THE SERVICE DEPARTMENT

GARY BRAY

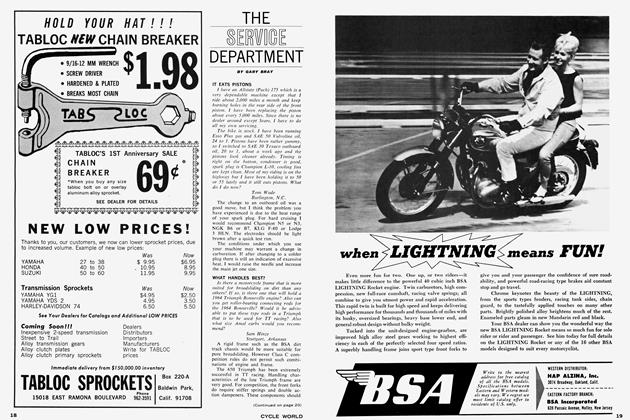

HE'D RATHER SWITCH

Can a 1964 BSA engine be installed in a 1957 frame without an excessive amount of adaptations? Both engine and frame are 650cc size. L. Baker Dallas, Texas

Owing to completely different engine designs, installation of a 1964 unit construction BSA power plant would require complete relocation of the engine mounts along with removal of the rear engine and gearbox mount used on the earlier frame.

In practically all instances where a change of this sort is desired, too many problems are encountered to make such an installation worth while. Engines arc designed for particular frames, and vice versa.

PING

/ have a 1957 BSA Road Rocket. The engine was rebuilt recently and high-compression pistons were installed (lOVz to I ). I use high test gasoline hat the engine insists on “pinging” whenever I accelerate. / have tried raising the needle in the carburetor and this stops most of the pinging, hut the engine runs very rough at idle and seems to load up when I go over 60 mph. At anything above 65 mph the engine stops altogether until / let go of the throttle, then it comes in with a surge of power. I have tried lowering the needle one or tw’o notches hut the pinging only gets worse. The intake manifold has not been touched and the carh is a standard Ama! Monohloc. What is causing this floodingout of the engine and how can it he fixed without having to listen to the engine pinging all the time?

Kent R. Groth

Syracuse, AT.Y.

These engines had a spark lead of 13/32 B.T.D.C. which causes no problem when the compression ratio does not exceed 9 to 1. Reducing the ignition timing to 11/32 B.T.D.C. should alleviate the problem.

Excessive oil in the combustion chambers will also cause the same pinging, it has been found that oil rings of this type ^ are not as efficient as they should be in this particular engine. If there appears to be an excessive oiling condition, an oil ring of this type may have to be used

An increase in compression should réduire an increase in the main jet of at least one size. The needle should be raised, but probably no more than one notch. If this carburetor has a #3 Vi slide, a #3 slide might correct the dead spot you feel as the throttle is turned on. The low speed (pilot) jet may require a change from .20 to .25.

If, after making these carburetion changes (and they should be made one at a time), the ping has gotten worse, go in the other direction: for example, from a #3Vi slide to a #4 slide.

AH SO, NO START

/ have a 1964 SOcc Yamaha that wall not run (or start). 1 was ill recently and the cycle has not started since.

As spark, fuel, carh all appear ok, must he the intake rotary valve disc?? Hope you can tell me the best procedure to replace the disc. Do they break or fail often?

Charles Helvie Kokomo, Indiana

Your machine having been inactive for a time, the carburetor may have become coated with residue from evaporated fuel. If the carburetor has not already been cleaned, it can be done very simply. With the carburetor off the machine, remove the float bowl and various rubber seals. If carburetor or parts cleaner is not available, lacquer thinner can be used. Soak the parts thoroughly and blow out all passages with an air hose.

The rotary valve is practically troublefree. About the only thing that can cause a problem is water in the fuel, which will swell the fiber disc. In a few instances the pin which positions the rotary disc may shear, but the engine will usually still make some attempt to run. Procedure for replacing the rotary valve is as follows: Drain transmission oil. Detach panel covering carburetor. Remove carburetor and clutch case. The nut holding the crankshaft drive gear must now be removed. When the nut and gear are off (no special puller is required) the cast iron housing containing the rotary valve can be removed. There are six screws affixing this housing to the crankcase.

(Continued on page 14)

Once the housing is off, it is a simple task to slip the rotary valve off the crankshaft. The rotary disc will only fit properly one way. so timing should be no problem. Remember to refill the transmission with oil when the machine has been reassembled.

V-8 AND G-50 QUESTIONS

/ really enjoyed the article on the Moto-G nzzi V-8. Could / have more information on it. including how fast it goes (top speed), how much they cost, if they still are producing them?

