(TECHNICALITIES)

GORDON H. JENNINGS

HONDA V-8?

One of the more interesting aspects of the Spanish Grand Prix was the impressive performance of Honda's new 125cc four. This machine is constructed along the same lines as their 250cc four, but suitably reduced in size. Like its "big" brother, the 125 has 4 cylinders in line, with the drive to clutch and camshafts located between cylinders 2 and 3, and it has 4 valves per cylinder. No details have been released by Honda, but it is reported that the engine has a safe maximum of nearly 20,000 rpm, with maximum power between 15,000 and 18,000 rpm. No one is talking about power output, but to have won as conclusively as it did, the bike's engine must deliver very near 30 bhp.

This brings to mind an'interesting thought: that Honda's next 250cc engine might be a V-8. By, in effect, mating a pair of the 125's, they could have about 60 bhp, and it goes without saying that any 250 with 60 horsepower would be a world-beater. An incidental advantage gained in going to a V-8 would be a substantial reduction in frontal area, which means an increase in top speed over and above that provided by the extra power. On the negative side, there is the added weight of any V-8 configuration over a four of the same displacement and the difficulty of cooling the rear bank of cylinders. The weight problem is, however, not so great as it might seem, as the weights of the various component parts is reduced almost by half, so the total weight of the engine alone need be little more than that of the four. Also, the ultra-smooth flow of power from this hypothetical V-8 would make possible the use of very small and light transmission and clutch components, and the finished power/drive unit could very well weigh no more than the present Honda four.

That still leaves us with the problem of cooling the rear cylinders, but that is not an insurmountable difficulty. It would be possible, for example, to place the front bank of cylinders nearly horizontal, with longitudinal fins (like the H-D Sprint) and the rear bank of cylinders upright, with conventional radial fins. Obviously, the mechanics would be hard pressed to keep all this mass of machinery and tangled carburetors and pipes sorted out, but when power and speed are to be had, even at the cost of great complexity, factory racing departments have never been stopped by the thought that they might be making life difficult for those who must wrestle with the wrenches.

LIFE AMONG THE TWO-STROKES

Development, with some fairly radical changes in some instances, continues in the two-stroke camp. Suzuki's 250cc "square four," which is more or less a pair of twins geared together, has been redesigned to give less weight and bulk, and strengthened here and there in the interest of reliability. The pairs of rotary valves on each side of the engine now overlap slightly, and the crankshafts have been moved closer together to reduce the length of the engine. Water cooling is retained as a feature on the new engine, as that appears to be the only means of adequately cooling four tightly grouped cylinders. However, the Suzuki 125s have reverted to air cooling, for undisclosed reasons. Probably, it was found that if there was enough finning, air cooling would work and the weight of the radiator and water could be eliminated. Also, according to some reports, it proved to be impossible to get even cooling around the cylinder, and distortion was a problem.

Bultaco, on the other hand, is now trying water cooling on the latest "works" 125. The engine is essentially the same single cylinder design as before, but water jackets have been cast around the cylinder and head. A radiator is mounted high and in front of the engine, and the timehonored thermosyphon effect is employed to circulate the water. At present, the Bultaco's exhaust port still faces forward, which is rather curious if you consider that MZ and Suzuki have fairly conclusively proved that on an engine that rotates "forward," the exhaust port should be around on the back of the cylinder. This is done because the angularity of the connecting rod during the power stroke tends to press the piston against the rear of the cylinder, and better piston sealing results — which gives a slight but worthwhile increase in power.

(Continued on Page 10)

Yet another change in the works Bultaco that is worth mention is the new frame, which is a double-loop affair, made of steel tubing, that follows quite closely the pattern set by Norton's Manx. This bit of copying places Bultaco among good company, because all of the factory road racing bikes seem to be going to the Manx-type frame these days. Actually, it is about time someone started a new trend in frame design. Virtually all of the present motorcycle frames are made up of curved tubes and must, as a result, be heavier than is strictly necessary. A steel tube is most efficient when it is absolutely straight, and loaded only in tension, torsion and compression. It does not handle beam loads very well, and if it is curved, it will not have much resistance against tension and compression loads. Thus, the strongest frame, for any given weight, would be one in which all tubes were straight, and loaded only at the ends of the tubes. This would be difficult to achieve with most contemporary engines, which are made to be cradle-mounted, but it is by no means impossible and this offers an opportunity to save a few pounds in an area that has been rather neglected for many years.

IGNITIONS

We can expect to see a lot of new developments in ignition systems through the 1964 racing season — particularly in the two-strokes. The two-strokes no longer seem to have much trouble with fouled plugs, which is a tribute of no small proportions to the wizardry of the spark plug manufacturers, and even piston seizures are becoming less common, byt recently there has been a rash of ignition system bothers. This is not because the systems themselves have gotten worse; the demands on the systems are simply much greater. An extreme example is afforded by the Suzuki four, which at maximum revs requires a fantastic 50,000 sparks per minute. To create a system that will do the job at all is a remarkable technical achievement, and to get complete reliability as well may take some time.

