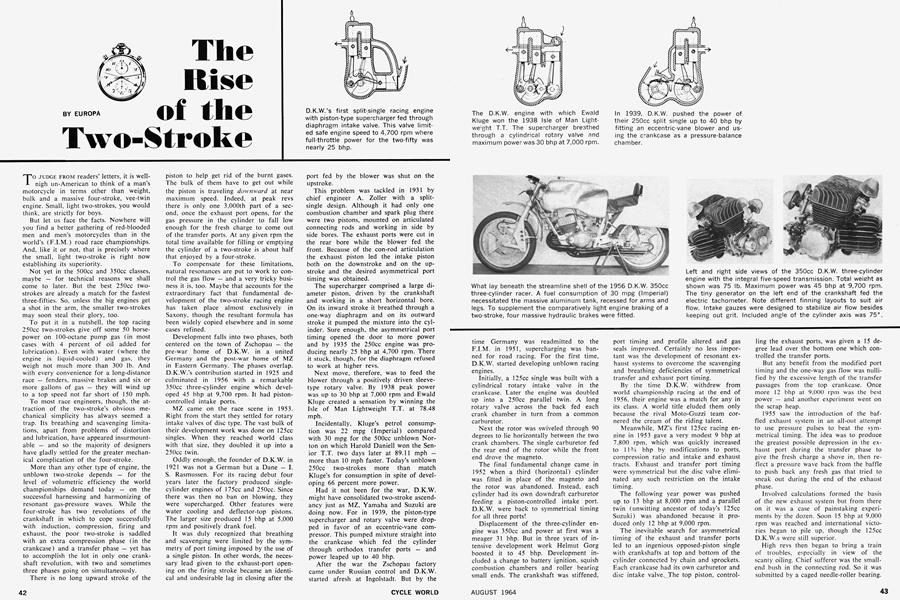

The Rise of the Two-Stroke

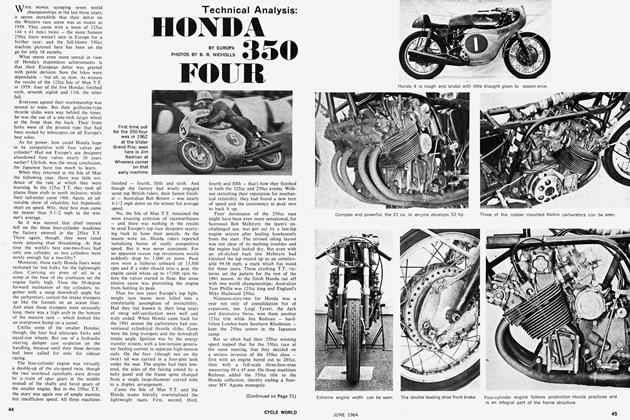

EUROPA

To JUDGE FROM readers' letters, it is well-nigh un-American to think of a man's motorcycle in terms other than weight, bulk and a massive four-stroke, vee-twin engine. Small, light two-strokes, you would think, are strictly for boys.

But let us face the facts. Nowhere will you find a better gathering of red-blooded men and men's motorcycles than in the world's (F.I.M.) road race championships. And, like it or not, that is precisely where the small, light two-stroke is right now establishing its superiority.

Not yet in the 500cc and 350cc classes, maybe — for technical reasons we shall come to later. But the best 250cc twostrokes are already a match for the fastest three-fifties. So, unless the big engines get a shot in the arm, the smaller two-strokes may soon steal their glory, too.

To put it in a nutshell, the top racing 250cc two-strokes give off some 50 horsepower on 100-octane pump gas (in most cases with 4 percent of oil added for lubrication). Even with water (where the engine is liquid-cooled) and gas, they weigh not much more than 300 lb. And with every convenience for a long-distance race — fenders, massive brakes and six or more gallons of gas — they will wind up to a top speed not far short of 150 mph.

To most race engineers, though, the attraction of the two-stroke's obvious mechanical simplicity has always seemed a trap. Its breathing and scavenging limitations, apart from problems of distortion and lubrication, have appeared insurmountable — and so the majority of designers have gladly settled for the greater mechanical complication of the four-stroke.

