poorly seating float chamber needle. Be fore attempting to do any carburetor ad justment, make sure that the needle seat is shutting off the fuel completely and is not leaking, causing a high fuel level in the float chamber. Slight leakage would not affect the performance of the machine when accelerating, but would cause erratic running when operating under light load (throttle only partially open). (Continued on page 24)

(Continued on page 22)

To check efficiency of the `needle seat ing, remove the needle seat body from the carburetor, turn it upside down, insert the needle and then pour a small quantity of fuel into the body aperture around the needle and check the seat for leakage.

Check that the main jet is the correct size by carrying out a "plug check." This can also be checked by partially closing the air valve when on full throttle; if the engine runs better, this would indicate that the main jet is too small (weak). Alterna tively, if the engine runs worse, the main jet is too large (rich).

Next, adjust the pilot air adjusting screw, first setting the throttle stop to obtain an even tick-over with the throttle closed. Back the pilot adjusting screw out two turns, then screw it in slowly until the engine starts to run erratically, then back it out approximately one-eighth of a turn or until the engine runs evenly again. Screwing the pilot screw in pro duces a rich idle and initial throttle open ing mixture; screwing it out will result in a weak mixture.

Check that the throttle valve has the correct cutaway. The throttle valve cut away will be stamped on the throttle valve. The last digit of the throttle valve number indicates the cutaway size. Example: a number 376/3 would indicate a number 3 throttle cutaway. A larger number would indicate a weaker mixture and a smaller number, which would be a 2 in this case, would be richer. The throttle valve cut away controls the mixture between the idle adjustment and the throttle needle position.

Check that the correct needle jet is fit ted, the number being stamped on the body of the jet. Also, check the needle position. Raising the needle will result in a richer mixture, and lowering it will pro duce a leaner mixture. The needle posi tion controls the mixture from one-quarter to three-quarter throttle.

Make sure that you are using the cor rect grade of spark plug. A spark plug that is too cold would tend to foul when operating at part load.

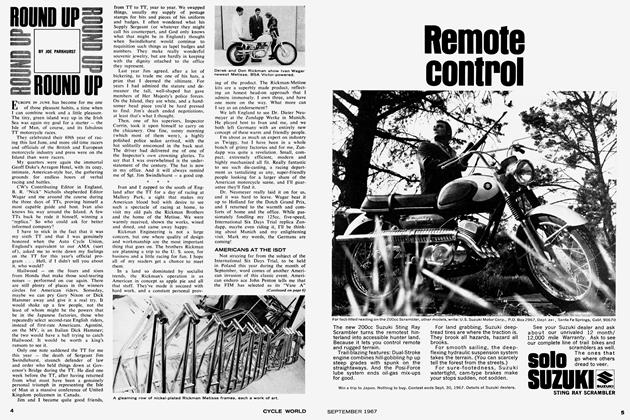

CON-ROD FAILURE

My Ducati 250 Diana Mark III shatter ed a rod with no warning knocks or rattles beforehand. It went out at 60 mph in fourth gear. I have no idea of the history of the bike, but it has an extra plug mounted directly opposite of the original plug. It is a very neat modification. I have no idea how they sparked the extra plug; but I know that by replacing the stock coil with a Honda 150cc twin lead coil it would be possible to spark the other plug. Will sparking two plugs cause the engine to overheat, and would it cause rod failure?

Roy Hughes ColleRedale. Tenn.

uii~geuuw, i rin. The connecting rod failure referred to would most likely be caused by a faulty forging, with the rod becoming cracked during the heat treatment process, or due to fatigue caused by long life, or by being overstressed due to excessive over-revving. Connecting rods have also been known to

fail due to severe detonation. The latter is most unlikely; if detonation had been occurring, the piston would show signs of severe damage at the crown, and it is also likely that the piston rings would be bro ken. Use of the twin plug head may have a bearing on this, although I very much doubt it. Theoretically, the twin plug ar rangement should improve combustion control and provide a shorter period of burning, particularly where high compres sion ratios are concerned.

With the second plug connected and both plugs being fired simultaneously, it may be necessary to retard the ignition timing a few degrees to obtain optimum spark. I would suggest trying this in stages of two degrees at a time. The twin plug head should not cause the engine to overheat.

HONDA BEARING CURE

In regard to your "Service Department" (June, 1967) article on the CB-77 with the seizure, there is an aluminum caged roller bearing on the outside right-hand crank shaft. This bearing rides directly on the crankshaft end and has no separate race. If the seizure did not damage the crank shaft end very badly, a ball bearing, No. C722902B (new number 91002-259-020) may be used as a replacement instead of revlacinR the crankshaft.