The task will be easier if those building racing ignition systems will take advantage of recent advances in electronics. We are fast approaching the limit of effectiveness for the traditional breaker point system, and it is time to move on to the transistor. Bultaco is experimenting with this, and it would seem that the transistorized system would solve a lot of problems. By placing a small magnet in a crank-driven disc, and then locating a pick-up coil next to the disc we can have a timed "signal" that will take the place of conventional breaker points. The small pip of electricity from this pick-up coil has to be amplified before it has sufficient strength to control the transister which "valves" current to the ignition coil, but a small, light mercury cell will provide all the current needed for the amplifier and power for the coil can be generated by a flywheel alternator, which means that a fully transistorized ignition system would be no heavier than the magnetos and energy transfer systems now in use. And, the transistorized system, which is not limited by having to feed all current through a pair of points, would be capable of delivering all the sparks anyone could need for several years to come.

(Continued on Page 12)

Lucas already has such a system, and its present output limit is 60,000 sparks per minute — which is, I believe, a limit imposed by the "saturation" point of the coil. With a pair of coils, the output would be doubled and it is unlikely that anyone is going to need more than 120,000 sparks per minute for at least the rest of this season.

TRANSMISSIONS

There was a time when 3-speed transmissions were quite common, and only the better sporting models and outright racing machines had 4-speeds. Now, the 4-speed transmission is standard wear for all but super-economy models, and 5speeds are offered for many sports/touring bikes. And, of course, 5 or more speeds are becoming absolutely essential for any racing motorcycle worthy of the name.

Unfortunately, most of the equipment in the hands of private entrants is a bit dated, and so several specialty firms have begun to make racing gear sets for standard transmission cases. To date, the best of these appears to be the Schafleitner 6speed conversion for AMC (AJS, Matchless and Norton) transmissions. The Schafleitner conversion is a trifle pricey, over $500, but it will do the job as few others, and in racing nothing is cheap that does not work. Incidentally, the Schafleitner is available in either touring or racing ratios. For those who do not have the price of the Schafleitner conversion, AMC has a 5speed that is also quite good, although the gear selector mechanism requires some fiddling before it will function with any precision.

There was to be a 7-speed transmission from Morley, in England, but late reports tell us this project has been abandoned. In the Morley box, gear selection was accomplished by sliding a T piece back and forth in a hollow, slotted shaft. The ends of the T-piece extended out of the shaft and served to lock a gear at a time to the shaft, which carried the output sprocket. All of the countershaft gears were splined on the countershaft, and all of the 7 gears ran in constant mesh with mating gears that free-wheeled on the output shaft. The sliding T-piece served to lock the free gears, when required, to the output shaft. A similar arrangement has been used in other transmissions, but most designers prefer to slide the entire mainshaft back and forth, and to provide a very short set of splines to pick up the appropriate gears (which have splined hubs) and lock them to the output shaft. Such splines are much stronger than Morley's T-piece, and "that may be the reason why the Morley box is not being produced.

(Continued on Page 14)

In American road racing (where regulations permit) the 350cc kit-equipped Honda Super Hawk is very popular, and these bikes have been handicapped by transmission ratios that are not at all suitable for road racing. Most of the lads have been switching 2nd and 3rd gears, to get a 3rd and 4th combination that is rather widely spaced but usable because of the wide-range torque of the Honda engine. This works, but is something less than ideal, and I am sure that everyone will be delighted to hear that there is a special gearset available from England for the Honda which gives it 4 close, usable ratios. At this time, I am unable to provide an address and price, but I expect to have this information soon and will include it in this column as soon as it is available. Those who now have these close ratio gear sets are not particularly anxious to spread the news, for it gives them an enormous advantage.

I might also mention that there is a persistent rumor that the Honda factory will be making a close-ratio 5-speed gear set very soon, and this (if true) would be most welcome news. The present standard ratios are fine for touring, but they leave a lot to be desired in racing.

Actually, there is an advantage with 5 and 6-speed transmissions in road racing that few except those involved ever realize. As you know, classic road racing starts are made with dead engines. The riders have to push-start the machines after the flag falls, and he who can get his engine started quickly is likely to grab a lead that the laggards will find difficult to whittle away. With a 4-speed transmission, particularly one with ultra-close road racing gears, the rider must push like the very devil to get the engine started (because of the tall first gear) and then after it starts, he will have to slip the clutch and nurse the bike up to a speed where the engine really begins to pull. The contrast with a 6-speed transmission (and to a lesser extent a 5-speed) is enormous. Because there are so many ratios, 1st can be made a real stumpyanker, and all the rider has to do on the start is give the bike a big shove, and then drop the clutch as he leaps aboard. The high 1st gear ratio will crank the engine over smartly and if the tuner has done his work it will fire immediately, after which the rider simply winds on throttle and rockets away. The advantages of having another 5 usable, closely staged ratios (in addition to the first, starting gear) for the rest of the race should be so obvious as to require no further explanation.