More than any other type of engine, the unblown two-stroke depends for the level of volumetric efficiency the world championships demand today on the successful harnessing and harmonizing of resonant gas-pressure waves. While the four-stroke has two revolutions of the crankshaft in which to cope successfully with induction, compression, firing and exhaust, the poor two-stroke is saddled with an extra compression phase (in the crankcase) and a transfer phase yet has to accomplish the lot in only one crankshaft revolution, with two and sometimes three phases going on simultaneously.

There is no long upward stroke of the piston to help get rid of the burnt gases. The bulk of them have to get out while the piston is traveling downward at near maximum speed. Indeed, at peak revs there is only one 3,000th part of a second, once the exhaust port opens, for the gas pressure in the cylinder to fall low enough for the fresh charge to come out of the transfer ports. At any given rpm the total time available for filling or emptying the cylinder of a two-stroke is about half that enjoyed by a four-stroke.

To compensate for these limitations, natural resonances are put to work to control the gas flow — and a very tricky business it is, too. Maybe that accounts for the extraordinary fact that fundamental development of the two-stroke racing engine has taken place almost exclusively in Saxony, though the resultant formula has been widely copied elsewhere and in some cases refined.

Development falls into two phases, both centered on the town of Zschopau the pre-war home of D.K.W, in a united Germany and the post-war home of MZ in Eastern Germany. The phases overlap. D.K.W.'s contribution started in 1925 and culminated in 1956 with a remarkable 350cc three-cylinder engine which developed 45 bhp at 9,700 rpm. It had pistoncontrolled intake ports.

MZ came on the race scene in 1953. Right from the start they settled for rotary intake valves of disc type. The vast bulk of their development work was done on 125cc singles. When they reached world class with that size, they doubled it up into a 250cc twin.

Oddly enough, the founder of D.K.W, in 1921 was not a German but a Dane — I. S. Rasmussen. For its racing debut four years later the factory produced singlecylinder engines of 175cc and 250cc. Since there was then no ban on blowing, they were supercharged. Other features were water cooling and deflector-top pistons. The larger size produced 15 bhp at 5,000 rpm and positively drank fuel.

It was duly recognized that breathing and scavenging were limited by the symmetry of port timing imposed by the use of a single piston. In other words, the necessary lead given to the exhaust-port opening on the firing stroke became an identical and undesirable lag in closing after the port fed by the blower was shut on the upstroke.

This problem was tackled in 1931 by chief engineer A. Zoller with a splitsingle design. Although it had only one combustion chamber and spark plug there were two pistons, mounted on articulated connecting rods and working in side by side bores. The exhaust ports were cut in the rear bore while the blower fed the front. Because of the con-rod articulation the exhaust piston led the intake piston both on the downstroke and on the upstroke and the desired asymmetrical port timing was obtained.

The supercharger comprised a large diameter piston, driven by the crankshaft and working in a short horizontal bore. On its inward stroke it breathed through a one-way diaphragm and on its outward stroke it pumped the mixture into the cylinder. Sure enough, the asymmetrical port timing opened the door to more power and by 1935 the 250cc engine was producing nearly 25 bhp at 4,700 rpm. There it stuck, though, for the diaphragm refused to work at higher revs.

Next move, therefore, was to feed the blower through a positively driven sleevetype rotary valve. By 1938 peak power was up to 30 bhp at 7,000 rpm and Ewald Kluge created a sensation by winning the Isle of Man Lightweight T.T. at 78.48 mph.

Incidentally, Kluge's petrol consumption was 22 mpg (Imperial) compared with 30 mpg for the 500cc unblown Norton on which Harold Daniell won the Senior T.T. two days later at 89.11 mph more than 10 mph faster. Today's unblown 250cc two-strokes more than match Kluge's for consumption in spite of developing 66 percent more power.

