THE SERVICE DEPARTMENT

GARY BRAY

A GOOD QUESTION

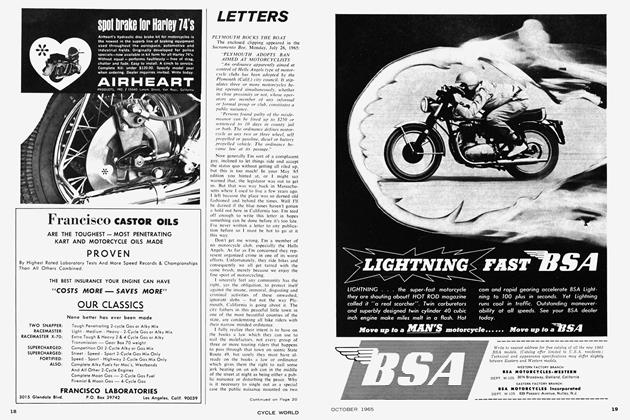

For several years I rode and enjoyed a BSA 650. Now, a year after selling it I realize how much fun I'm missing so I'll get another motorcycle as soon as I can.

I'm still impressed with BSA hut now I find they’ve turned their gearbox upside down. After five years of “up for 1st” I’m afraid force of habit might, in some emergency, have me shifting the wrong way. Of course, there are other machines with the "right” shift pattern and I'll eventually decide what I want.

My question then is why are there so many different shift patterns in cycle gearboxes (in cars with four gears I believe only the location of reverse is not "standard”) and specifically, why did BSA change?

A. T. Charlesworth San Diego, Calif.

Why arc there so many different gear shift patterns on different motorcycles? Probably because each manufacturer feels his is the right way and why worry, let the buyer figure it out. Up to this point, growth of the motorcycle industry has been pretty haphazard. The manufacturers' seeming inability to hear the mutterings of riders, dealers and distributor's, at least in this country, may have created the gulf.

Maybe a roar directed across the Atlantic will help. Specifically, why did BSA change their gearbox design? Since BSA and Triumph are mergered companies and Triumph had already developed a transmission for their unit construction machine, why spend the money to engineer a different gearbox for the unit BSA?

This is known as taking a short cut. If this practice is followed throughout development and manufacture of a product, the end result should he less cost per motorcycle, giving the manufacturer a greater profit. That is, unless he reduces the price of the motorcycle accordingly. This would make the buyer happy. However, at this time there are many very happy manufacturers.

IT'S A SOMETIME THING

/ own a 1957 Indian Blazer 700ec. It will only run on one cylinder (right). I have cheeked the plugs and plug cables and caps. 1 have also cleaned the mag completely. The points are new and 1 cheeked the timing unit and the springs. Everything seems to he fine, but It still runs on one cylinder. At high revs the left cylinder will sometimes fire. I would like any help you can give me.

Leon ./. Rollins Miami, Florida

You have checked the three areas in an ignition system that most commonly cause this sort of trouble. However, a more positive method of determining if a spark plug is at fault is to switch plugs. Try the left hand plug in the right cylinder. Spark plug testing equipment can be misleading since conditions under which the plug must function in an engine cannot be duplicated in the standard plug testing machine.

Spark plug caps can cause grief, particularly if they are plastic. A crack in the cap. not visible to the naked eye. or a coating of dust inside the plug cover is often the culprit. If the plastic plug covers are being used, I would suggest replacing them with the rubber cover type. Magnetos are reasonably trouble-free, but an occasional difficulty arises in the high-tension cable pickup. These are also plastic and can fail if they become cracked.

Lack of compression is a possible cause for an inoperative cylinder, but unless damage to the valves or piston is quite serious, complete failure of the cylinder to function is unlikely, at least at high rpms.

Continued on Page 32

continued

AN EARLY CUB

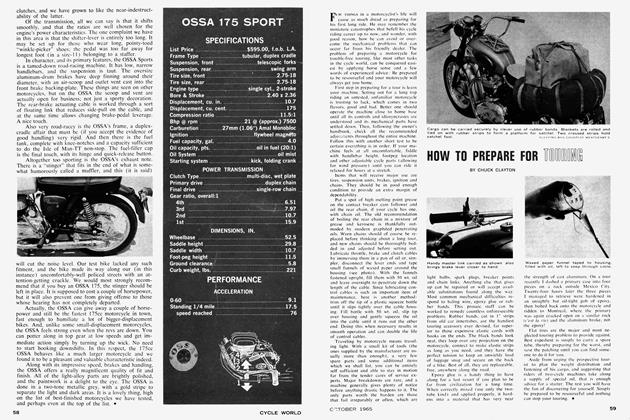

I am (he owner of a ’56 Triumph Cub T-20. As you know, the earlier Cubs utilized the single row chain primary drive. 1 am wondering if it is possible to install the later cub duplex chain primary drive sprockets in my bike. Would this be a simple bolt-on operation or would it require any special machining?