I ama mechanic at Gulf Coast Honda md Bultaco Sales. We have recently taken on Royal En field motorcycles. Coz4ld you tell me where I can get a dial indicator that will compensate for the 45-degree plug angle in the R-E? The dial indicator 1 have works fine in a vertical plug hole but is not accurate on the En fields. I owned an indicator awhile back that would adjust to the plug angle. I cannot remem ber where I bought it. Any information on where I could pur chase one would be greatly appreciated.

JohnW. Klaus Houston, Texas

Thanks for your interesting and helpful letter, John. I have made a few inquiries and have also had some letters from other Honda mechanics that indicate that the roller timing side main bearing quite often fails. As you have suggested, installing a ball bearing instead of the roller bearing often effects a permanent cure. Early C72 250cc Hondas were provided with a ball bearing on the timing side and ironically changed to the roller because of bearing failures.

I do not know of a dial indicator that will give accurate indications of piston p0sition when installed in an angled spark plug hole. In fact, I doubt that such a thing exists. However, if any reader knows where one can be obtained I will gladly pass on the information.

SKULL SESSION

After reading your reports on the 350 conversion for the Honda Hawk 305, 1 decided to make the conversion.

At the rime of the conversion, the bike had about 4,000 miles on it and ran per fectly. 1 installed the Webco 350 kit and Harman & Collins cams. I sent them my cylinders and they sent me the 350's in exchange.

The bike runs very well and I am quite pleased except for one detail. I have quite a large oil leak at the area of both spark plugs. 1 don't know if it is coming up from around the plug threads or from the groove where the piece for the plugs is pressed into the aluminum head. After running for an hour, I can remove the plugs and the threads are wet. Also, after this period of running there is oil all over the cooling fins and over the rest of the bike as it is blown back.

If I stop the machine and rev the engine, 1 can see smoke coming out from around the plugs. I am also blowing some smoke out of the mufflers.

When I was in Daytona I spoke to the people at the Webco booth and told them of this problem, and they said the head I had on the machine was faulty, and if I replaced it, that would solve the problem. Well, I went to the expense and put on a new head, but I still have the problem.

What I don't understand is that it didn't do this when it was a 305. I realize that a hole has been drilled from the oil gallery into the cylinder walls, and 1 guess this is where the oil is coming from. I have asked every dealer in the area for an answer, but they don't know.

Could you possibly tell me what is causing this and how to solve it? I now have 500 miles on the bike since I made the change to 350. If it was a small leak I wouldn't mind, but everything gets completely soaked with oil, so it is quite a large leak.

I would like to add that I have been breaking it in as follows: first gear, 15 mph; second gear, 30 mph; third gear, 45 mph and fourth gear, up to 60 mph. After how many miles should it be well broken in?

Stanley P. Sirkis Beltsville, Md.

On all the 250cc and 305cc range of Honda models, the cylinder heads are manufactured with a steel skull. The skull provides the combustion chamber portion of the cylinder head, a suitable material for the valve seats, and a durable spark plug boss. It is cast integrally with the head and is not removable. The only place that there is an outside joint between the steel skull and the aluminum head is where the spark plug bosses are situated.

It is not uncommon for oil from the cambox to seep between the skull and the head, causing an external leak at the spark plug boss. You have been very unlucky if you have had two heads with this same problem. However, before jumping to conclusions, it is best that you check the exact location of the leak.

Remove the spark plugs and thoroughly clean the area around the spark plug bosses with acetone or gasoline. Dry the area, replace the plugs, then start the engine and look for seepage. It may be necessary for the engine to be hot before any detectable leakage takes place. Leakage at the camshaft end cover gaskets will also result in oil running down into the area of the spark plug bosses.

It should only be necessary to break the pistons in for approximately 600 miles.

STRANGE NOISES

Is there a difference between "piston slap" and "piston rattle"?

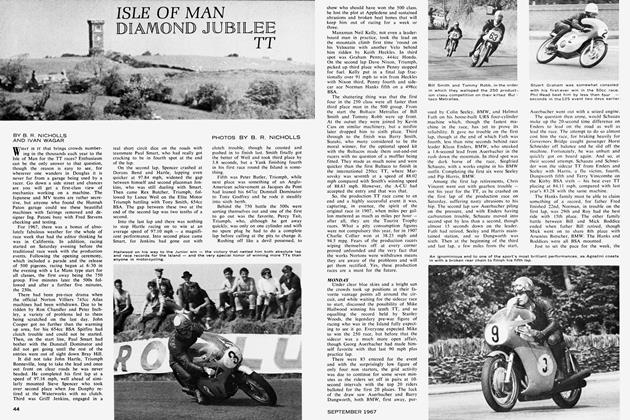

I have an AJS 500cc single. I recently took the engine apart and had the cylinder bored out to .040 over, and had a shop here in Denver fit a .040 oversize piston, with new rings. I also replaced the wrist pin and had the valves ground. The clearance between the bore and the piston measured about .007, which, I am told, is about correct.