Had it not been for the war, D.K.W. might have consolidated two-stroke ascendancy just as MZ, Yamaha and Suzuki are doing now. For in 1939, the piston-type supercharger and rotary valve were dropped in favor of an eccentric-vane compressor. This pumped mixture straight into the crankcase which fed the cylinder through orthodox transfer ports and power leaped up to 40 bhp.

After the war the Zschopau factory came under Russian control and D.K.W. started afresh at Ingolstadt. But by the time Germany was readmitted to the F.I.M. in 1951, supercharging was banned for road racing. For the first time, D.K.W. started developing unblown racing engines.

Initially, a 125cc single was built with a cylindrical rotary intake valve in the crankcase. Later the engine was doubled up into a 250cc parallel twin. A long rotary valve across the back fed each crank chamber in turn from a common carburetor.

Next the rotor was swiveled through 90 degrees to lie horizontally between the two crank chambers. The single carburetor fed the rear end of the rotor while the front end drove the magneto.

The final fundamental change came in 1952 when a third (horizontal) cylinder was fitted in place of the magneto and the rotor was abandoned. Instead, each cylinder had its own downdraft carburetor feeding a piston-controlled intake port. D.K.W. were back to symmetrical timing for all three ports!

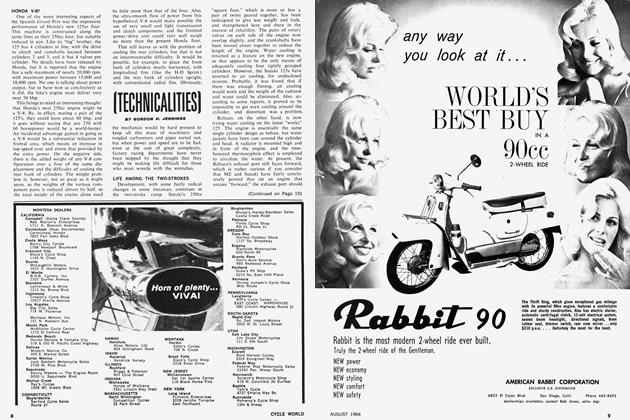

Displacement of the three-cylinder engine was 350cc and power at first was a meager 31 bhp. But in three years of intensive development work Helmut Gorg boosted it to 45 bhp. Development included a change to battery ignition, squish combustion chambers and roller bearing small ends. The crankshaft was stiffened, port timing and profile altered and gas seals improved. Certainly no less important was the development of resonant exhaust systems to overcome the scavenging and breathing deficiencies of symmetrical transfer and exhaust port timing.

By the time D.K.W. withdrew from world championship racing at the end of 1956, their engine was a match for any in its class. A world title eluded them only because the rival Moto-Guzzi team cornered the cream of the riding talent.

Meanwhile, MZ's first 125cc racing engine in 1953 gave a very modest 9 bhp at 7,800 rpm, which was quickly increased to 1134 bhp by modifications to ports, compression ratio and intake and exhaust tracts. Exhaust and transfer port timing were symmetrical but the disc valve eliminated any such restriction on the intake timing.

The following year power was pushed up to 13 bhp at 8,000 rpm and a parallel twin (unwitting ancestor of today's 125cc Suzuki) was abandoned because it produced only 12 bhp at 9,000 rpm.

The inevitable search for asymmetrical timing of the exhaust and transfer ports led to an ingenious opposed-piston single with crankshafts at top and bottom of the cylinder connected by chain and sprockets. Each crankcase had its own carburetor and disc intake valve._The top piston, controlling the exhaust ports, was given a 15 degree lead over the bottom one which controlled the transfer ports.

But any benefit from the modified port timing and the one-way gas flow was nullified by the excessive length of the transfer passages from the top crankcase. Once more 12 bhp at 9,000 rpm was the best power — and another experiment went on the scrap heap.

1955 saw the introduction of the baffled exhaust system in an all-out attempt to use pressure pulses to beat the symmetrical timing. The idea was to produce the greatest possible depression in the exhaust port during the transfer phase to give the fresh charge a shove in, then reflect a pressure wave back from the baffle to push back any fresh gas that tried to sneak out during the end of the exhaust phase.

