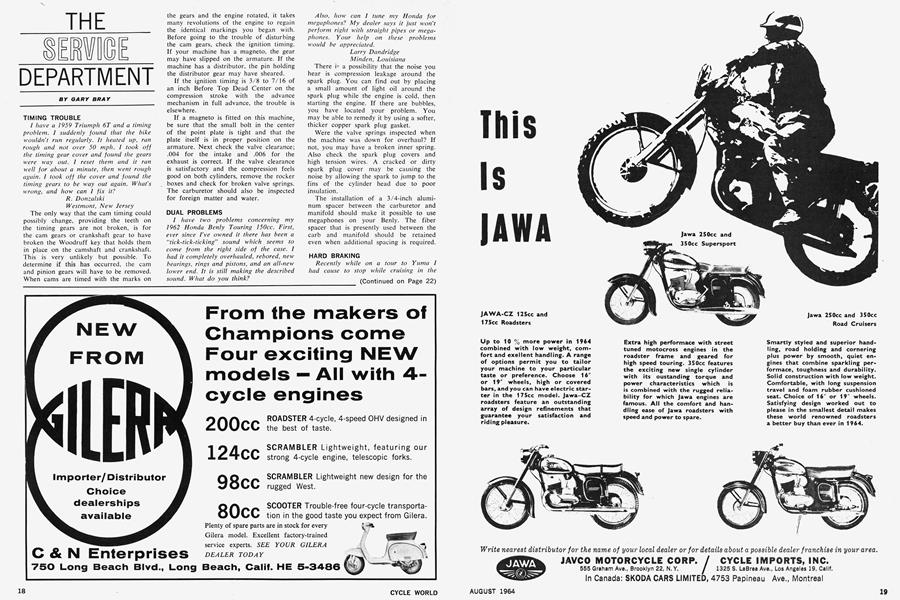

THE SERVICE DEPARTMENT

GARY BRAY

TIMING TROUBLE

I have a 1959 Triumph 6T and a timing problem. I suddenly found that the bike wouldn't run regularly. It heated up, ran rough and not over 50 mph. I took off the timing gear cover and found the gears were way out. I reset them and it ran well for about a minute, then went rough again. I took off the cover and found the timing gears to be way out again. What's wrong, and how can I fix it?

R. Donzalski West mont, New Jersey The only way that the cam timing could possibly change, providing the teeth on the timing gears are not broken, is for the cam gears or crankshaft gear to have broken the Woodruff key that holds them in place on the camshaft and crankshaft. This is very unlikely but possible. To determine if this has occurred, the cam and pinion gears will have to be removed. When cams are timed with the marks on the gears and the engine rotated, it takes many revolutions of the engine to regain the identical markings you began with. Before going to the trouble of disturbing the cam gears, check the ignition timing. If your machine has a magneto, the gear may have slipped on the armature. If the machine has a distributor, the pin holding the distributor gear may have sheared.

If the ignition timing is 3/8 to 7/16 of an inch Before Top Dead Center on the compression stroke with the advance mechanism in full advance, the trouble is elsewhere.

If a magneto is fitted on this machine, be sure that the small bolt in the center of the point plate is tight and that the plate itself is in proper position on the armature. Next check the valve clearance; .004 for the intake and .006 for the exhaust is correct. If the valve clearance is satisfactory and the compression feels good on both cylinders, remove the rocker boxes and check for broken valve springs. The carburetor should also be inspected for foreign matter and water.

DUAL PROBLEMS

ƒ have two problems concerning my 1962 Honda Benly Touring 150cc. First, ever since I've owned it there has been a "tick-tick-ticking" sound which seems to come from the right side of the case. I had it completely overhauled, rebored, new bearings, rings and pistons, and an all-new lower end. It is still making the described sound. What do you think?

Also, how can 1 tune my Honda for megaphones? My dealer says it just won't perform right with straight pipes or megaphones. Your help on these problems would be appreciated.

Larry Dandridge Minden, Louisiana

There ic a possibility that the noise you hear is compression leakage around the spark plug. You can find out by placing a small amount of light oil around the spark plug while the engine is cold, then starting the engine. If there are bubbles, you have located your problem. You may be able to remedy it by using a softer, thicker copper spark plug gasket.

Were the valve springs inspected when the machine was down for overhaul? If not, you may have a broken inner spring. Also check the spark plug covers and high tension wires. A cracked or dirty spark plug cover may be causing the noise by allowing the spark to jump to the fins of the cylinder head due to poor insulation.

The installation of a 3/4-inch aluminum spacer between the carburetor and manifold should make it possible to use megaphones on your Benly. The fiber spacer that is presently used between the carb and manifold should be retained even when additional spacing is required.

HARD BRAKING

Recently while on a tour to Yuma 1 had cause to stop while cruising in the 70's. Both brakes were applied at the same time, with vigor, while back-shifting. My trouble was an uncontrollable roll from side to side; in desperation I accelerated. This corrected the wobble and with hick I got out of a tight spot. I would like to know what caused the roll? And what if anything can be done to correct this if it were to happen again?

(Continued on Page 22)

John Renner El Segundo, Calif.

The undesirable effect from hard braking was due to loss of traction. It could be caused by any one of several things — braking to the point of a skid; sand, dirt or gravel on the road; and possibly grease or oil on the highway which is very hard to detect until you pick yourself up and go back and look.

You evidently did the right thing by accelerating. In the future if this problem is encountered I can think of nothing other than to get back on that throttle. A little more attention to what's going on a quarter of a mile or so up the road when you are traveling at speed will keep the possibility of a panic stop down to a minimum.