I reassembled the engine, setting the valves correctly and timing the magneto and valve gears according to my AJS manual. I have about 15 miles on the engine now, and it sounds pretty healthy except for a rattling in it. Before 1 rebuilt it, it had a pronounced "knock." Could the rattle simply be one of the normal noises of a big single?

Dave Aitken Denver, Colo.

When in good condition, the AMC, AJS and Matchless, big singles are very quiet mechanically. The terms "piston slap" and "piston rattle" have the same meaning. They relate to the tapping or rattling noise usually heard when the engine is running under light load. The noise is more noticeable when the engine is cold. As the piston and cylinder warm up, the noise will diminish due to the higher expansion rate of the piston, which naturally reduces the piston skirt to cylinder wall clearance.

(Continued on page 26)

It is most unlikely that the knocking noise that you are experiencing with your machine is piston slap. When you installed the new piston and piston pin, what condition was the small end bush in? If this were worn, a tapping noise would be heard that is very similar to piston slap.

A common cause for knocking or tapping sound on large displacement AMC singles is often due to excessive end float on the exhaust and intake camshafts. The end float can be adjusted by tapping the camshaft bearings (that are situated in the timing case) in or out.

On an AJS equipped with a magneto, the end float of the exhaust camshaft can easily be checked by removing the magneto sprocket. (The magneto drive sprocket is fitted to the end of the exhaust camshaft that protrudes through the timing case cover.) With the aid of a dial indicator fitted to the end of the camshaft, the end float can be measured by pushing and pulling the shaft back and forth in the case. It is not so easy with the inlet camshaft, because it does not protrude through the timing case cover. This is best carried out when the engine is completely dismantled (timing side of crank case removed). The camshaft can be pushed back and forth from either end, and the end float checked.

OIL INJECTION

While at your recent CYCLE WORLD Show, I asked the Bridgestone representative whether the new 350 GTR had positive force injection to the bearings. He said no, and went on to explain that Bridgestone engineers had experimented with positive force, but had found that an oil spray into the intake port was superior to the direct injection.

My question is this: what would happen on a cold morning when the engine of a "spray" injected machine was started? Would not the cold, viscous oil have the tendency to merely ooze out of its aperture and dribble down the walls of the crankcase, or is the swirl effect so powerful that it tears the cold oil right in with itself? One more point; in what way can spray injection be superior to positive force?

Jay Miller

VictorviUe, Calif.

You bring up a very controversial subject when you delve into the pros and cons of providing adequate lubrication for a two-cycle engine employing crankcase compression. The Bridgestone representative would naturally favor the system they had adopted. Apart from anything else, it is a good sales point.

You refer to the possible disadvantages of the port-injected system under conditions of cold starting. All engines, including four-cycles, provide inadequate lubrication when starting from cold. Due to lack of instantaneous lubrication at all points when cold, a large percentage of the total wear takes place. This is why an engine should not be driven hard until normal operating temperatures have been attained. It is obvious that the oil will be less fluid when cold. There will, however, still be some accumulation of old oil in the crankcase to provide some lubrication initially. Even when the engine is hot, the oil will go' into the engine in the form of large droplets and will have to seek out the components requiring lubrication. As with a gasoline and oil mixture, there is nothing definite or guaranteed. Theoretically, and logically, a positively distributed supply to all critical components would be considered far superior. To carry this out fully would require a complex, finely metered system that would be expensive to produce and difficult to calibrate. Systems employing this principle have been used on some of the factory racing two-strokes. Some manufacturers have gone half way on their street machines. Suzuki positively lubricates the main and big end bearings and relies on splash for the piston and small end bearing. Yamaha employ port injection on their street machines, but on the TD1 production racers revert to a gasoline and oil mixture. They also advise customers who are preparing their machines for competition to dispense with the Auto-Lube system and use a gasoline oil mix.

As you can see, it is a very controversial subject. What works well on one design or application may not be adequate in another case. But port lubrication on rotary valve engines does ensure plenty of oil at the disc, where it is urgently required.

DIFFICULT TO DIAGNOSE

This is the second time I have written you in over three years. The first time was to commend you on your fine publication. Now I have a technical question which none of the motorcycle shops can help me with. 1 am hoping that you possibly might be able to.