There are disadvantages. The ratios cannot be added without some penalty in weight, and all the extra gears do create more churning losses in the transmission. In some instances, these churning losses are substantial enough to cause a noticeable drop in top speed after going from a 4-speed to a 6-speed transmission. Also, the extra ratios are a mixed blessing for the rider. He will find that he has a gear for every situation, which is all to the good; but he will also find that it is necessary to make many more shifts, and if a slow corner follows a long straight, he mav have to drop all the way from 6th to 1st. Assuming that the bike has good brakes, it is possible to lose speed so fast that it becomes quite hard to keep up with one's downshifts. In any case, you can be sure that if you miss one of the downshifts, you will arrive at the corner in the wrong gear. All this means that if a 6-SDeed transmission is to be used, the shifting mechanism must be even smoother and more positive than for a 4-speed.

(Continued on Page 16)

BEARINGS AND BUSHINGS

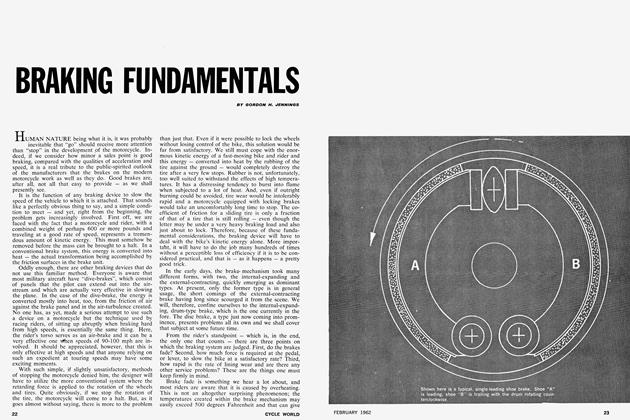

In the lune issue of CYCLE WORLD, we published a road test of the BSA Lightning Rocket, and in that report we made mention of the fact that the engine's timing-side main bearing was a bushing (rather than a ball bearing, as on the drive side) and that this bushing had been an Achilles heel in modified or otherwise overworked BSAs. Although it was made quite clear that the arrangement was comnletelv satisfactory in normal, or even near normal service, and only gave problems in modified engines, we have received a few grouchy letters from BSA lovers over the matter.

Let's set things straight. There is nothing wrong with plain bushing type bearings; they are used in countless connecting rods, and have proven at least as reliable as roller-type bearings in that difficult application. As a matter of fact, I have a single cylinder racing engine designed (as an exercise; the funds for actually building it are not available) and it features plain bearings throughout. The plain bearings are light, inexpensive and quite reliable if not overworked or subjected to the wrong kind of load. The only thing wrong with a good, tri-metal bearing is not that it isn't capable of carrying a heavy load, but that it requires copious lubrication,, and that (in the case of a main bearing) any shaft flexing will cause localized overloading — which usually leads to a failure. And, in a 2-main bearing vertical twin, high crank speeds and high gas loadings tend to flex the crank shaft. When the shaft flexes, the crank journal no longer runs straight through the bearing. Instead, it passes through at an angle, so there is a point at which it goes into the bearing where it is pulled very hard against the bearing surface, and the same applies to another point on the opposite side where it emerges from the bearing. These points of local overloading will often break through the film of lubricant and make a direct contact with the bearing metal, which starts a scuffing. Even when there is no direct contact, however, the bearing metal will actually flow away from the load points after a brief period. This will cause a "bellmouth" condition in the bearing, which not only gives a loss of oil pressure, but forces the center part of the bearing to carry a larger share of the load.

This is, I think, the problem with all vertical twins that have a plain timing side bearing. They are fine in normal service, because the men who designed the engines knew what the normal loads would be, and provided enough shaft stiffness and bearing surface. Unfortunately, modifying the engines often increases the loads beyond any designed-in margin of safety. When that happens, the crankshaft begins to flex, which bellmouths the end of the bearing and that in turn causes such a severe overloading in the center of the bearing that it fails. You will appreciate that the fault here lies not in the engine's designer, nor with the manufacturer.

The cure for this particular problem is to change over to a ball bearing, which is relatively insensitive to misalignment. This is done on hot BSA twins, and it is also done on the very successful 500cc Triumphs, which also have plain bearings on the timing side of the crank. In neither case is it any reflection on the basic engine; it only points up the extent to which these engines are being overstressed in competition. Just be glad that the engines' designers did not choose to restrict the valves and porting so much that it would be impossible to get enough power from them to overwork the bearings.