STOP THAT LEAK

I have a small oil leak on my 1956 500cc Indian Tomahawk, coming from between the cylinders or just below them in the center of the crankcase housing. Do you have any idea what is causing this leak and how I can stop it?

J. C. Proctor

Chapel Hill, No. Carolina

It may very well be that the cylinder base gaskets will have to be replaced. Crankcase leakage at this point is also a possibility, due to the fact that the intake camshaft passageway is located at this point, and a rather large quantity of oil supplied to the cams. There are three nuts behind the camshaft sprockets, two behind the intake cam and one behind the exhaust. These nuts must be tight; if they are not, crankcase leakage will occur. To tighten these nuts, the timing cover will have to be removed and in all probability the cam sprockets themselves. It may be possible to alter an end wrench to tighten these nuts without disturbing the cam sprockets and chain, however.

A MAICO TIP

For the Maico rider who desires a stiffer suspension, Zundapp Super Sabre shock absorbers can be fitted in place of the stock Maico shocks. The Zundapp shocks are lighter in weight and are adjustable for either hard or soft ride. In making this change, the Maico shock bushings may be used in conjunction with Zundapp rubber grommets. These grommets, however, will have to be trimmed slightly to allow them to fit in their respective mounts. I own a Jawa 250, the same type tested in the July 1962 issue of CYCLE WORLD. Ás the Jawa is rated at 12 bhp, it is barred from use on freeways. Is there any way 1 can increase the horsepower to meet the legal requirements for freeway travel? George E. Fogerson San Mateo, California Regardless of any increase in horsepower, the Motor Vehicle Department of California goes only by the horsepower rating listed by the manufacturer.

CABLE TROUBLE?

Cable failure, particularly clutch cable failure, can usually be traced to lack of lubrication. The ball end of the clutch and brake cables should rotate freely in the lever. If the cable ends become dry, this causes a slight binding which in turn breaks the cable. A few drops of engine oil once every two weeks, at the ball end and the lever hinge, will increase cable life.

STRANGE KNOCK

I own a 1956 BS A 650cc twin. 1 overhauled it about 4,000 miles ago, including new piston, new rod and main bearings, crankshaft ground and cleaned out, and a valve job. I let it run in at low speeds, but the first time 1 took it up to around 50 mph 1 noticed a slight knock. It seems to occur between 45 and 60 mph when the machine is under no load and not decelerating. At anything over 40 mph, if the throttle is closed and then opened, you can hear the noise just as the throttle begins to open. How can 1 determine what it is?

B. J. Hasten

Barstow, Calif.

The first thing to check is the possibility of a loose exhaust pipe. It may be that one of the pipes is moving back and forth in the cylinder head and causing the noise. There is also a chance that your machine has suffered valve spring failure. While inspecting the top end, be sure to check the rocker arm shafts; they have been known to break on this particular machine.

Many times excessive piston clearance can be the culprit. If BSA replacement pistons were used, no more than .003 clearance should be necessary for normal use. Other brands of replacement pistons may require slightly more clearance, but not more than .005, and they will probably rattle when the engine is cold.

The probability of trouble in the lower end is slight, if the rods were properly set up. The timing side bushing should have .0015 to .002 clearance, and it is a good practice to replace the rod bolts when one of these machines has a major overhaul. If the knock is not found in the top end, and becomes worse, then obviously the lower will have to be inspected. If the engine is dismantled again and everything appears to be correct and in its proper place, I would have that crankshaft magnafluxed.

FREEWAY TROUBLE

(Continued on Page 24)

The solution to your problem is certainly not an easy one. You have one of four choices: you can forego the pleasures (?) of freeway travel; ride the freeways anyhow, constantly looking over your shoulder for the little boys in blue; get the manufacturer to change his listed horsepower rating; or replace your present machine with one that has a more optimistic horsepower rating. You are certainly not going to change any of the policies of that grand institution, the California Motor Vehicle Dept.

ACID

Are you bothered by 'acid spill-over from your battery? Get a plastic sack, a little larger than the battery. Place the battery inside, fold the sack over on top and hold it in place with a rubber band or narrow piece of old inner tube. Remember to cut away a place in the sack for the battery terminals.

On early Lucas and batteries of that type, a small opening should be left around one of the terminals to allow the battery to breathe. Some of the later types will require a small plastic tube inserted through the sack near the top and taped in place. Covering the battery in this manner makes servicing a little more difficult but acid damage to paint and chrome will be held to a minimum.

CARBURETOR CHANGE

/ own a 1952 AJS twin and would like to replace the early type A mal carburetor with a late Monobloc. What size Monobloc should I use? What about main jet size and needle position?

William R. Frauenpries Pittsburgh, Penna.

You can replace your old style Amal with a 1-1/16" Monobloc. This carburetor should be quite satisfactory and only a slight modification of the manifold will be necessary to match the two.

You should probably use the middle notch on the needle, and the same main jet size as the old Amal. As there are no iron-clad rules as to carburetor settings, you may find it necessary to use richer or leaner settings depending on your location and brands of gasoline.

STRIPPED THREADS

Reader Bill Newbauer of Garrett, Indiana sent along the following quick method of saving stripped spark plug threads. First, the hole is probably close enough to 9/16" so that it can easily be enlarged to a full 9/16" with a reamer. The reamer won't "grab" like a drill and there is no danger involved. Tap with a 3/8" pipe and insert threaded end of pipe after sawing from two sides to within 1/4" so that the pipe will break off at this point. Spotface top down to aluminum with at least a 1" counterbore, suitable pilot, then drill or ream pipe to 1/2" and tap 14mm for plug. With this method the plug isn't pulling a "coil" out but is actually a seal against the head and pipe.

View Full Issue

View Full Issue