(Continued on page 28)

Here it is, with some information first. The bike in question is a 1962 Triumph TR-6. I had the engine overhauled, balanced, Mondial 9-1/2 to 1 pistons, H&C is #6 intake and exhaust cams, "R" tappets with stock pushrods, Jomo valves and springs. I had a well-known shop (Burbank Triumph) weld aluminum Webco spigots onto my head and McEvoys shop in El Monte do some porting work on both intake and exhaust ports. The ports are the same size as my "376" Amal monoblocs, which are as parallel as possible (both have left-hand bowls). The bike starts fine and it feels like 1 have gained a lot of torque at all speed ranges.

The problem is this; at approximately 6,500 rpm the engine loses so much power that it feels like the brakes have been applied. It doesn't miss or sputter, it just makes a gasping sound and decelerates, but it's still running. I have had my magneto checked and know it isn't valve float, because I have taken it as high as 7,800 rpm with single carburetor and manifold before valve float set in. I have tried this many times in all gears and at 6,500 the power leaves abruptly. My compression readings are still 150 psi in each cylinder with no apparent damage done to the engine. I am now using:

Idle jets — 25 Needle jets — 107 Main jets — 320

Needle position — Third Notch

I am still getting lean plug readings and I thought this is a rich set-up on jet sizes for the small A mals.

1 know I should have had the head flowbench tested, but didn't know anything about it at the time. Does it sound like tuning problems or seizure? Any information will be greatly appreciated. I am willing to spend money to correct this problem and gain back some precious rpm.

I have always used megaphones, but since the exhaust port work, the bike is very loud. 1 don't want to offend anyone and I don't need any tickets. Will stock Triumph mufflers hinder me at all?

John C sa ft is

North Hollywood, Calif.

The type of trouble being experienced with your machine is usually the most difficult to diagnose — even when visual inspection is possible. I suggest that you first check out the fuel supply system, making sure that the feed lines provide sufficient flow capacity. Preferably, you should use two fuel taps, providing a separate line to each carburetor. The internal bore of both line and tap should be at least 1/4 inch diameter. Make sure that the carburetors are mounted vertically when viewed from the rear. If they were canted, this would affect the float chamber fuel level.

How thoroughly was the magneto checked? To ensure that the unit was functioning properly, it would have to be checked for both electrical and mechanical malfunctions. To achieve this it would be necessary for it to be motored up to full speed on an adequately equipped test bench. Even a simple thing like a sticking contact arm pivot may not cause any problems at low speed, but could fail completely at a higher operating speed.

(Continued on page 30)

Is your machine equipped with a magneto cutout button, located on the handlebar or possibly on a frame member beneath the seat? If so, it is possible that due to vibration at the critical engine speed a short is occurring, causing the magneto to cut out. Check the wiring to make sure that the insulation is in order, and check the internals of the cutout button. Or, better still disconnect the cutout wire at the magneto and then test the bike.

You state that there was no problem with a manifold and single carburetor. I therefore assume that the trouble started after the intake spigots were installed and welded into the head. If this is the case, it is quite possible that on reassembly all the parts did not go back the same. A sticking valve or a broken valve spring may be causing the trouble.

What grade of spark plug are you using? If the spark plug were too hot for your engine, this would result in overheating of the spark plug, which would give an indication similar to a weak mixture when taking plug readings. When a spark plug reaches a critical temperature, it fails to operate. It may be necessary to go to a colder spark plug.

Forget about using megaphones or open pipes on the street; the standard Triumph mufflers are very good and will not give you any performance problems.

If you feel that you do not have sufficient know-how to cure the problem, take your machine to an old established Triumph dealer, preferably one that specializes in preparing competition machines.

TO THE DELIGHT OF ONLOOKERS

I own a Honda CB160 with 7,000 miles. I am now in the process of installing Super Hawk foot controls. I have removed the electric starter to reduce the weight and have been using the kick starter, and now, with the installation of the rear controls, that can no longer be used either. Besides the inconvenience, how much damage can be done to the clutch or transmission by push starting? Is there any other method of starting besides putting the electric starter back on?

Thomas Wendt Barrington, 111.

Push or bump starting will not cause damage to the clutch or transmission. However, as mentioned by you, it is most inconvenient, particularly if the machine has stalled in the middle of a busy intersection. Not only can it be inconvenient to push-start in a crowded situation, it can be very dangerous. I would suggest that you reinstall the electric starter. The added weight will not make a noticeable difference to the performance of the machine. There is no other convenient method of starting that I know of. ■