How much does a Matchless G-50 cost and where can you buy them?

Fred Huddleston Littleton, Colorado

The Moto-Guzzi V-8 reached speeds close to 170 mph with a fairing. This machine was not produced for sale to the general public and the one pictured in the September. 1964 article is the only one of its kind. Unfortunately, the Matchless G-50 is no longer being manufactured. Its list price when new was $1.550.00. At least twenty-five G-50s were imported into the U.S.. but finding even a used one. especially one for sale, would be difficult.

WHERE HAS THE PERFORMANCE GONE?

/ have a Yamaha YA5 I25cc which has 4.000 miles on it. The problem is that over the last few months a steady decline has developed in engine output and speed. Is it possible that it needs a de-carbon job or is there another solution? Also, what effect does an altitude of 5,000 feet have on a two-stroke engine?

Mike Cravens Reno, Nevada

Excessive carbon in the exhaust port could be cutting down the performance of your machine. I would suggest doing a complete tune-up along with the de-carbonizing job. This should include checking the ignition timing. Correct timing is 2.0mm B.T.D.C. Ignition timing is very important to good performance in this type of engine and should be checked at least every 1.000 miles. An increase in altitude will cause a loss of power. This can be remedied somewhat by fitting the carburetor with leaner jets.

BLOW OUTS

/ have no answer to the ouest ion people sometimes ask, “What would you do if the front tire blew out?” Does any company make a steel cord tire or a tire-witliin-atire arrangement. or a blow oat-proof tire for t veles/ If so. bow does one get in touch with them?

(Continued on page 16)

lom DeWitt

Tunkhannock, Pa.

Most tires manufactured for use on motorcycles have steel cord in the beads of the tire. Í here are not. to my knowledge. any tires produced which are “blowout-proof” (or use a double inner tube) that can be used on a motorcycle wheel rim. I he possibility of a blowout, even under hard usage, is at worst remote. The high quality of tires available to riders today, plus the light weight of modern machines and slower rotating speed of the wheels compared to an automobile, make tire failure not impossible, but very improbable. So don’t worry.

As to what to do if this should ever happen. one must remain calm above all. Quick movement or application of the brakes will usually hasten disaster. Above 35 or 40 mph. control is not too difficult to maintain. Below a certain speed you'll have your hands full. Get a good grip on the bars, shift your weight to the other wheel and decelerate carefully.

REDUCING VIBRATION

Could you please tell me if any improvement could be made to an XL Sportster by dynamically balancing the engine and dutch assembly/ Do you have any other suggestions as to reducing the vibration/ The motorcycle is being used as a road touring machine.

Harold Rogers

Saskatoon, Saskatchewan Rebalancing the lower end will certainly help, although there is-bound to be a vibration point somewhere in the engine’s RPM range, in most cases the balance percentage could be higher than the factory uses. The V-twin type of power unit seems to have this problem more than other designs. If vibration is excessive, some time spent examining the running gear for such causes as looseness in the steering head bearings, broken or loose engine mounts, too much play in the swinging arm, or a broken or cracked frame may prove more effective and less costly than dismantling and rebalancing. Excess play in the front fork bushings can also cause vibration, as will wheels that are not in balance. If you rebalance the engine, be sure to check the balance of the clutch assembly. You might find out quite a lot about what’s causing the problem.

HARD ON WHAT?

Re October I h64 CYCLF. WORFD, “Intelligent Motorcycling, Part 2," an excellent article that us newcomers to the sport can really appreciate. One small comment: page 27. middle column, “Most experienced riders will downshift through all the gears . . . This saves brakes, etc.” / disagree! This downshifting is very hard on transmission and engine, especially the transmission. Transmission repairs are very expensive compared to the cost of replacing brake linings. Furthermore, if “defensive” driving is done there should be no need for the additional braking power the engine compression gives.

Henry Frey ni k Oakland, California

I agree wholeheartedly with the defensive driving bit. but that downshifting is very hard on engine and transmission I cannot go along with. Granted a certain amount of common sense and skill is involved in downshifting. One could not approach a stop at 60 mph, shift into low, drop the clutch and not experience some strain somewhere down below (plus a rather hectic landing).

When done correctly, however, downshifting can contribute to a smooth, controlled ride. Skillful downshifting places no more strain on the machinery than shifting up. In the years I have been riding motorcycles (14 to be exact) I remember only one case of gearbox failure and it wasn't attributable to downshifting.

Having the right gear engaged for sudden acceleration, should it ever be necessary, is a part of defensive driving, too.

PUCH HOP-UP

Anyone wishing to obtain information for increasing the performance of the Puch or Allstate 60cc Scrambler may write Mike Laakko, 1156 N. Vernon, Dearborn 7, Mich. 48128.