Involved calculations formed the basis of the new exhaust system but from there on it was a case of painstaking experiments by the dozen. Soon 15 bhp at 9,000 rpm was reached and international victories began to pile up, though the 125cc D.K.W.s were still superior.

High revs then began to bring a train of troubles, especially in view of the scanty oiling. Chief sufferer was the smallend bush in the connecting rod. So it was submitted by a caged needle-roller bearing.

Main bearings were strengthened and bigend rollers lightened. Battery ignition was adopted because of magneto failures. By the end of the year another Wi bhp and 200 rpm had been put on the power peak.

To give the big end a cooler time the cylinder was laid horizontal in 1956 and the intake disc switched through 90 degrees to the top rear of the crankcase. It was driven by skew gears and it fed the charge straight between the flywheel cheeks. But power dropped to 14 bhp, piston seizures were frequent and the skew gears gave trouble.

So it was back to the side disc layout and concentrate on development. Some concentration, too, for today's one-twofive produces 21V2 bhp at 11,600 rpm. By the time the power peak had climbed to 10,000 rpm even the needle-roller littleend bearing had had enough. To cool it a third transfer port was cut, plumb opposite the exhaust port, and fed through a window high in the piston skirt. In that way some of the cool fresh charge was blown over the little-end bearing during the transfer phase. To the factory's joy, the third transfer port not only solved the little-end problem, it also gave a bonus of 1 Vi bhp.

Next the contact breaker took on the role of Achilles heel. So its speed was halved and two sets of contact points used. Later on, batteries were abandoned in favor of rotating-magnet magnetos. A forward-facing exhaust port was tried but it took the edge off acceleration. With the port at the rear, piston thrust on that wall of the cylinder improves the gas seal between crankcase and exhaust system.

From 20 horsepower upward (160 bhp per litre) it was found that engines became increasingly individualistic. Primary and secondary compression ratios, disc timing, port profiles and piston window width may vary from engine to engine. Attempting to copy a particularly good engine precisely is usually a waste of time. On average, however, the intake port opens 40 degrees after bottom dead center and closes 65 degrees afier top dead center. Total exhaust period is 175 degrees and transfer 125 degrees. Thus the exhaust port has a 25 degree lead and lag. Ignition advance is just under 1/8-in. Crankcase compression ratio is about 1 Vi to 1 and secondary 16 to 1.

Doubling up the 125cc single into a 250cc parallel twin, with a carburetor at each side and the crankshafts coupled to a common drive gear in the middle was an obvious move. MZ and Yamaha still adhere to this pattern for 250cc. But it was Suzuki who exploited the advantages of even smaller cylinders with their 125cc twin and challenging 250cc square four.

The clue to this line of development came with the introduction of the 50cc class in 1962. Single-cylinder engines of that size proved to be far more reliable and less temperamental than those of 125cc despite spending so much more time flat out. Hence the 125cc twin and the doubling up of that into a square four.

It is this need for very small cylinders that at present prevents the two-stroke from seriously invading the 500cc and 350cc classes. Because of the rotary valves, the cylinders can be coupled no more than two abreast. A 500cc eight or a 350cc six would obviously be too long to install in a road-racing solo. Already the Suzuki four is an embarrassingly bulky engine. So even if Yamaha or MZ doubled-up a 250cc twin to make a 500cc four, they would never get it into a road-race frame.

Since MZ established the basic formula seven years ago — disc intake valve, three transfer ports, half-moon squish cylinder head and resonant exhaust system — progress has been through refinements such as water cooling, ignition improvements, exhaust tuning and Yamaha's auxiliary oiling, rather than through fundamental changes. It will be interesting to see whether the racing two-stroke has anything to gain from direct fuel injection or electronic ignition.

Both supercharged and otherwise, the two-stroke started off by scaring away most designers and development engineers. Now, as with D.K.W. in 1939, the dedicated perseverance of a handful of wizards has made the type thoroughly competitive. Only an unlikely restriction imposed on fuel consumption could set it back now.