There is this terrible pounding and thrashing in the engine which is most predominate at low rpms. 1 have a new crankshaft assembly and main bearing in the bike at present. Upon inspection of the piston, I found the skirts were melted and it had over .007 clearance at the top and over .010 clearance at the bottom of the bore. 1 have since determined that it was running too lean, thus causing the melted skirts and scorched piston dome. However. could this excess of clearance along with bad rings cause the thrashing?

I am planning to bore to .060 from the existing .040 to correct the excess of clearance. I will be using a Hepolite piston with 10.5-1 compression. Undoubtedly this will upset the engine balance even further. Could you advise me on the proper procedure of balancing this new arrangement?

Randall Perkins

Pearl City, Hawaii

The duplex primary drive assembly can be installed on your Í956 Tiger Cub. Special machine work will not be required. It does appear, however, that the duplex chain will not stand as much abuse as the single row type, and chain failure has been frequent, at least in competition machines.

Excessive piston clearance such as you describe will very definitely cause engine noise. The maximum piston clearance for your machine is .005. The factory balance of this motorcycle has proven satisfactory for most uses and it is unlikely that the replacement piston will be that much heavier than the original, thereby affecting the balance to any noticeable degree.

Before assembling the machine, weigh the new piston. If it is 100 grams heavier than the old one (or more), rebalancing should be considered. Balancing procedure is a rather detailed process and would require more space than is available in this column. I would recommend the book Motorcycle Engineering by P. E. Irving, which has a good section on this subject.

LET’S STRESS IT

This letter is not really intended as one of complaint but more as one of information which you may or may not find of value. Perhaps you are already quite aware of what I am about to say but I have never seen anything in your magazine which would indicate you are conscious of it or want it stressed — therefore this letter.

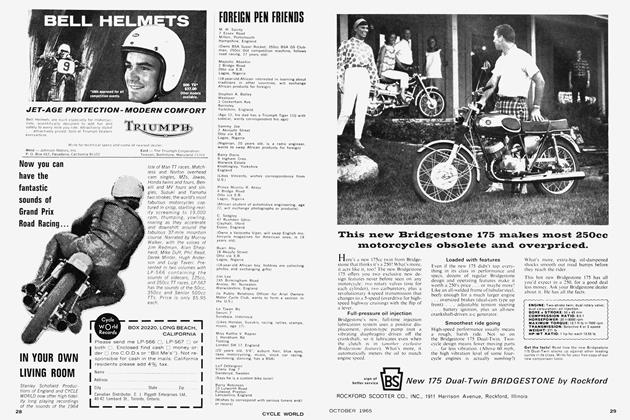

Recently my wife and 1 completed a trip through the Southwest of over 2000 miles on a Norton 750 which had 1600 miles on the odometer before leaving. Prior to departure the machine urn carefully checked and made ready. Enroute it was ridden conservatively and carefully maintained but a great many annoying mechanical shortcomings became evident. They began when the machine was accidentally pushed off its stand and fell on the right side, breaking the fulcrum on the front brake lever (understandable damage). However, I noticed this part is apparently made of brass. A strange material to use for such a critical item as a front brake control on a motorcycle. Later the same day the rear brake locked several times in heavy traffic (putting us in a fine pickle). Later the clutch cable required adjustment which 1 did and in a couple of days it was slack again. There is now no more room for adjustment. The cable has stretched so much it will have, to be replaced. To continue: the transmission is now making ugly noises, the rear chain is totally worn out (1 see a wider rear chain is used on the latest models). Aren’t such items tested before release to the market? All the rubber used on the machine, with the exception of the tires is in the last stages of decomposition, one of the throttle slides jammed wide open (not while riding, fortunately), and the primary chaincase leaks oil, and no wonder, considering the design of the seal.

1 realize motorcycles require frequent adjustment and tinkering but some of this is going too far in what is supposed to be a quality machine. 1 don’t have a great knowledge of other makes of motorcycles but it seems a safe bet they are no more dependable for the most part. Cer tainly the Norton appears to be at least as well constructed as any other machine. 1 bought it new after a great deal of reading about and comparison with other makes but it seems my research has come to nothing. Do I have a lemon or is atu; motorcycle this undependable? Perhaps other readers would like to see how different makes hold up after they are ridden longer than just what is required for a road test.

James Marchand

Santa Rosa, Calif.

Yes, Virginia, there are problems. Poor quality control, design mistakes, insufficient testing and an attitude on the part of many European motorcycle manufacturers that flaws do not exist in their products, have made motorcycling a rather frustrating experience for many people.

Reasons for this condition existing in the motorcycle industry today are varied and complex, but the basic difficulty lies with some manufacturers' all-to-conservative attitude in gearing their factories to meet the ever-increasing demand — and the motorcycle industry is growing. For a mechanical conveyance designed to transport man, it seems a shame that progress has been so slow. Especially when the motorcycle came before the airplane or automobile.

Troubles that a rider may encounter with a new machine are oftentimes due to human error during assembly, or just plain bad luck. In the case of your clutch cable needing frequent adjustment, along with a suddenly noisy transmission, I would suspect that one of the two gearbox mainshaft nuts was working loose.

Be of stout heart; töday’s problems will be cured on next year’s models. •